Characteristics and Mechanism of Slow Cook-off of Composite Explosive Charges

-

摘要: 为研究不同结构复合装药在慢速烤燃过程中的响应规律,分别设计了JH-2和JHB炸药的

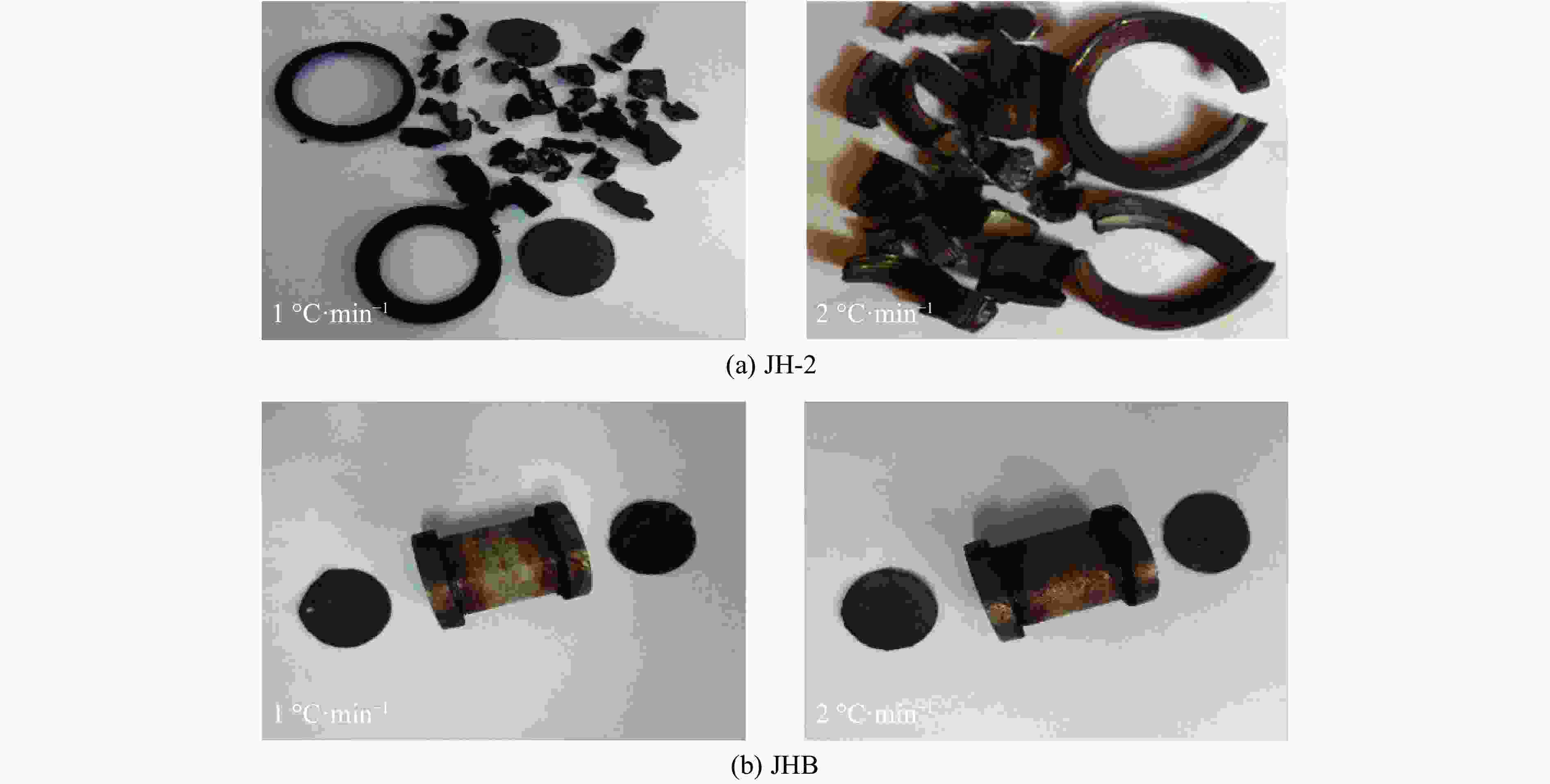

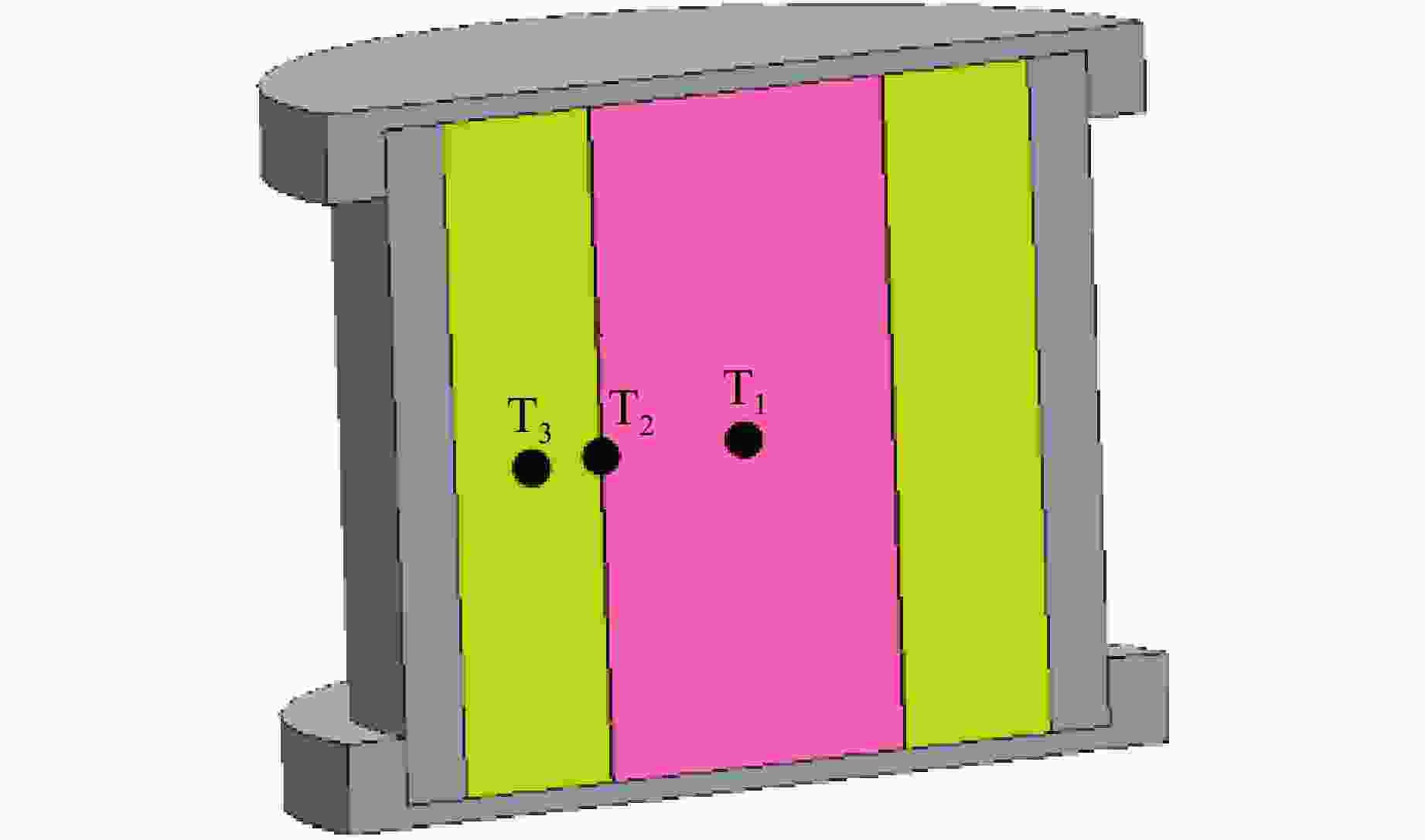

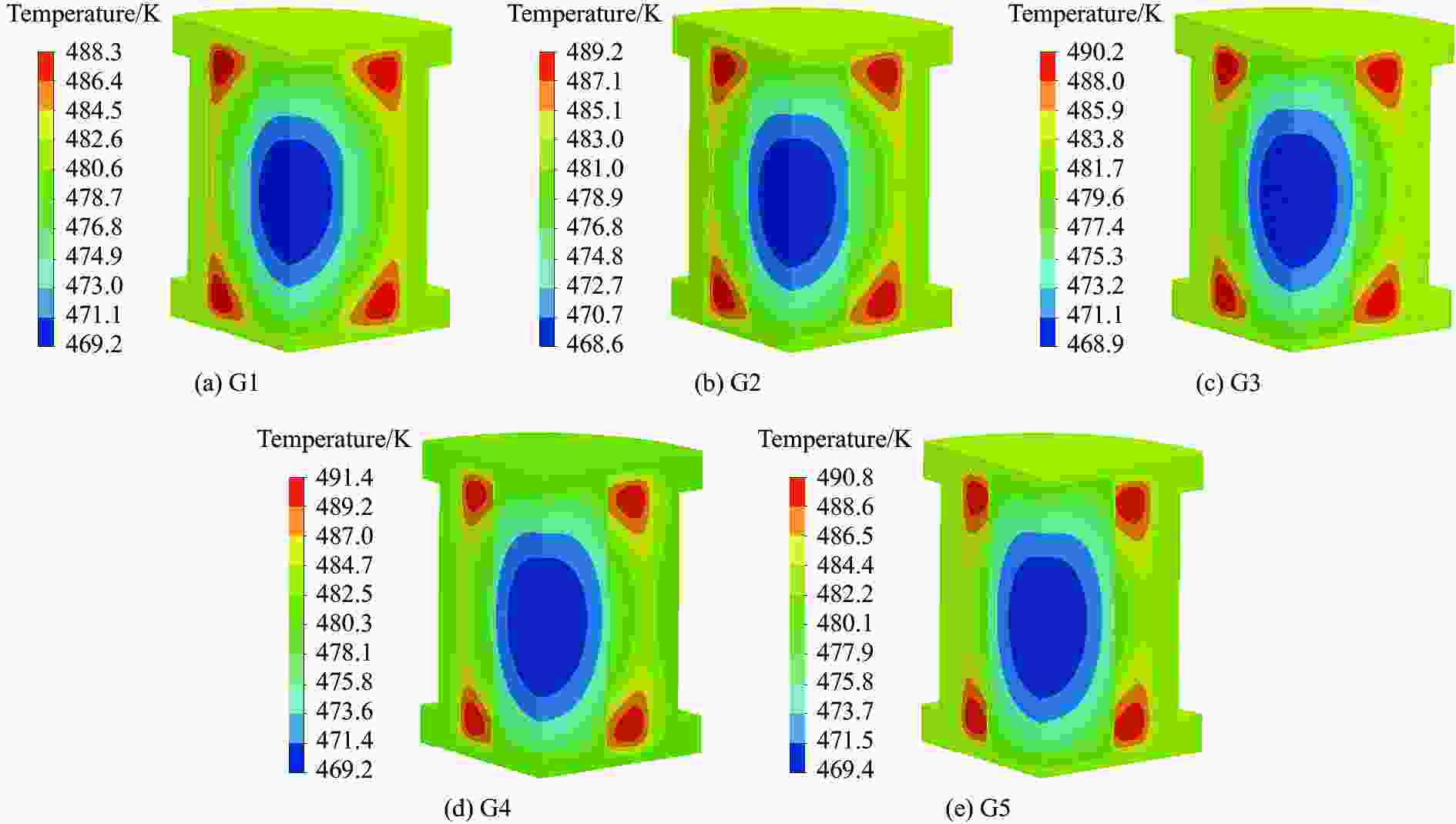

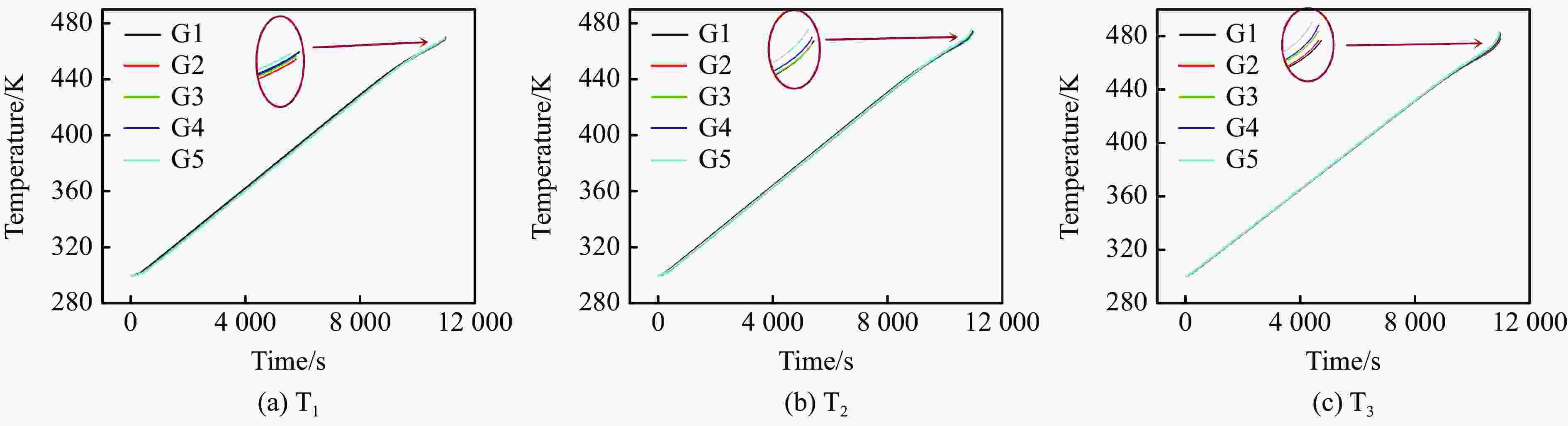

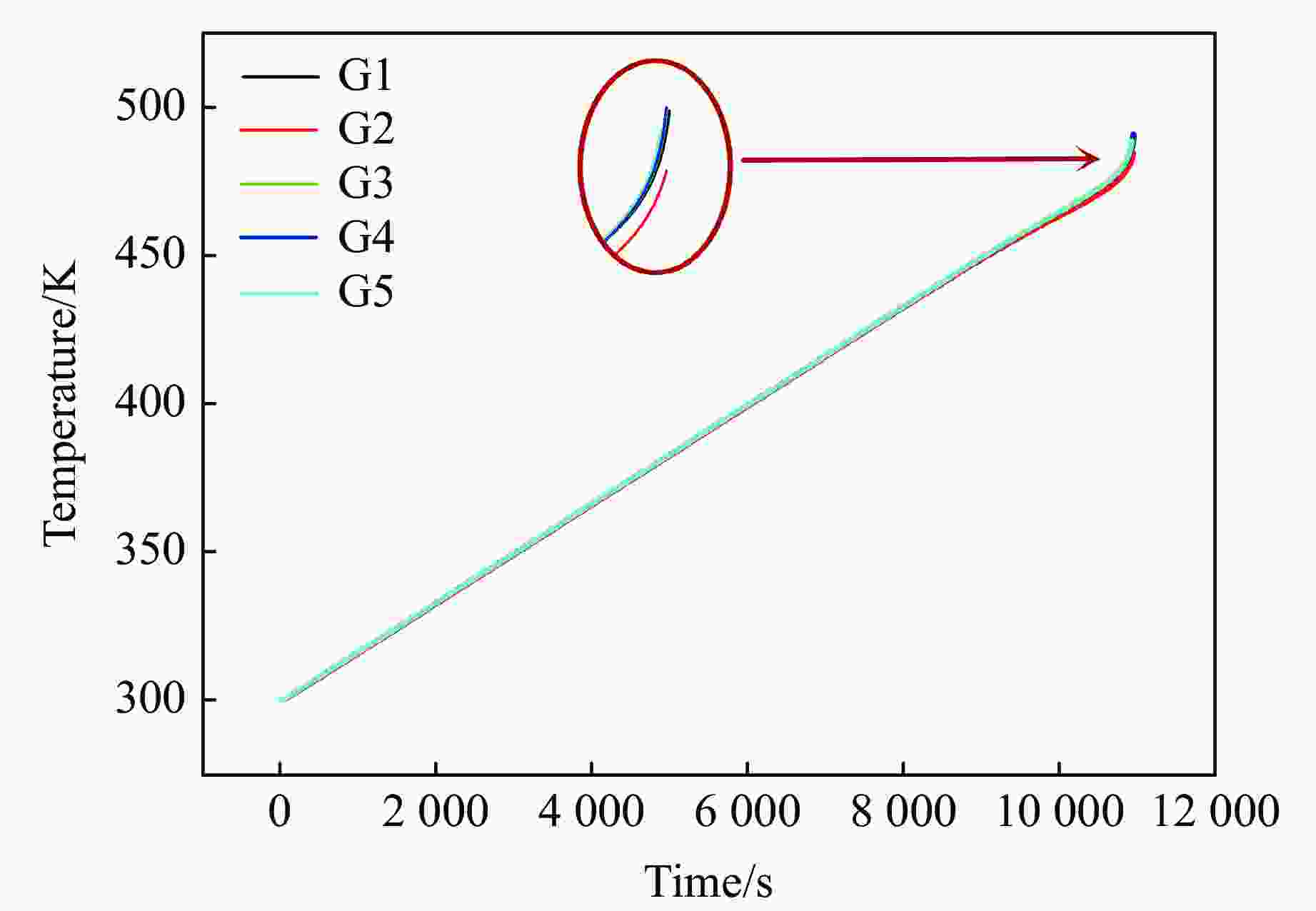

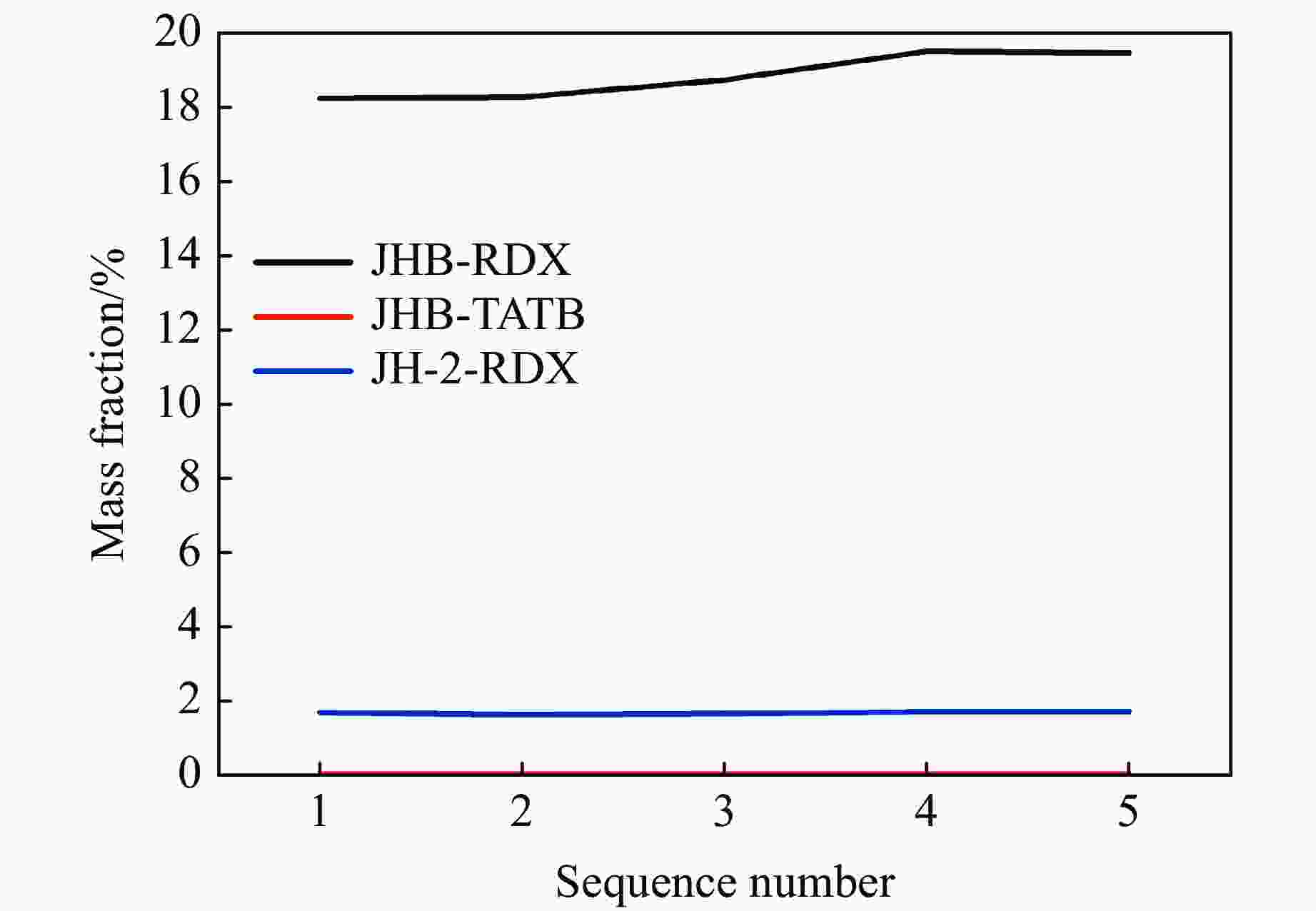

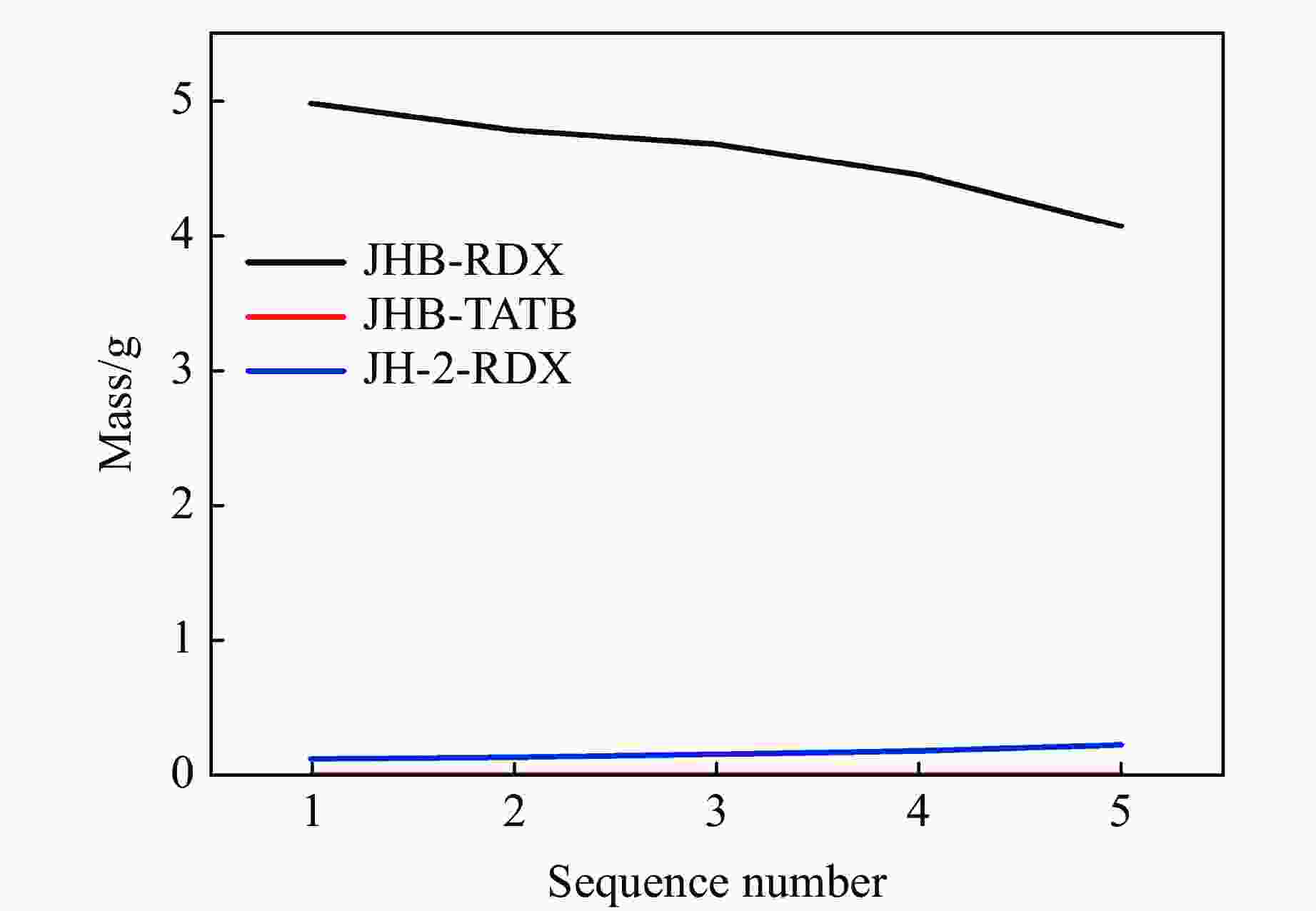

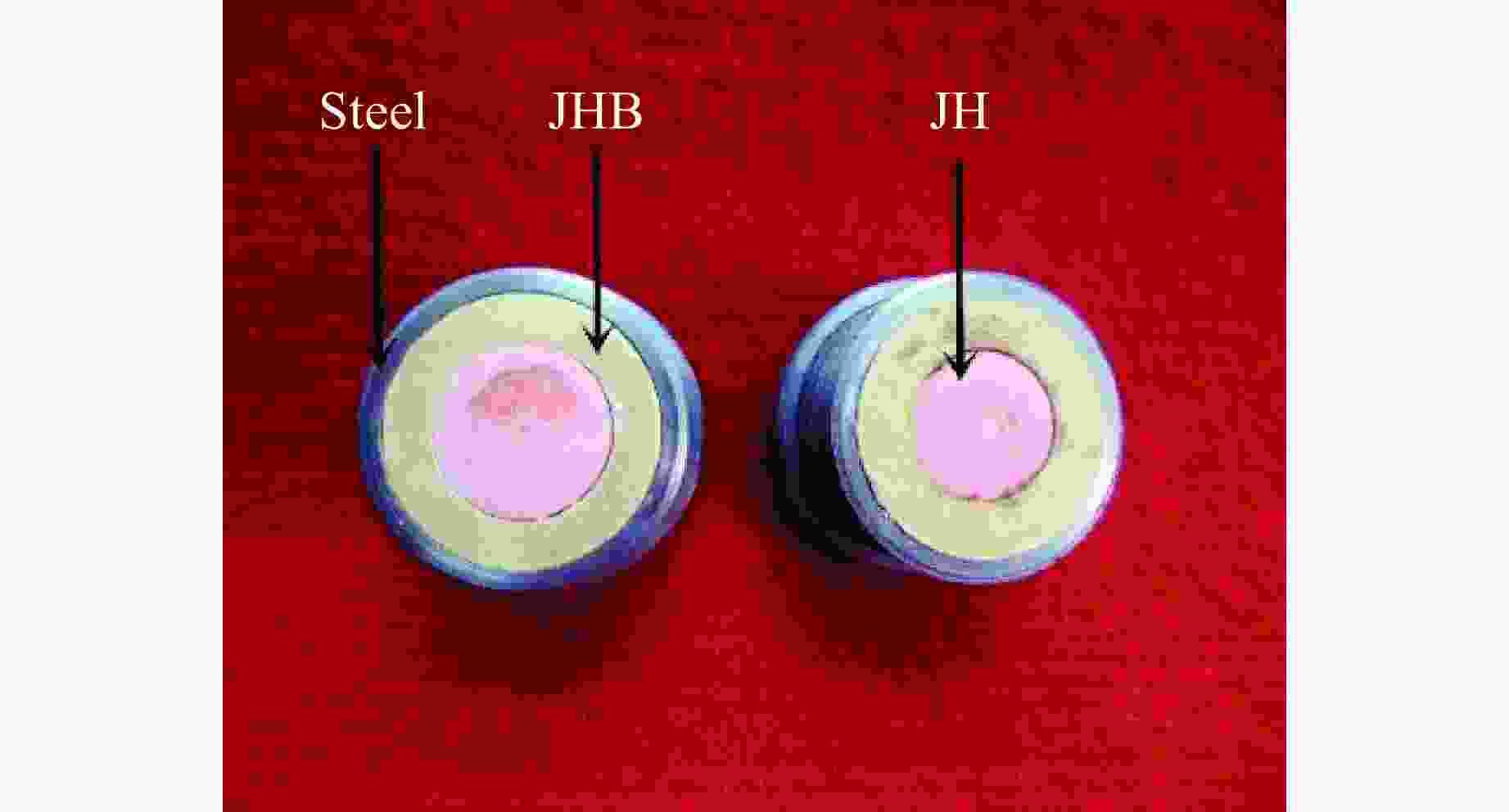

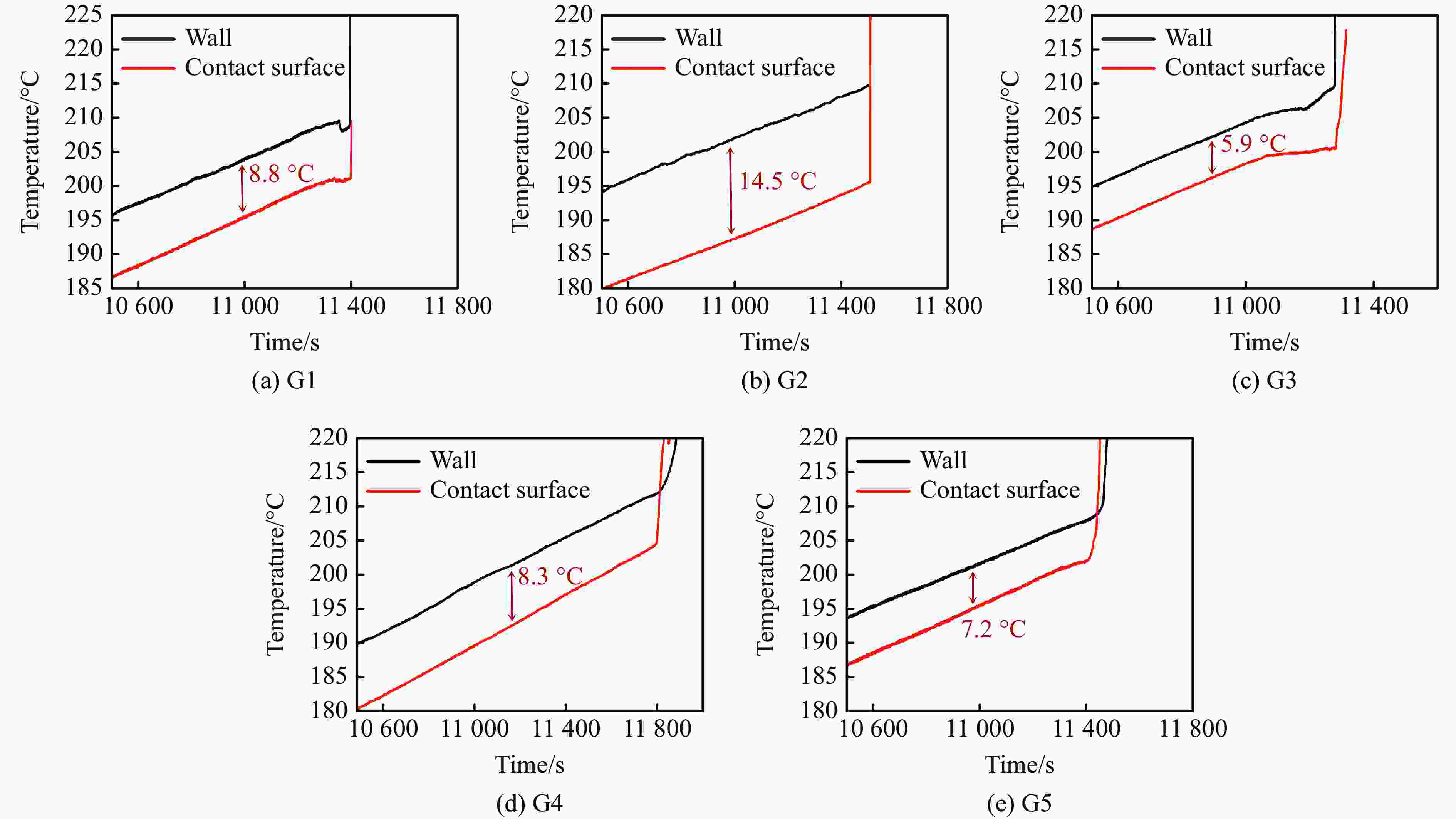

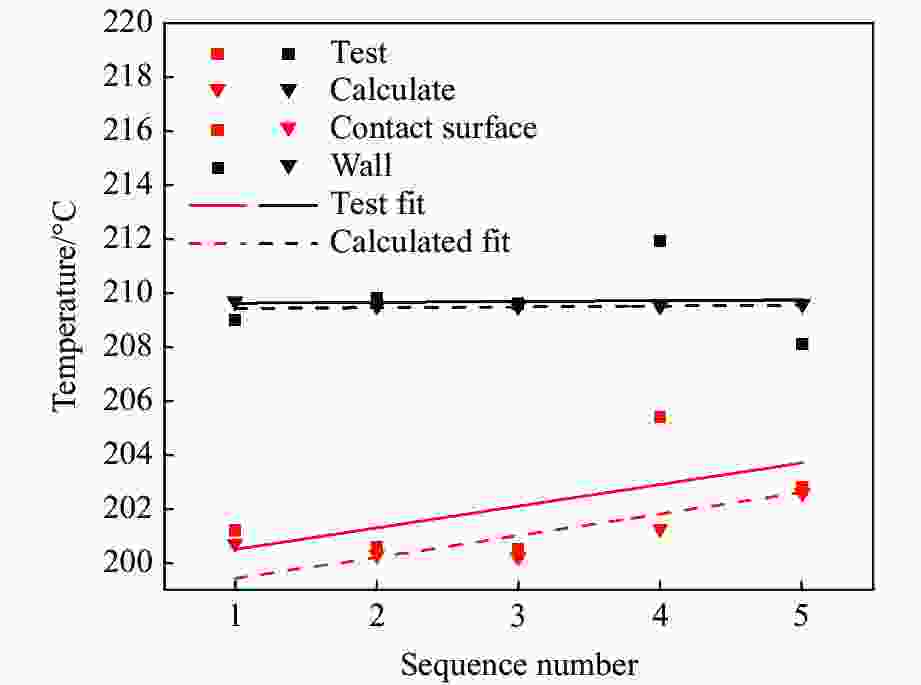

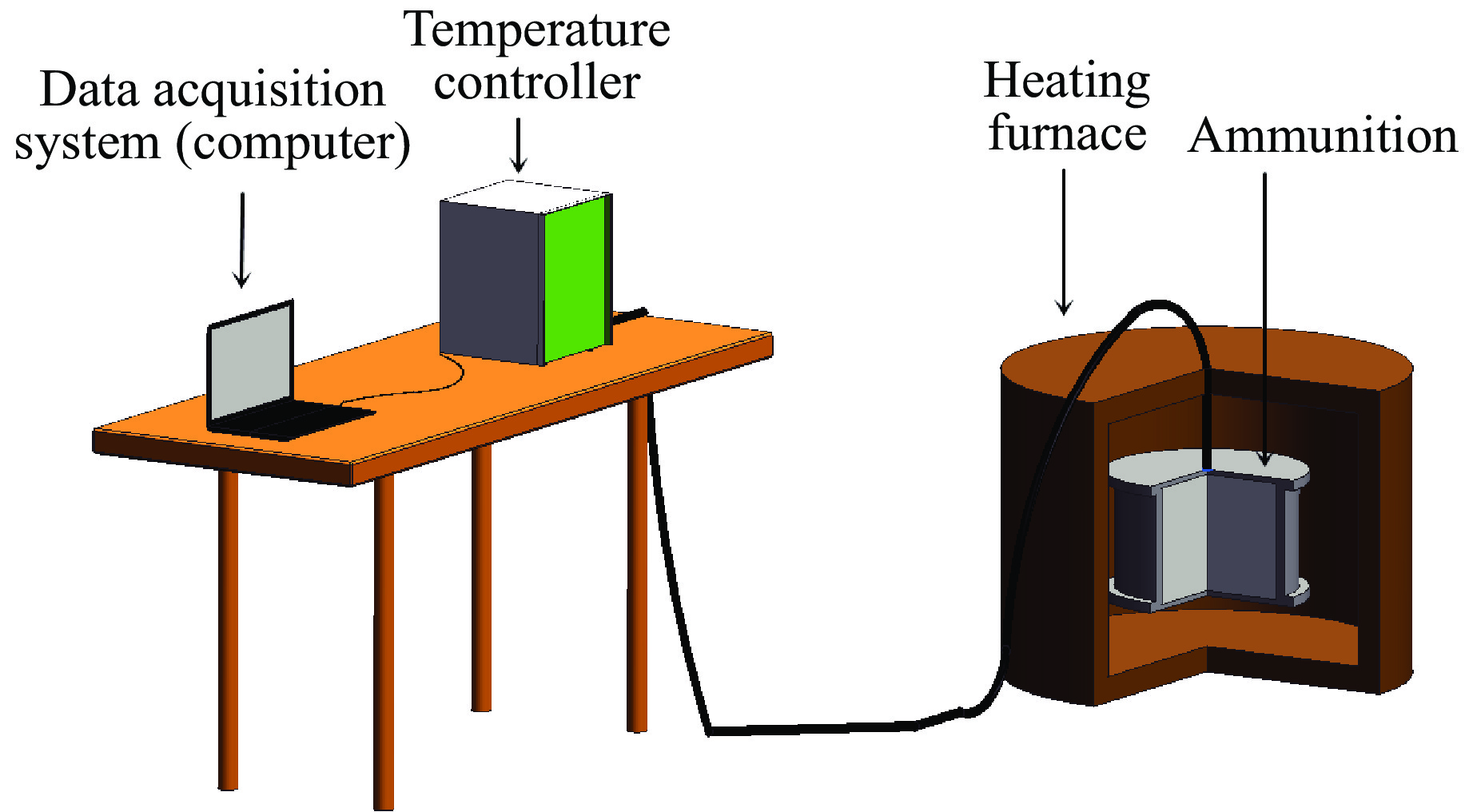

$\varnothing $ 19 mm单独药柱装药和$\varnothing $ 30 mm复合药柱装药烤燃弹,通过慢速烤燃试验分别获得了单独药柱烤燃弹在1和2 ℃·min−1升温速率、复合药柱烤燃弹在1 ℃·min−1升温速率下的温度-时间变化曲线,并结合数值模拟进一步分析了烤燃弹内部温度场的变化。研究结果表明:单独药柱装药情况下,低敏感炸药能明显降低弹药在热刺激下的响应等级;而在复合药柱装药时,烤燃弹响应点均位于外层低敏感药柱靠近壳体的环状区域,响应温度随高能药柱直径的增加而升高,响应等级随外层低敏感药柱厚度的增加而增加,复合装药由于药柱接触面存在接触热阻,烤燃弹传热受到阻滞,使得内部高能药柱极少参与反应。Abstract: In order to study the response law of composite charges with different structures in the process of slow cook-off, the cook-off bombs filled with$\varnothing $ 19 mm single charges of explosives JH-2 and JHB and$\varnothing $ 30 mm composite charges were designed. The temperature-time curves of single charges at 1 and 2 ℃·min−1and composite charges at 1 ℃·min−1 were obtained in tests, and combined with the numerical simulation to further analyzed the temperature field inside the bomb. The research results show that in the case of a single charge, the low-sensitive explosive can significantly reduce the response level of the bomb under thermal stimulation; while in the case of a composite charge, the response point of the bomb is located at the annular region of the outer low-sensitive charge near the shell. The response temperature increases with the increase of the high-energetic charge’s diameter, and the response level increases with the increase of the outer low-sensitive charge’s thickness. The heat transfer in the bomb is retarded due to the contact thermal resistance between the contact surface of composite charges, thus the inner high-energetic cylinder is rarely involved in the reaction.-

Key words:

- slow cook-off /

- composite charge /

- thermal contact resistance

-

表 1 单一药柱慢速烤燃试验结果

Table 1. Slow cook-off test results of single charges

Explosive Heating rate/(℃·min−1) No. Temperature/℃ Response time/min JH-2 1 1 209.5 183.10 2 208.9 182.70 2 3 213.7 95.85 4 214.1 96.04 JHB 1 5 208.4 182.20 6 209.6 183.30 2 7 214.3 95.63 8 213.9 94.90 表 2 炸药与壳体的物性参数

Table 2. Physical parameters of explosives and shell

Material $\;\rho $/(g∙cm−3) c/(J∙kg−1∙K−1) $\lambda $/(W∙m−1∙K−1) RDX 1 640 1 130.00 0.250 TATB 1 938 1 170.00 0.544 Steel 8 030 502.48 43.000 表 3 炸药反应动力参数

Table 3. Reaction dynamic parameters of explosives

Explosive i E/(kJ∙mol−1) Z/s−1 Q/(MJ∙kg−1) RDX 1 194 6.40×1017 –2.68 2 185 4.74×1017 8.03 3 143 9.54×1014 65.60 TATB 4 252 7.02×1020 0.21 5 176 8.75×1012 0.21 6 142 4.36×1011 –2.94 表 4 单一药柱仿真结果与试验结果的比较

Table 4. Comparison between simulation and test results for single charges

Explosive Heating rate

/(℃·min−1)Response temperature/℃ Response time/min Calculate Test Calculate Test JH-2 1 206.60 209.2 179.75 182.9 2 214.68 213.9 93.92 96.0 JHB 1 207.68 209.0 180.83 182.8 2 214.18 214.1 93.67 95.2 表 5 复合药柱试验分组与组分药柱厚度

Table 5. Test group and charge thickness of composite charges

Charge species Thickness/mm G1 G2 G3 G4 G5 JH-2 14 15 16 17 19 JHB 16 15 14 13 11 -

[1] REYNOLDS M, HUNTINGTON-THRESHER W. Development of tuneable effects warheads [J]. Defence Technology, 2016, 12(3): 255–262. doi: 10.1016/j.dt.2016.01.006 [2] ARNOLD W. Tunable charge with internal layers [J]. Procedia Engineering, 2015, 103: 4–11. doi: 10.1016/j.proeng.2015.04.002 [3] HONG X W, LI W B, CHENG W, et al. Numerical simulation of the blast wave of a multilayer composite charge [J]. Defence Technology, 2020, 16(1): 96–106. doi: 10.1016/j.dt.2019.04.007 [4] 向梅, 黄毅民, 饶国宁, 等. 不同升温速率下复合药柱烤燃实验与数值模拟研究 [J]. 爆炸与冲击, 2013, 33(4): 394–400. doi: 10.3969/j.issn.1001-1455.2013.04.010XIANG M, HUANG Y M, RAO G N, et al. Cook-off test and numerical simulation for composite charge at different heating rates [J]. Explosion and Shock Waves, 2013, 33(4): 394–400. doi: 10.3969/j.issn.1001-1455.2013.04.010 [5] 任玉新, 陈海昕. 计算流体力学基础 [M]. 北京: 清华大学出版社, 2006.REN Y X, CHEN H X. Fundamentals of computational fluid dynamics [M]. Beijing: Tsinghua University Press, 2006. [6] MCGUIRE R R, TARVER C M. Chemical-decomposition models for the thermal explosion of confined HMX, TATB, RDX, and TNT explosives [C]//Seventh Symposium on Detonation. Annapolis, Maryland, US: Office of Naval Research, 1981. [7] ABD-ELGHANY M, ELBEIH A, HASSANEIN S. Thermal behavior and decomposition kinetics of RDX and RDX/HTPB composition using various techniques and methods [J]. Central European Journal of Energetic Materials, 2016, 13(3): 714–735. doi: 10.22211/cejem/64954 [8] TARVER C M, KOERNER J G. Effects of endothermic binders on times to explosion of HMX- and TATB-based plastic bonded explosives [J]. Journal of Energetic Materials, 2007, 26(1): 1–28. doi: 10.1080/07370650701719170 [9] WEN Q, WANG Y S, WANG G Y, et al. Numerical analysis of response of a fuze to cook-off [J]. Journal of Energetic Materials, 2019, 37(3): 340–355. doi: 10.1080/07370652.2019.1615580 [10] 徐瑞, 智小琦, 王帅. 缓释结构对B炸药烤燃响应烈度的影响 [J]. 高压物理学报, 2021, 35(3): 035201. doi: 10.11858/gywlxb.20200657XU R, ZHI X Q, WANG S. Influence of venting structure on the cook-off response intensity of composition B [J]. Chinese Journal of High Pressure Physics, 2021, 35(3): 035201. doi: 10.11858/gywlxb.20200657 [11] HU M, YU D M, WEI J B. Thermal conductivity determination of small polymer samples by differential scanning calorimetry [J]. Polymer Testing, 2007, 26(3): 333–337. doi: 10.1016/j.polymertesting.2006.11.003 [12] 丁洋, 赵生伟, 初哲, 等. 激光辐照带壳炸药热点火数值计算模型 [J]. 现代应用物理, 2017, 8(3): 031001.DING Y, ZHAO S W, CHU Z, et al. Modeling of thermal ignition of explosive with metal shell irradiated by laser beam [J]. Modern Applied Physics, 2017, 8(3): 031001. [13] WETHTHIMUNI M L, CAPSONI D, MALAGODI M, et al. Shellac/nanoparticles dispersions as protective materials for wood [J]. Applied Physics A, 2016, 122(12): 1058. doi: 10.1007/s00339-016-0577-7 [14] GU J, LI H, ZHAO X, et al. Kinetic modeling of liquid phase RDX thermal decomposition process and its application in the slow cook-off test prediction [J]. Propellants, Explosives, Pyrotechnics, 2021, 46(6): 935–943. doi: 10.1002/prep.202000291 [15] GNANAPRAKASH K, CHAKRAVARTHY S R, JAYARAMAN K, et al. Combustion behaviour of composite sandwich propellants containing RDX [J]. Proceedings of the Combustion Institute, 2021, 38(3): 4451–4459. doi: 10.1016/j.proci.2020.06.387 -

下载:

下载: