Research Progress on the Application of Ultra-High Pressure Combined with Other Preservation Technologies in Aquatic Products

-

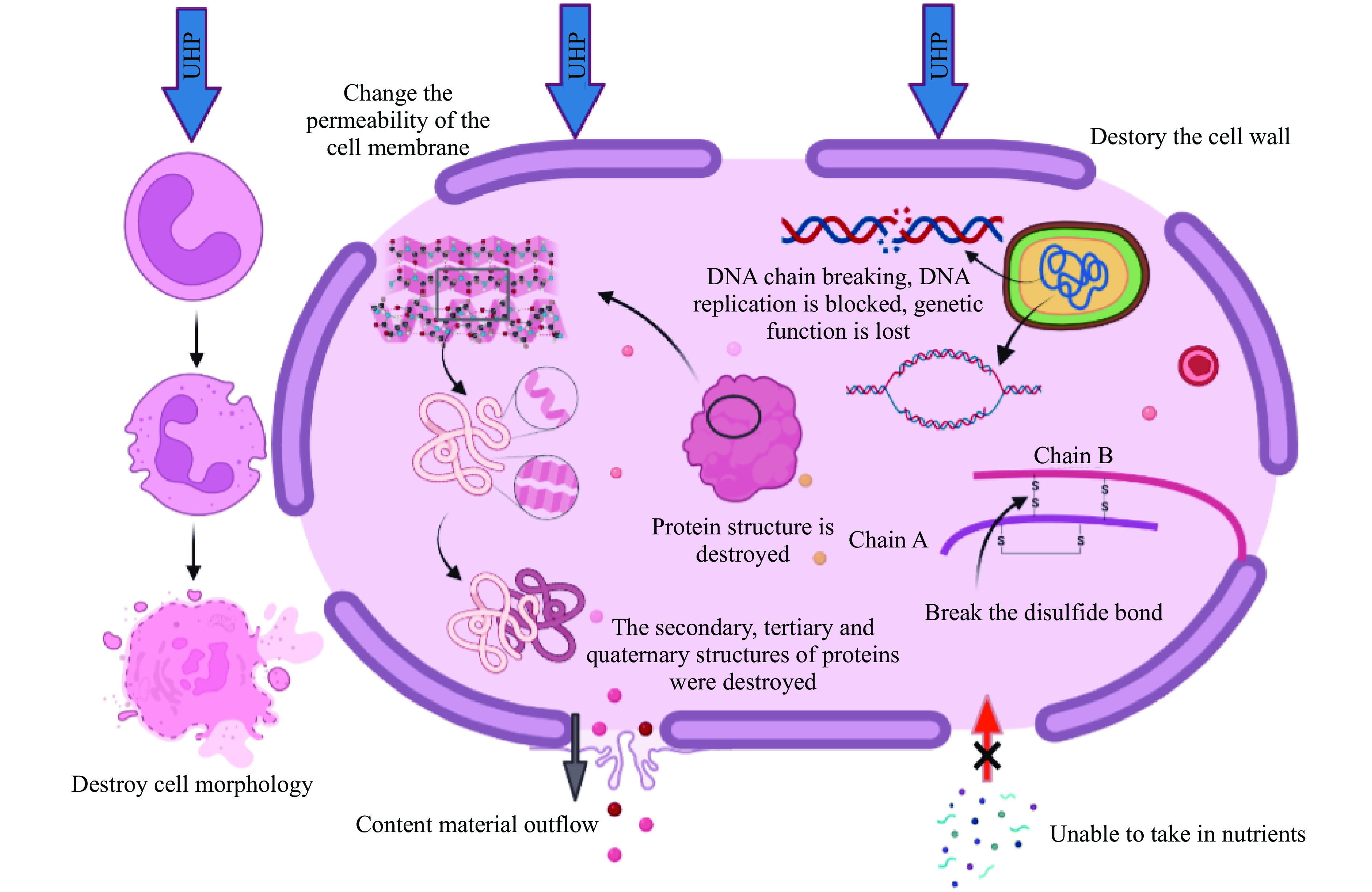

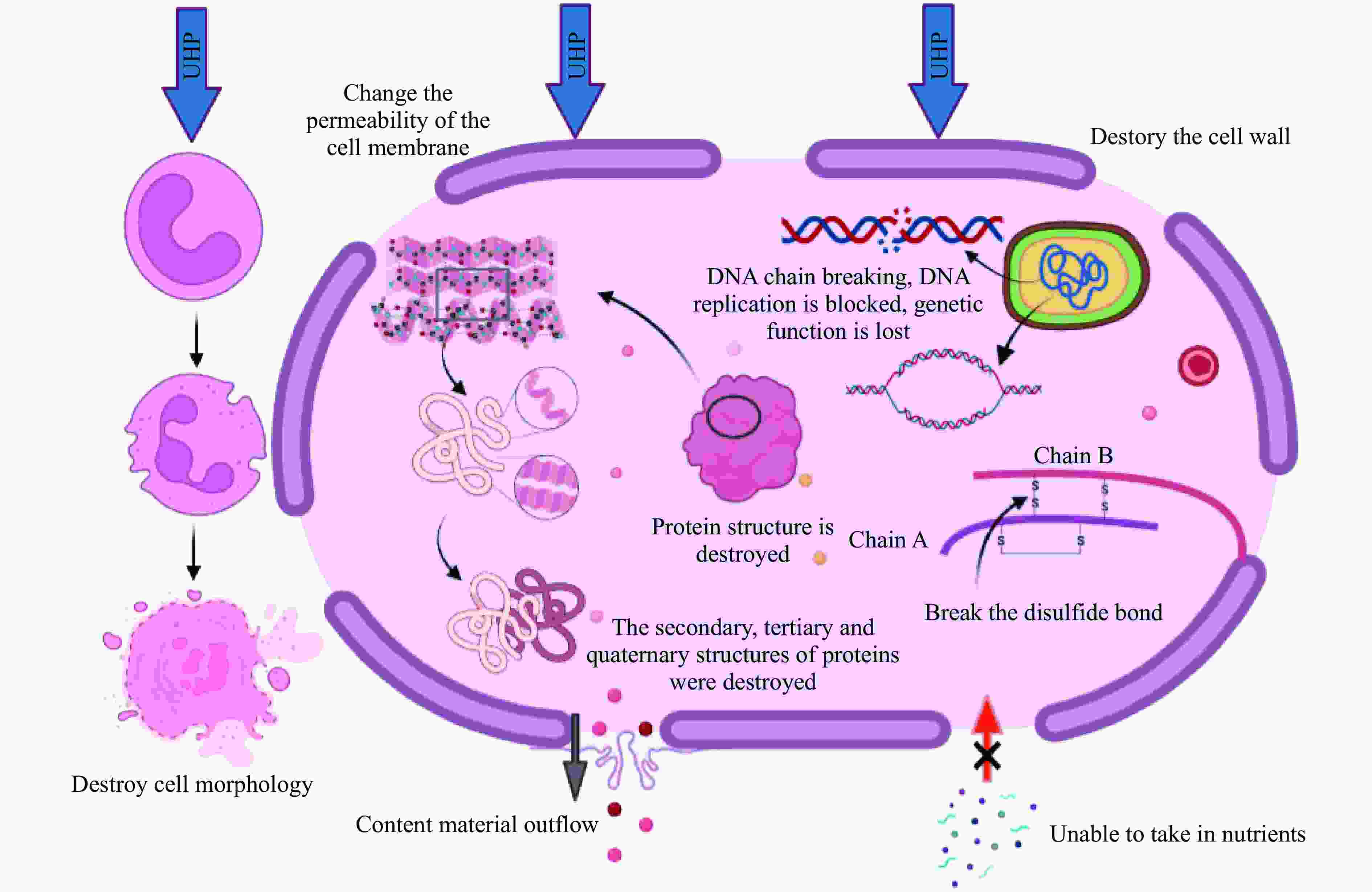

摘要: 水产品捕捞后,由于微生物与内源酶的作用,在脂肪氧化等其他因素的影响下,感官品质下降,采用适当的处理手段可以延缓其劣变。超高压技术具有压力传递均匀、杀菌效果好、灭酶彻底等特点,能保全食品加工前的色泽、香味及各类营养成分,同时还可以赋予食品新的口感,具有低能耗、高效率、无二次污染、操作简便等优点。在介绍超高压处理技术主要优缺点、工作原理与作用机制的基础上,阐述了该技术在水产品灭菌、钝酶与加工改性等方面的应用研究进展,提出超高压处理可联合物理、化学及生物保鲜技术提升作用效果,并对超高压技术在水产品中的发展前景予以展望。Abstract: The quality of aquatic products decreases after fishing due to the action of microorganisms, endogenous enzymes, lipid oxidation, and other factors. Appropriate treatment can delay aquatic products deterioration. The ultra-high pressure technology (UHP) has the advantages of uniform pressure transmission, good sterilization and enzyme inactivation effect, low energy consumption, high efficiency, no secondary pollution, and simple operation. UHP can not only remain the original color, flavor and various nutrients of food, but also give food a new taste. Based on the introduction of main advantages, disadvantages and working principle of UHP, the research progress of UHP technology in sterilization, enzyme inactivation and processing modification of aquatic products were summarized. UHP combined with physical, chemical and biological preservation technologies can improve sterilization and enzyme inactivation effect and food quality, and the future development of UHP technology in aquatic products was prospected.

-

表 1 常用的水产品物理保鲜方式及其主要特点及应用实例

Table 1. Common physical preservation methods and main characteristics of aquatic products

Methods Advantages Disadvantages References Cryopreservation Simple operation, low cost and

wide application rangeThe sensory quality is affected, and some

methods have short shelf life or high

requirements for equipmentHu, et al.[8]

Liu, et al.[9]

Chen, et al.[10]Modified atmosphere preservation Safe and efficient,

long storage timeExpensive equipment, high concentration

of CO2 lead to the decline of water holding

capacity, and affect the flavor and tasteDewi, et al.[11]

Das, et al.[12]

Esteves, et al.[13]Ultra-high pressure processing Sterilization is efficient and complete,

energy saving and environmental

protection, high safety and

good food tasteThe cost is high, affect the appearance of food, and some foods are slightly cooked Wang, et al.[14]

Luo, et al.[15] -

[1] 陈丽兵. 渔业经济发展现状及对策分析 [J]. 山西农经, 2021(12): 128–129.CHEN L B. Fishery economic development status and countermeasure analysis [J]. Shanxi Agricultural Economics, 2021(12): 128–129. [2] HU F, ZHONG H, WU C, et al. Development of fisheries in China [J]. Reproduction and Breeding, 2021, 1(1): 64–79. doi: 10.1016/j.repbre.2021.03.003 [3] ODEYEMI O A, ALEGBELEYE O O, STRATEVA M, et al. Understanding spoilage microbial community and spoilage mechanisms in foods of animal origin [J]. Comprehensive Reviews in Food Science and Food Safety, 2020, 19(2): 311–331. doi: 10.1111/1541-4337.12526 [4] MEI J, MA X, XIE J. Review on natural preservatives for extending fish shelf life [J]. Foods, 2019, 8(10): 490. doi: 10.3390/foods8100490 [5] MAHMUD A, ABRAHA B, SAMUEL M, et al. Fish preservation: a multi-dimensional approach [J]. MOJ Food Processing & Technology, 2018, 6: 303–310. [6] 陈卫明, 赵卉双, 钟机, 等. 水产品物理保鲜技术与应用 [J]. 科学养鱼, 2016(3): 76–79.CHEN W M, ZHAO H S, ZHONG J, et al. Fresh-keeping technology and application of aquatic products logistics [J]. Scientific Fish Farming, 2016(3): 76–79. [7] TAVARES J, MARTINS A, FIDALGO L G, et al. Fresh fish degradation and advances in preservation using physical emerging technologies [J]. Foods, 2021, 10(4): 780. doi: 10.3390/foods10040780 [8] HU Y, ZHANG N, WANG H, et al. Effects of pre-freezing methods and storage temperatures on the qualities of crucian carp (Carassius auratus var. pengze) during frozen storage [J]. Journal of Food Processing and Preservation, 2021, 45(2): e15139. [9] 刘迟, 李保国, 李亚伦, 等. 大黄鱼低温保鲜技术研究进展 [J]. 包装与食品机械, 2020, 38(1): 64–67, 72. doi: 10.3969/j.issn.1005-1295.2020.01.014LIU C, LI B G, LI Y L, et al. Progress in research of low temperature preservation technology of Pseudosciaena crocea [J]. Packaging and Food Machinery, 2020, 38(1): 64–67, 72. doi: 10.3969/j.issn.1005-1295.2020.01.014 [10] 陈胜军, 陶飞燕, 潘创, 等. 虾产品低温贮藏保鲜技术研究进展 [J]. 中国渔业质量与标准, 2020, 10(1): 68–75. doi: 10.3969/j.issn.2095-1833.2020.01.008CHEN S J, TAO F Y, PAN C, et al. Research progress in low-temperature storage and fresh-keeping technology of shrimp products [J]. Chinese Fishery Quality and Standards, 2020, 10(1): 68–75. doi: 10.3969/j.issn.2095-1833.2020.01.008 [11] DEWI F R, POWELL S M, STANLEY R A. The effects of pre-processing sanitation and modified atmosphere packaging on microbial growth in bulk packs of Atlantic salmon (Salmo salar) fillets [C]//IOP Conference Series: Earth and Environmental Science. Bristol, UK: IOP Publishing, 2021, 733(1): 012081. [12] DAS K C, ALICE E J, HOSSAIN M A, et al. Effects of vacuum and modified atmosphere packaging on the shelf life of Rohu fish (Labeo rohita) stored at refrigerated temperature (4℃) [J]. International Food Research Journal, 2021, 28(3): 586–593. [13] ESTEVES E, GUERRA L, ANIBAL J. Effects of vacuum and modified atmosphere packaging on the quality and shelf-life of gray triggerfish (Balistes capriscus) fillets [J]. Foods, 2021, 10(2): 250. doi: 10.3390/foods10020250 [14] 王娜, 潘雅燕, 姜薇. 超高压技术在鱼类产品保鲜中的应用 [J]. 四川旅游学院学报, 2020(6): 14–17. doi: 10.3969/j.issn.1008-5432.2020.06.004WANG N, PAN Y Y, JIANG W. The application of ultra-high pressure technology in the preservation of fish products [J]. Journal of Sichuan Higher Institute of Cuisine, 2020(6): 14–17. doi: 10.3969/j.issn.1008-5432.2020.06.004 [15] 骆方杰. 超高压技术在水产品保鲜加工中的应用分析 [J]. 食品安全导刊, 2020(9): 154.LUO F J. Application analysis of ultra-high pressure technology in the preservation and processing of aquatic products [J]. China Food Safety Magazine, 2020(9): 154. [16] FAM S N, KHOSRAVI K, MASSOUD R, et al. High-pressure processing in food [J]. Biointerface Research in Applied Chemistry, 2021, 11(4):11553–11561. [17] WEIPING T, SHIYI W, WEI J. Effects of ultra-high pressure treatment on aroma components of braised mandarin fish [C]//IOP Conference Series: Earth and Environmental Science. Bristol, UK: IOP Publishing, 2020, 565(1): 012063. [18] SHI L, XIONG G, YIN T, et al. Effects of ultra-high pressure treatment on the protein denaturation and water properties of red swamp crayfish (Procambarus clarkia) [J]. LWT, 2020, 133: 110124. doi: 10.1016/j.lwt.2020.110124 [19] 赵晗宇, 张志祥, 宣晓婷, 等. 超高压对食品品质与特性的影响及研究进展 [J]. 食品研究与开发, 2018, 39(10): 209–214. doi: 10.3969/j.issn.1005-6521.2018.10.039ZHAO H Y, ZHANG Z X, XUAN X T, et al. Effect of ultra-high pressure on food quality and characteristics and its research progress [J]. Food Research and Development, 2018, 39(10): 209–214. doi: 10.3969/j.issn.1005-6521.2018.10.039 [20] LUO H, SHENG Z, GUO C, et al. Quality attributes enhancement of ready-to-eat hairtail fish balls by high-pressure processing [J]. LWT, 2021, 147: 111658. doi: 10.1016/j.lwt.2021.111658 [21] SEHRAWAT R, KAUR B P, NEMA P K, et al. Microbial inactivation by high pressure processing: principle, mechanism and factors responsible [J]. Food Science and Biotechnology, 2021, 30(1): 19–35. doi: 10.1007/s10068-020-00831-6 [22] HUANG H W, HSU C P, WANG C Y. Healthy expectations of high hydrostatic pressure treatment in food processing industry [J]. Journal of Food and Drug Analysis, 2020, 28(1): 1–13. doi: 10.1016/j.jfda.2019.10.002 [23] GOVARIS A, PEXARA A. Inactivation of foodborne viruses by high-pressure processing (HPP) [J]. Foods, 2021, 10(2): 215. doi: 10.3390/foods10020215 [24] 蓝蔚青, 张溪, 赵宏强, 等. 超高压处理对腐败希瓦氏菌的影响 [J]. 中国食品学报, 2020, 20(6): 122–127.LAN W Q, ZHANG X, ZHAO H Q, et al. Effect of high hydrostatic pressure (HHP) treatment conditions on Shewanella putrefaciens [J]. Journal of Chinese Institute of Food Science and Technology, 2020, 20(6): 122–127. [25] BOLUMAR T, ORLIEN V, SIKES A, et al. High-pressure processing of meat: molecular impacts and industrial applications [J]. Comprehensive Reviews in Food Science and Food Safety, 2021, 20(1): 332–368. doi: 10.1111/1541-4337.12670 [26] 赵宏强, 蓝蔚青, 张皖君, 等. 超高压技术在水产品杀菌保鲜中的研究进展 [J]. 食品工业科技, 2016, 37(22): 369–373.ZHAO H Q, LAN W Q, ZHANG W J, et al. Research progress on the application of ultra high pressure for the preservation and sterilization of aquatic products [J]. Science and Technology of Food Industry, 2016, 37(22): 369–373. [27] 陈扬易, 谢晶, 钟小凡, 等. 超高压处理技术在水产品保鲜中的研究进展 [J]. 食品与机械, 2015, 31(4): 266–270.CHEN Y Y, XIE J, ZHONG X F. Research progress on ultra-high pressure technology for preservation of aquatic products [J]. Food & Machinery, 2015, 31(4): 266–270. [28] 罗华彬, 盛珍珍, 司永利, 等. 超高压处理对冷藏带鱼鱼丸保鲜效果的影响 [J]. 食品科学, 2021, 42(1): 157–162. doi: 10.7506/spkx1002-6630-20191202-005LUO H B, SHENG Z Z, SI Y L, et al. Effect of ultra-high pressure on quality preservation of hairtail fish balls during refrigerated storage [J]. Food Science, 2021, 42(1): 157–162. doi: 10.7506/spkx1002-6630-20191202-005 [29] 赵宏强, 吴金鑫, 张苑怡, 等. 超高压处理对冷藏鲈鱼片品质及组织结构变化的影响 [J]. 高压物理学报, 2017, 31(4): 494–504. doi: 10.11858/gywlxb.2017.04.019ZHAO H Q, WU J X, ZHANG Y Y, et al. The effect of ultra-high pressure treatment on the quality and tissue structure of refrigerated sea bass fillets [J]. Chinese Journal of High Pressure Physics, 2017, 31(4): 494–504. doi: 10.11858/gywlxb.2017.04.019 [30] SUEMITSU L, CRISTIANINI M. Effects of high pressure processing (HPP) on quality attributes of tilapia (Oreochromis niloticus) fillets during refrigerated storage [J]. LWT, 2019, 101: 92–99. doi: 10.1016/j.lwt.2018.11.028 [31] 邱春江. 超高压对鲢鱼中关键酶与结构蛋白质构影响的研究[D]. 无锡: 江南大学, 2014.QIU C J. Effect of ultra-high pressure technology on key enzymes and structural proteins in silver carp processing [D]. Wuxi: Jiangnan University, 2014. [32] MÉNDEZ L, FIDALGO L G, PAZOS M, et al. Lipid and protein changes related to quality loss in frozen sardine (Sardina pilchardus) previously processed under high-pressure conditions [J]. Food and Bioprocess Technology, 2017, 10(2): 296–306. doi: 10.1007/s11947-016-1815-x [33] TEIXEIRA B, FIDALGO L, MENDES R, et al. Changes of enzymes activity and protein profiles caused by high-pressure processing in sea bass (Dicentrarchus labrax) fillets [J]. Journal of Agricultural and Food Chemistry, 2013, 61(11): 2851–2860. doi: 10.1021/jf3049643 [34] LI G S, CHEN Y T, XUAN S F, et al. Effect of ultra high pressure pretreatment on the quality of Sole Nocera melantho meat in frozen storage [J]. Journal of Nuclear Agricultural Sciences, 2019, 33(6): 1131. [35] 马荣荣. 超高压技术对鳗鱼鱼糜品质和肌原纤维蛋白性能的影响及其关联性的研究[D]. 厦门: 厦门大学, 2019.MA R R. Effects of high hydrostatic pressure on the quality of eel surimi and the properties of myofibrillar protein and the correlation between them [D]. Xiamen: Xiamen University, 2019. [36] 崔燕, 林旭东, 康孟利, 等. 超高压协同冷冻脱壳对南美白对虾品质的影响 [J]. 现代食品科技, 2018, 34(10): 171–178.CUI Y, LIN X D, KANG M L, et al. Effect of high hydrostatic pressure combined with freezing on the shucking and quality of Penaeus vannamei [J]. Modern Food Science and Technology, 2018, 34(10): 171–178. [37] 王汇川, 张志祥, 宣晓婷, 等. 超高压对鲈鱼鱼糜品质与凝胶特性的影响 [J]. 食品研究与开发, 2018, 39(13): 13–17. doi: 10.3969/j.issn.1005-6521.2018.13.003WANG H C, ZHANG Z X, XUAN X T, et al. Effect of ultra-high pressure treatment on quality and gel characteristics of perch surimi [J]. Food Research and Development, 2018, 39(13): 13–17. doi: 10.3969/j.issn.1005-6521.2018.13.003 [38] 张智铭, 仪淑敏, 李学鹏, 等. 超高压对未漂洗金线鱼鱼糜凝胶特性的影响 [J]. 食品工业科技, 2021, 42(1): 42–47, 53.ZHANG Z M, YI S M, LI X P, et al. Effect of ultra-high pressure on gel properties of unwashed Nemipterus virgatus surimi [J]. Science and Technology of Food Industry, 2021, 42(1): 42–47, 53. [39] 王健一. 超高压处理对低盐鱼糜制品品质特性影响的研究[D]. 福州: 福建农林大学, 2018.WANG J Y. Effect of ultra-high pressure treatment on the qualities of low salt surimi [D]. Fuzhou: Fujian Agriculture and Forestry University, 2018. [40] 叶安妮. 超高压处理不同水产品的品质变化及其机理研究[D]. 广州: 华南理工大学, 2019.YE A N. Study on high pressure process on quality change of different aquatic products and its mechanism [D]. Guangzhou: South China University of Technology, 2019. [41] 陈晓梅. 超高压处理对鲮鱼肉品质及其凝胶特性的研究[D]. 广州: 仲恺农业工程学院, 2020.CHEN X M. Effect of ultra-high pressure treatment on quality and eel properties of Cirrhinus molitorella [D]. Guangzhou: Zhongkai College of Agricultural Engineering, 2020. [42] PEREZ-WON M, LEMUS-MONDACA R, HERRRERA-LAVADOS C, et al. Combined treatments of high hydrostatic pressure and CO2 in Coho Salmon (Oncorhynchus kisutch): effects on enzyme inactivation, physicochemical properties, and microbial shelf life [J]. Foods, 2020, 9(3): 273. doi: 10.3390/foods9030273 [43] 谢晶, 杨茜, 张新林, 等. 超高压技术结合气调包装保持冷藏带鱼品质 [J]. 农业工程学报, 2015, 31(12): 246–252. doi: 10.11975/j.issn.1002-6819.2015.12.033XIE J, YANG X, ZHANG X L, et al. High hydrostatic pressure treatment combined with modified atmosphere package keeping quality characteristic of Trichiurus lepturus during cold storage [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(12): 246–252. doi: 10.11975/j.issn.1002-6819.2015.12.033 [44] RODE T M, HOYDA M B, ROTABAKK B T. Favourable effects of soluble gas stabilization and modified atmosphere for suppressing regrowth of high pressure treated Listeria innocua [J]. Food Control, 2015, 51: 108–113. doi: 10.1016/j.foodcont.2014.11.006 [45] 张文杰. 扇贝在微波杀菌过程中介电特性的研究[D]. 青岛: 中国海洋大学, 2014.ZHANG W J. Study on dielectric properties of scallop during microwave sterilization [D]. Qingdao: Ocean University of China, 2014. [46] ABO BAKR T M. Microwave applications in food processing: an overview [J]. Alexandria Journal of Food Science and Technology, 2020, 17(2): 11–22. doi: 10.21608/ajfs.2020.150658 [47] GUZIK P, KULAWIK P, ZAJAC M, et al. Microwave applications in the food industry: an overview of recent developments [J]. Critical Reviews in Food Science and Nutrition, 2021: 1–20. [48] 袁龙. 软包装食品超高压及其微波协同杀菌工艺与动力学研究[D]. 无锡: 江南大学, 2017.YUAN L. Research on the inactivation process and kinetic of high hydrostatic pressure (HHP) and its microwave combined method of soft-packing food [D]. Wuxi: Jiangnan University, 2017. [49] TRINETTA V, LINTON R H, MORGAN M T. The application of high-concentration short-time chlorine dioxide treatment for selected specialty crops including Roma tomatoes (Lycopersicon esculentum), cantaloupes (Cucumis melo ssp. melo var. Cantaloupensis) and strawberries (Fragaria×ananassa) [J]. Food Microbiology, 2013, 34(2): 296–302. doi: 10.1016/j.fm.2012.12.010 [50] 王丽萍. 黄泥螺超高压栅栏杀菌技术及机理研究 [D]. 上海: 上海交通大学, 2018.WANG L P. Study on sterilizing and mechanism of high pressure processing hurdle technology for mud snail (Buttacta exarata) [D]. Shanghai: Shanghai Jiaotong University, 2018. [51] 杜苏萍, 张昭寰, 娄阳, 等. 酸性电解水结合超高压技术对虾仁中副溶血性弧菌风险降低的研究 [J]. 现代食品科技, 2016, 32(11): 146–154.DU S P, ZHANG Z H, LOU Y, et al. Risk reduction assessment of combined acidic electrolyzed water and high hydrostatic pressure effects on Vibrio parahaemolyticus in shelled shrimp [J]. Modern Food Science and Technology, 2016, 32(11): 146–154. [52] 蔡路昀, 马帅, 曹爱玲, 等. 6-姜酚协同超高压处理对冷藏海鲈鱼品质的影响 [J]. 中国食品学报, 2017, 17(11): 158–165.CAI L Y, MA S, CAO A L, et al. The effect of 6-gingerol and ultra-high pressure treatment on the quality of frozen sea bass [J]. Journal of Chinese Institute of Food Science and Technology, 2017, 17(11): 158–165. [53] 郭丽萍, 乔宇, 熊光权, 等. 复合保鲜剂协同超高压对鲈鱼贮藏品质的影响 [J]. 食品工业科技, 2019, 40(1): 269–274.GUO L P, QIAO Y, XIONG G Q, et al. Effect of compound preservatives with ultra high pressure on storage quality of the Largemouth bass [J]. Science and Technology of Food Industry, 2019, 40(1): 269–274. [54] 廖涵. 乳酸链球菌素(Nisin)与超高压结合对E.coli的协同杀菌效应 [J]. 食品工业科技, 2019, 40(20): 82–87.LIAO H. Synergistic effects of nisin and HPP on the inactivation of Escherichia coli [J]. Science and Technology of Food Industry, 2019, 40(20): 82–87. [55] ESTACA J, CABALLERO M E, BARTOLOME M Á, et al. The effect of the combined use of high pressure treatment and antimicrobial edible film on the quality of salmon carpaccio [J]. International Journal of Food Microbiology, 2018, 283: 28–36. doi: 10.1016/j.ijfoodmicro.2018.06.015 [56] 徐永霞, 尹一鸣, 赵洪雷, 等. 肉桂醛协同超高压处理对牙鲆鱼片冷藏期间品质变化的影响 [J]. 食品科学, 2019, 40(15): 225–230. doi: 10.7506/spkx1002-6630-20180816-170XU Y X, YIN Y M, ZHAO H L, et al. Effect of cinnamaldehyde combined with ultra-high pressure treatment on the quality of Paralichthys olivaceus fillets during cold storage [J]. Food Science, 2019, 40(15): 225–230. doi: 10.7506/spkx1002-6630-20180816-170 [57] 蓝蔚青, 陈梦玲, 孙晓红, 等. 超高压结合竹醋液处理对冷藏鲈鱼片品质和蛋白特性影响 [J]. 高压物理学报, 2019, 33(1): 015301. doi: 10.11858/gywlxb.20180609LAN W Q, CHEN M L, SUN X H, et al. Effects of high hydrostatic pressure (HHP) with bamboo vinegar on the quality and protein characteristics of perch (Lateolabrax japonicus) fillets during refrigerated storage [J]. Chinese Journal of High Pressure Physics, 2019, 33(1): 015301. doi: 10.11858/gywlxb.20180609 -

下载:

下载: