| [1] |

ITO E, KATSURA T, YAMAZAKI D, et al. A new 6-axis apparatus to squeeze the Kawai-cell of sintered diamond cubes [J]. Physics of the Earth & Planetary Interiors, 2009, 174(1): 264–269.

|

| [2] |

HAN Q G, LI M Z, JIA X P, et al. Modeling of effective design of high pressure anvils used for large scale commercial production of gem quality large single crystal diamond [J]. Diamond & Related Materials, 2011, 20(7): 969–973.

|

| [3] |

YAMAZAKI D, ITO E. High pressure generation in the Kawai-type multianvil apparatus equipped with sintered diamond anvils [J]. High Pressure Research, 2020, 30(2): 78–84.

|

| [4] |

IRIFUNE T, KUNIMOTO T, SHINMEI T, et al. High pressure generation in Kawai-type multianvil apparatus using nano-polycrystalline diamond anvils [J]. Comptes Rendus, 2019, 351(2/3): 260–268.

|

| [5] |

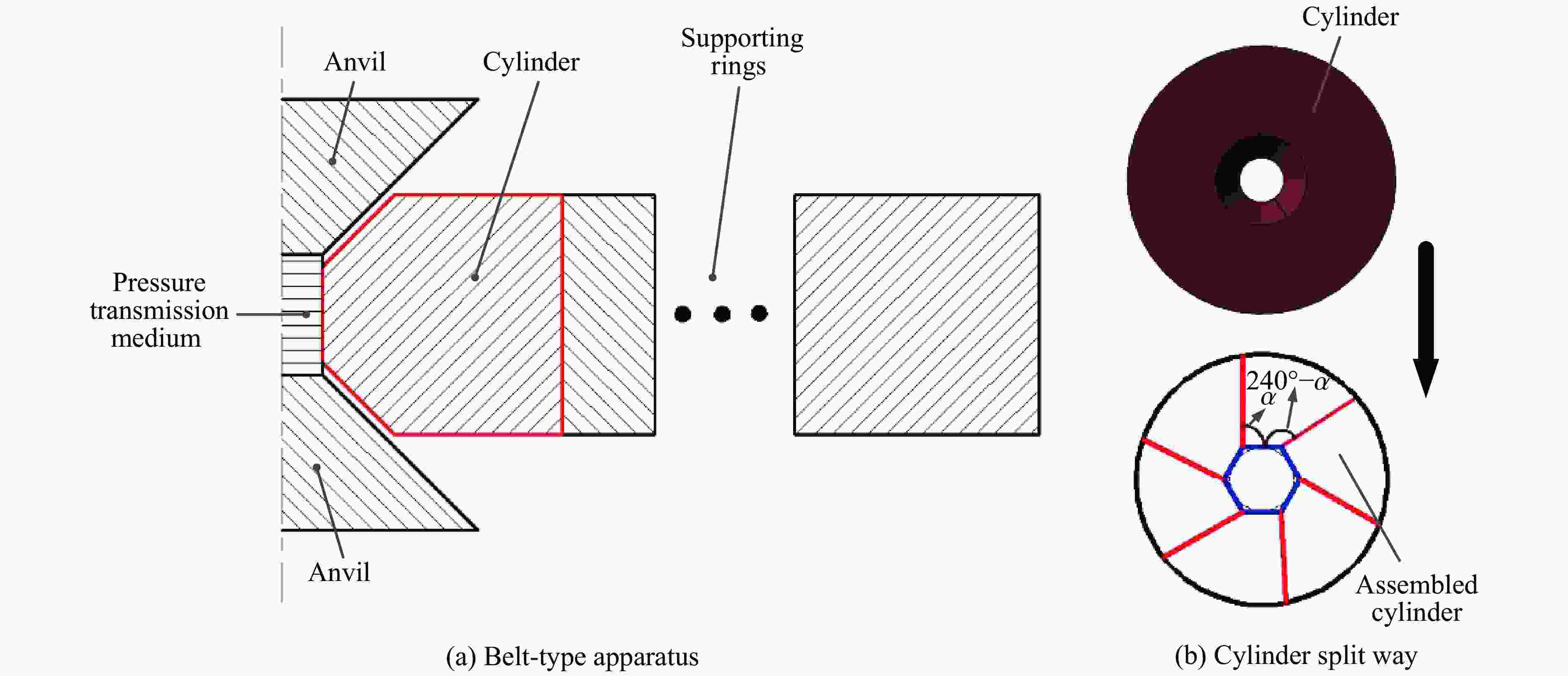

YANG Y F, LI M Z, WANG B L. Study on stress distribution of tangent split high pressure apparatus and its pressure bearing capacity [J]. Diamond & Related Materials, 2015, 58: 180–184.

|

| [6] |

王伯龙, 李明哲, 刘志卫, 等. 新型切向分块式两面顶超高压模具 [J]. 高压物理学报, 2019, 33(1): 013102.WANG B L, LI M Z, LIU Z W, et al. A novel tangential split-belt ultrahigh pressure apparatus [J]. Chinese Journal of High Pressure Physics, 2019, 33(1): 013102.

|

| [7] |

姚裕成. 人造金刚石和超高压高温技术 [M]. 北京: 化学工业出版社, 1996: 35−36.YAO Y C. Artificial diamond and ultra-high pressure and high temperature technology [M]. Beijing: Chemical Industry Press, 1996: 35−36.

|

| [8] |

ZHU B J, QU X H, TAO Y, et al. Optimization of tungsten cemented carbide injection molding process parameters [J]. Rare Metal Materials & Engineering, 2002, 31(3): 232–235.

|

| [9] |

AARON D D, WALTER J M, CHARLES E W. Machine design: theory and practice [M]. New York: Macmillan, 1975: 12−15.

|

| [10] |

GETTING I C, CHEN G, BROWN J A. The strength and rheology of commercial tungsten carbide cerments used in high-pressure apparatus, pageoph topical volumes [J]. Pure & Applied Geophysics, 1993, 141(2/3/4): 545–577.

|

| [11] |

WANG B L, LI M Z, YANG Y F, et al. Numerical simulation of multilayer stagger-split die and experiment on the bearing capacity [J]. High Pressure Research, 2015, 35(4): 388–395. doi: 10.1080/08957959.2015.1073273

|

| [12] |

YANG Y F, LI M Z, LIU Z W, et al. Numerical simulation and experiment on split tungsten carbide cylinder of high pressure apparatus [J]. Review of Scientific Instruments, 2015, 86(12): 125113. doi: 10.1063/1.4939033

|

| [13] |

VRBKA J, KNESL Z. Proceedings of high pressure geoscience and material synthesis [M]. Berlin: Akademie-Verlag, 1988: 234.

|

| [14] |

ZHAO L, LI M Z, WANG L Y, et al. Stress distribution and pressure-bearing capacity of a high-pressure split-cylinder die with prism cavity [J]. Review of Scientific Instruments, 2018, 89(3): 035106. doi: 10.1063/1.5026407

|

| [15] |

KLUNSNER T, WURSTER S, SUPANCIC P, et al. Effect of specimen size on the tensile strength of WC-Co hard metal [J]. Acta Materialia, 2011, 59(10): 4244–4252. doi: 10.1016/j.actamat.2011.03.049

|

下载:

下载: