Process of Improved Hot Mandrel for Large Length-Diameter Ratio Warhead Melting Cast

-

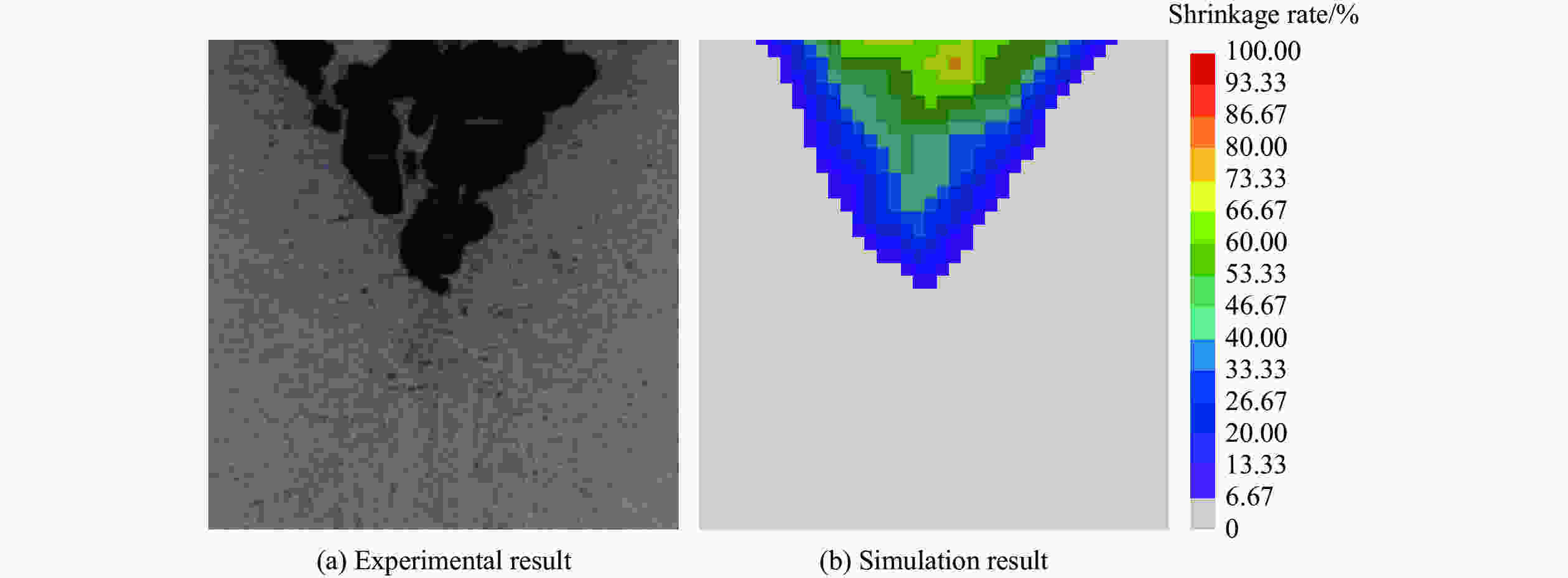

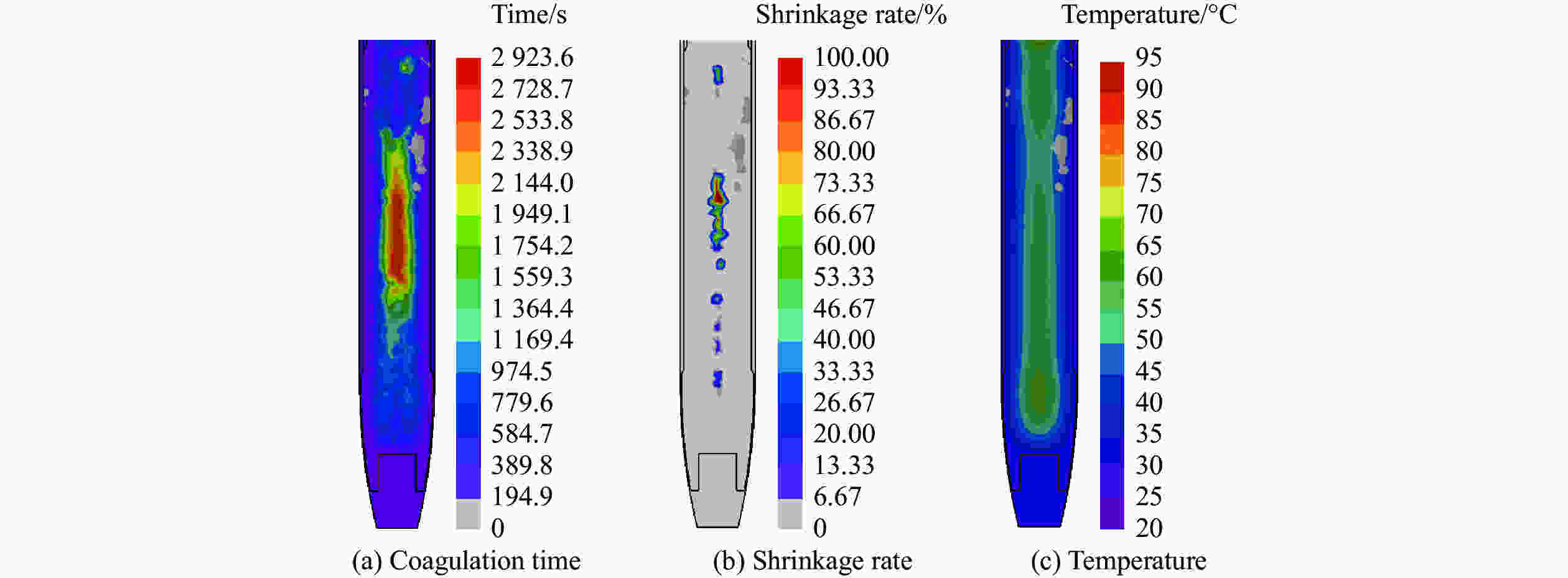

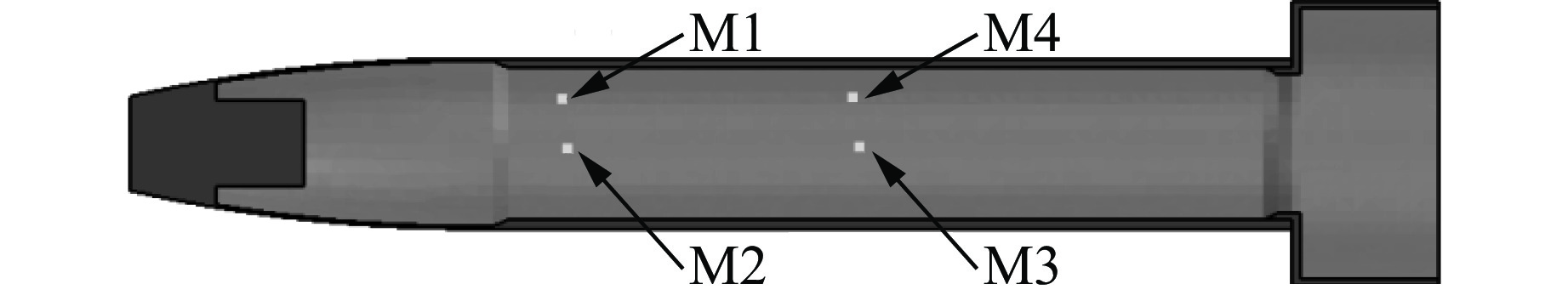

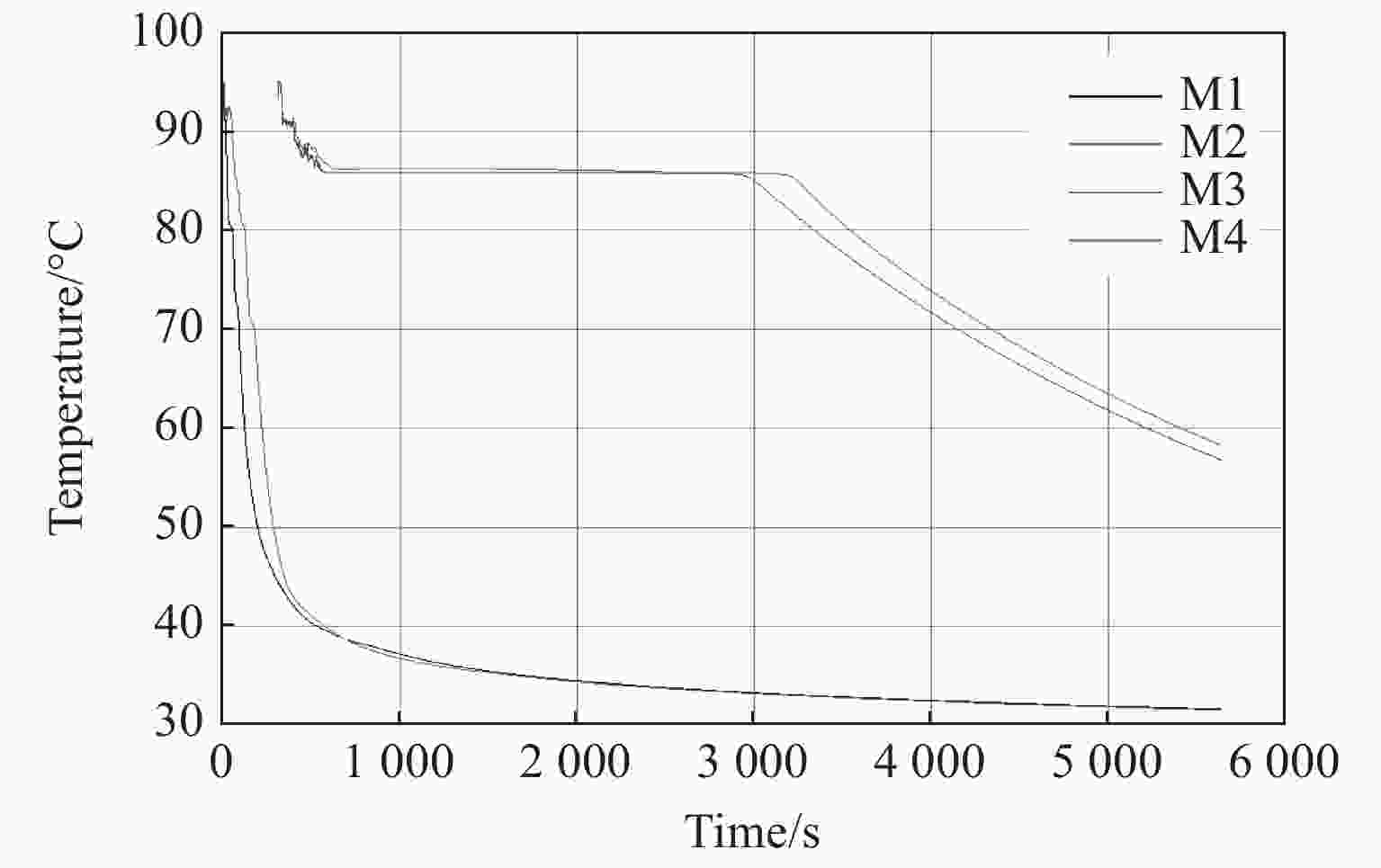

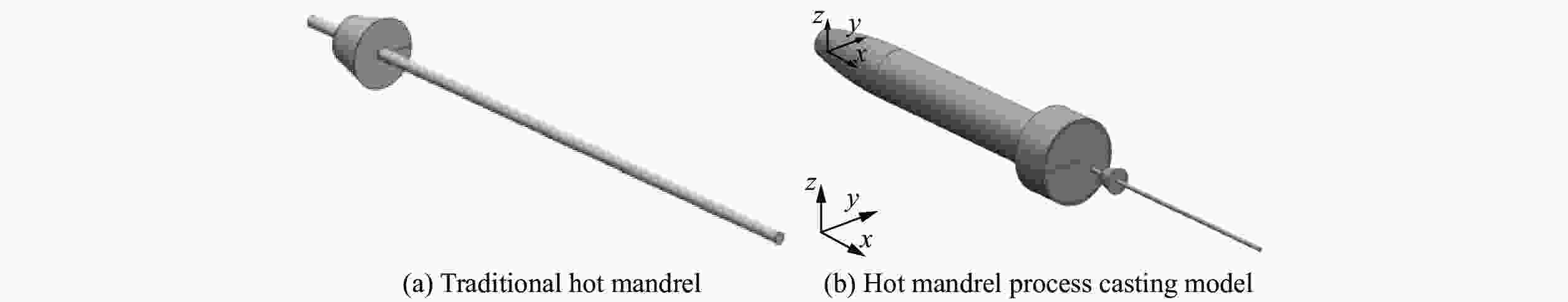

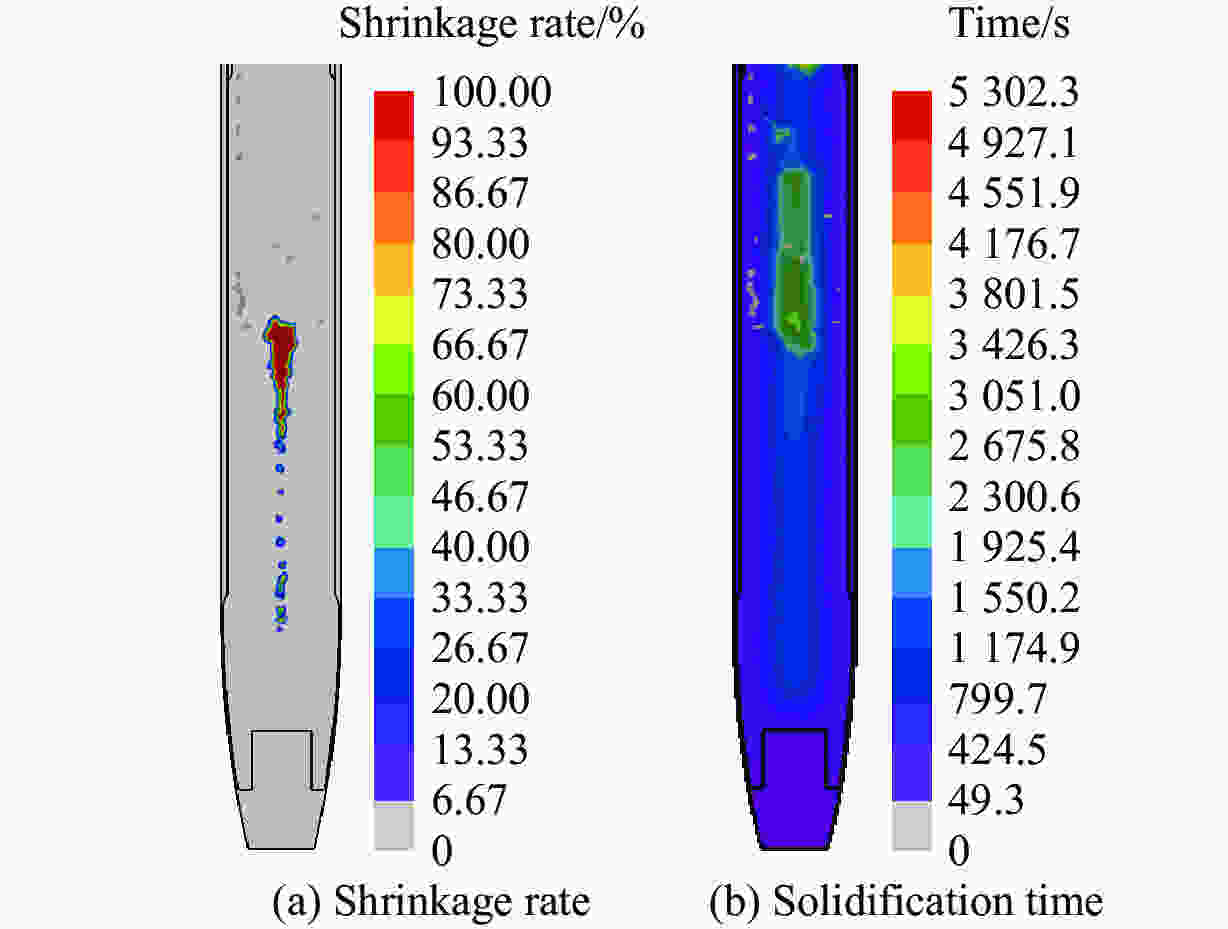

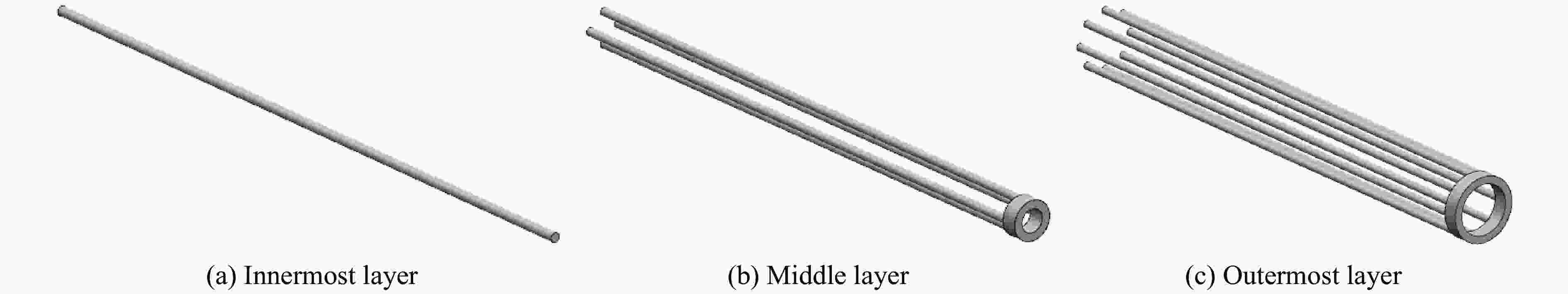

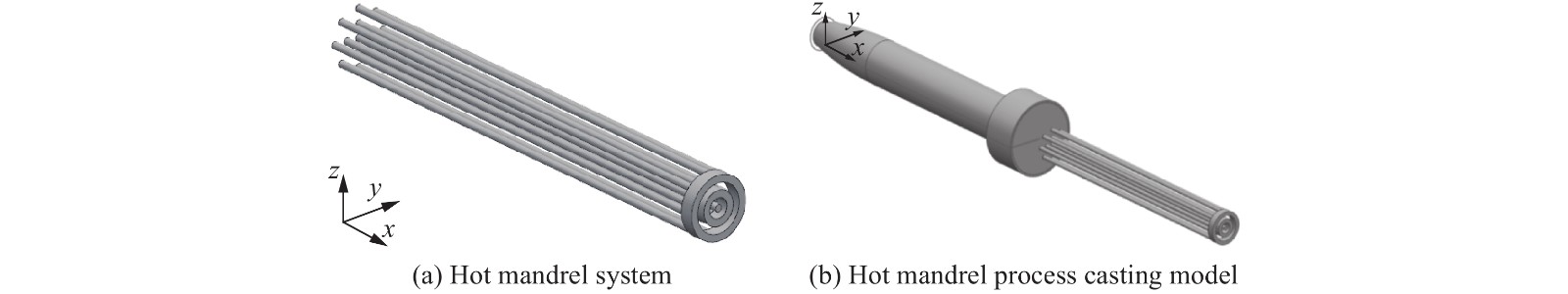

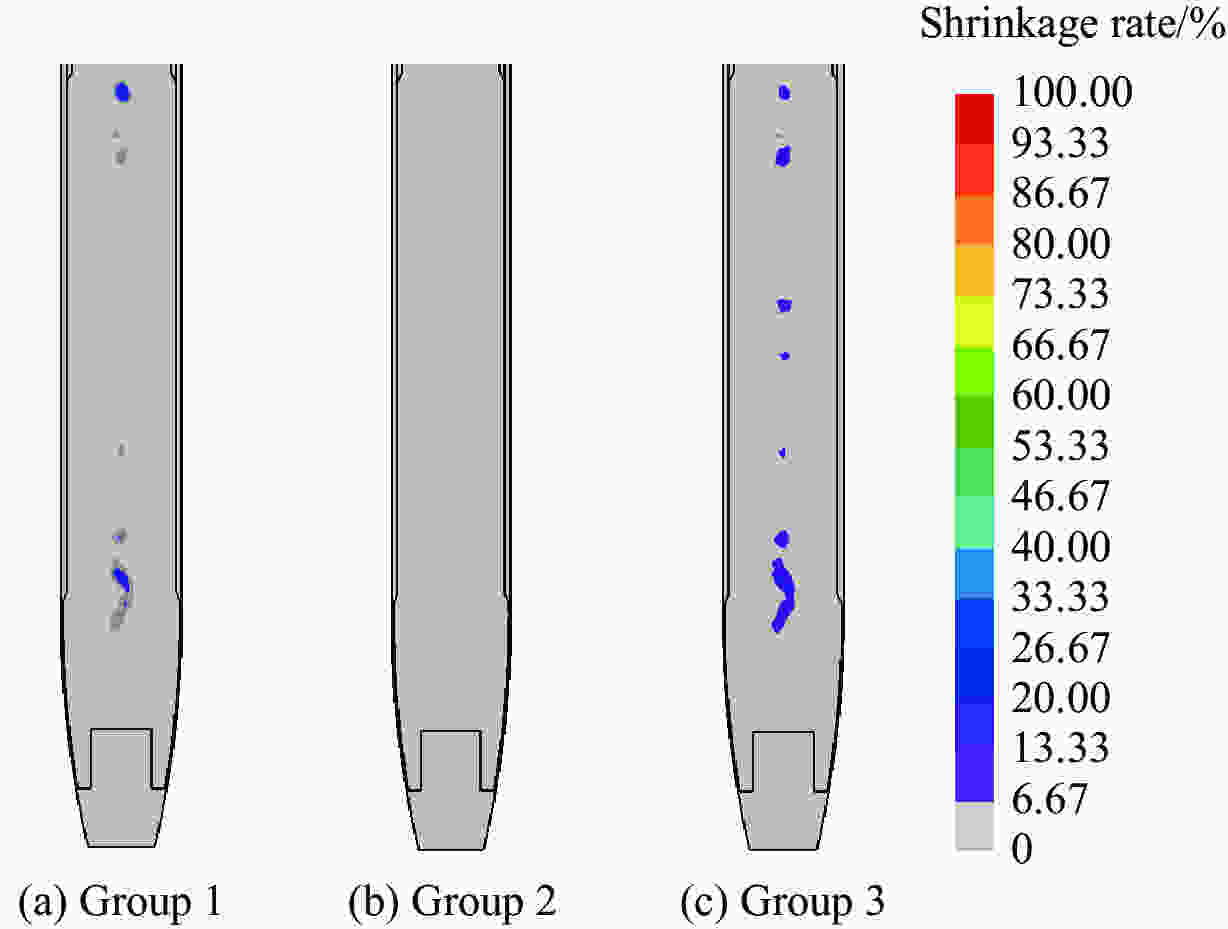

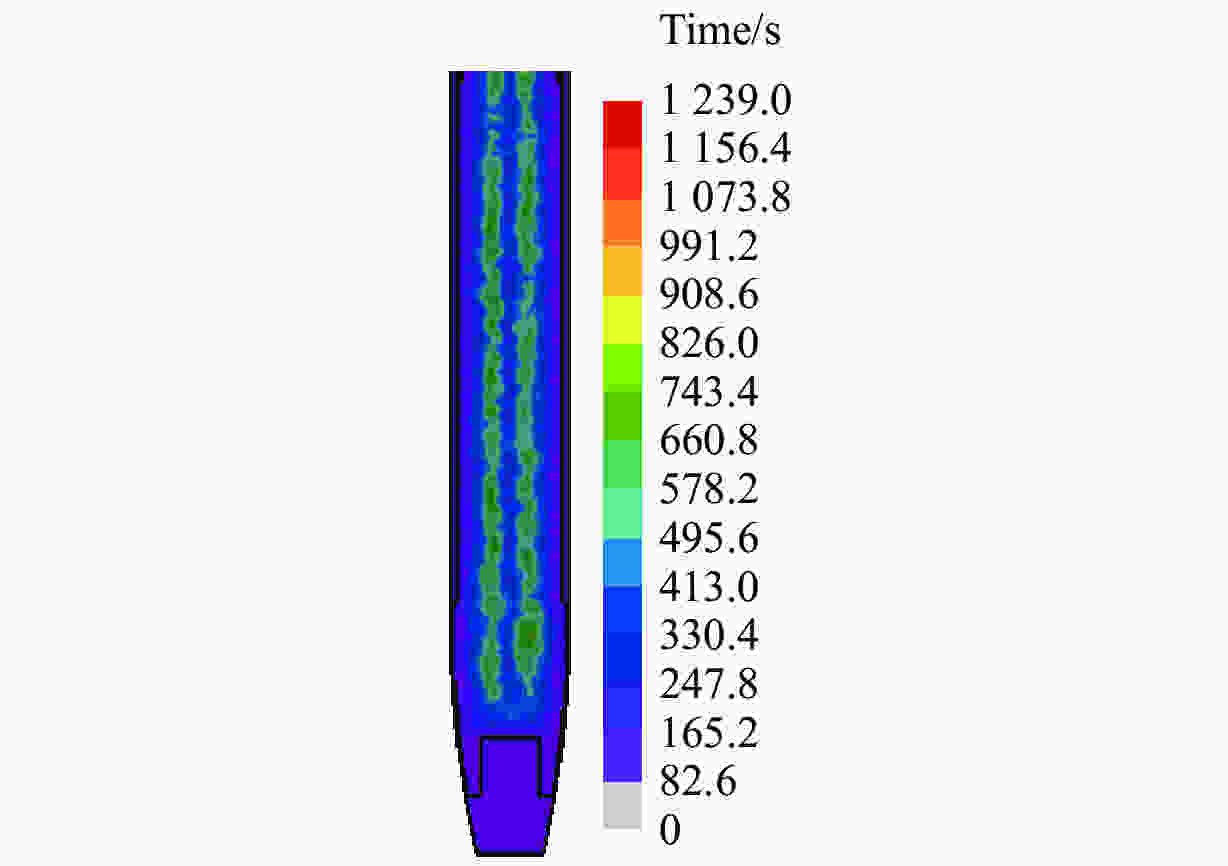

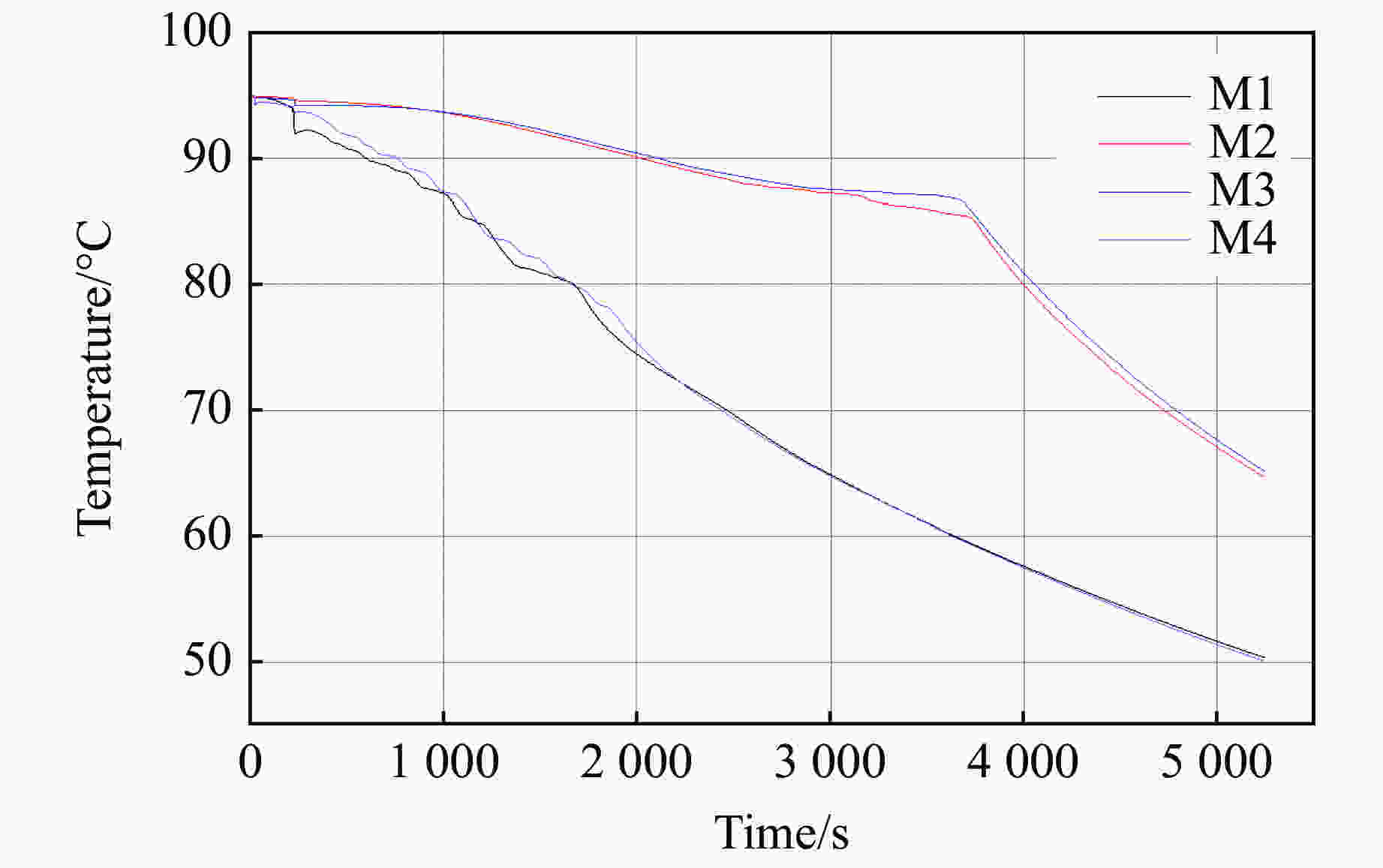

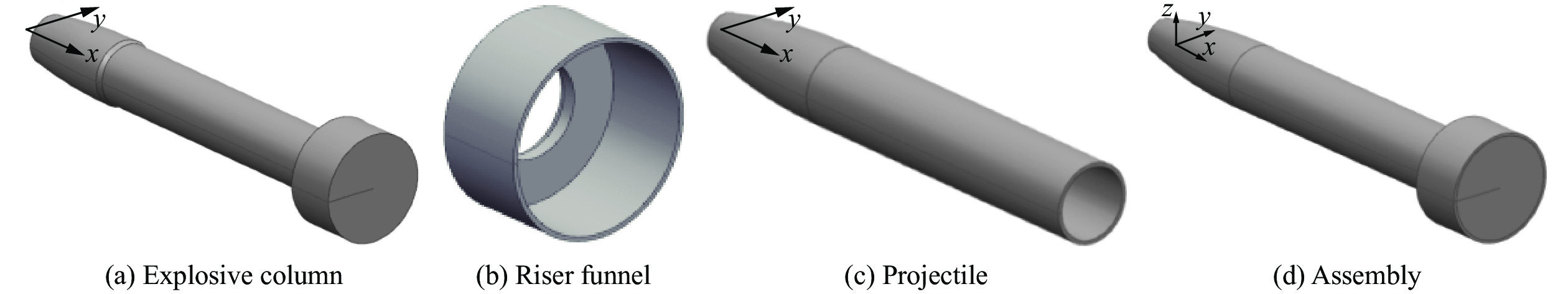

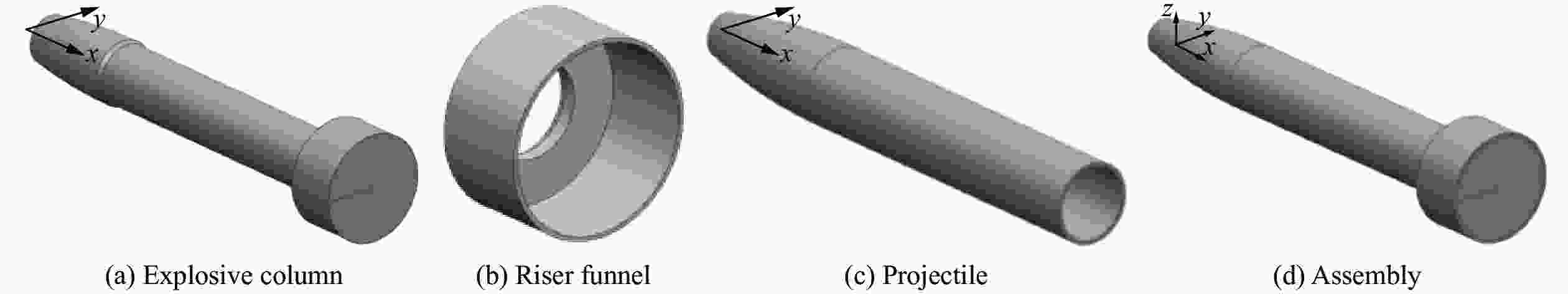

摘要: 为提高大长径比战斗部的熔铸装药质量,采用有限元仿真方法建立了三维装药模型,对熔铸装药过程进行数值模拟。通过分析传统铸装和热芯棒工艺铸装的仿真结果,结合缩孔形成原因和传统热芯棒工艺对装药质量的改善机理,设计出一种多层次优化温度控制的热芯棒,并对改良热芯棒工艺铸装过程进行数值模拟,预测热芯棒改良工艺对装药质量的影响。结果表明:传统热芯棒铸装工艺无法改变药柱径向凝固顺序,在药室宽大处仍然会出现缩孔缩松的疵病,而改良热芯棒工艺通过改善药柱凝固顺序,可以预防缩孔缩松出现,达到了预期要求。Abstract: In order to improve melt-casting charge quality of the warhead with a large length-diameter ratio, a three-dimensional charge model was established by means of the finite element simulation method, and numerical simulation on the melt-casting charge process was carried out, including traditional casting and hot mandrel process casting. Then combined with the shrinkage principle and mechanism of the traditional hot mandrel process to improve charge quality, a multi-layered hot mandrel with optimized temperature controlling was proposed and its casting process simulation was undertaken to predict how it exerts effects on the charge quality. The results show that the radial solidification order of the grains can’t be changed and shrinkage as well as porosity would appear at the wider area of the explosive room in the traditional hot mandrel casting process. However, the defects of shrinkage and porosity can be avoided by changing the radial solidification order in the improved hot mandrel process, which just corresponds to our expectation.

-

Key words:

- melt-casting charge /

- shrinkage and porosity /

- hot mandrel /

- solidification process

-

Material $\theta\rm{_m} $/℃ L/(kJ·kg–1) C/(J·kg–1·K–1) $\,\rho $/(g·cm–3) $\,\mu$/(Pa·s) $\alpha $/K–1 Explosive B 78–80 33.5 1 063 (25 ℃)

1 276 (50 ℃)

1 573 (75 ℃)

1 481 (85 ℃)

1 427 (90 ℃)

1 035 (100 ℃)1.680 0.31 (83 ℃)

0.27 (90 ℃)

0.27 (95 ℃)7.69 × 10–5 (23 ℃)

2.00 × 10–5 (50 ℃)

5.00 × 10–6 (75 ℃)

1.00 × 10–6 (80 ℃)H13 steel 0.73 7.800 4.45 × 10–8 (22–500 ℃) Al 0.90 7.625 表 2 热芯棒位移-时间关系

Table 2. Displacement-time relationship of the hot mandrel

t/s x/mm 0 0 5 600 500 600 1 000 0 -

[1] 郑保辉, 罗观, 舒远杰, 等. 熔铸炸药研究现状与发展趋势 [J]. 化工进展, 2013, 32(6): 1341–1346.ZHENG B H, LUO G, SHU Y J, et al. Research status and prospect of melt-cast explosive [J]. Chemical Industry and Engineering Progress, 2013, 32(6): 1341–1346. [2] 智小琦. 弹箭炸药装药技术[M]. 北京: 兵器工业出版社, 2011: 79–80.ZHI X Q. Ammunition charging technology for ammunition [M]. Beijing: Ordnance Industry Press, 2011: 79–80. [3] 张恒志. 火炸药应用技术[M]. 北京: 北京理工大学出版社, 2010: 65–82.ZHANG H Z. Application technology of explosives [M]. Beijing: Beijing Institute of Technology Press, 2010: 65–82. [4] ZHU D L, ZHOU L, ZHANG X R. Rheological behavior of DNAN/HMX melt-cast explosives [J]. Propellants, Explosives, Pyrotechnics, 2019, 44(12): 1583–1589. doi: 10.1002/prep.201900117 [5] SANHYE W, DUBOIS C, LAROCHE I, et al. Numerical modeling of the cooling cycle and associated thermal stresses in a melt explosive charge [J]. AIChE Journal, 2016, 62(10): 3797–3811. doi: 10.1002/aic.15288 [6] 刘威, 曹红松. 基于灰色理论的DNAN基熔铸炸药成型工艺参数优化 [J]. 机械工程师, 2016, 3(3): 58–60. doi: 10.3969/j.issn.1002-2333.2016.03.024LIU W, CAO H S. Parameters optimization in DANA-based melt-cast explosive based on grey theory [J]. Mechanical Engineer, 2016, 3(3): 58–60. doi: 10.3969/j.issn.1002-2333.2016.03.024 [7] 王政, 芮久后, 赵雪, 等. DNAN基高致密熔铸炸药装药安全性研究 [J]. 广东化工, 2015, 42(24): 6–7, 24. doi: 10.3969/j.issn.1007-1865.2015.24.003WANG Z, RUI J H, ZHAO X, et al. The safety analysis of high density melt-casting explosive based on DNAN [J]. Guangdong Chemical Industry, 2015, 42(24): 6–7, 24. doi: 10.3969/j.issn.1007-1865.2015.24.003 [8] 王宇, 芮久后, 冯顺山. 装药缺陷对熔铸炸药爆速影响的实验研究 [J]. 北京理工大学学报, 2011, 31(7): 757–761.WANG Y, RUI J H, FENG S S. Experimental research of the charge defects’ influence on detonation velocity of melting-cast explosive [J]. Transactions of Beijing Institute of Technology, 2011, 31(7): 757–761. [9] 冀腾宇. DNAN基熔铸炸药装药发射安全性研究[D]. 北京: 北京理工大学, 2016.JI T Y. Research on DNAN based melt-cast explosive charge and launching safety [D]. Beijing: Beijing Institute of Technology, 2016. [10] WANG D L, XIE Z Y, SUN W X, et al. Solidification simulation of melt-cast explosive under pressurization [J]. Material Science Forum, 2011, 704/705(1): 71–75. [11] 李敬明, 田勇, 张伟斌, 等. 炸药熔铸过程缩孔和缩松的形成与预测 [J]. 火炸药学报, 2011, 34(2): 17–20. doi: 10.3969/j.issn.1007-7812.2011.02.004LI J M, TIAN Y, ZHANG W B, et al. Formation and prediction of shrinkage hole and shrinkage porosity in explosive during casting process [J]. Chinese Journal of Explosives & Propellants, 2011, 34(2): 17–20. doi: 10.3969/j.issn.1007-7812.2011.02.004 [12] 黄勇, 郑保辉, 谢志毅, 等. 熔铸炸药加压凝固过程研究 [J]. 含能材料, 2013, 21(1): 25–29. doi: 10.3969/j.issn.1006-9941.2013.01.006HUANG Y, ZHENG B H, XIE Z Y, et al. Pressured solidification process of melt-cast explosive [J]. Chinese Journal of Energetic Materials, 2013, 21(1): 25–29. doi: 10.3969/j.issn.1006-9941.2013.01.006 [13] 田勇. 炸药熔铸成型过程监测评价及数值模拟研究[D]. 北京: 中国科学院工程热物理研究所, 2010.TIAN Y. Process monitoring/evaluation and numerical simulation during casting explosive solidification [D]. Beijing: Institute of Engineering Thermophysics, Chinese Academy of Sciences, 2010. [14] 蒙君煚, 张向荣, 周霖, 等. DNAN基熔铸炸药成型过程数值仿真 [J]. 兵工学报, 2013, 34(7): 810–814.MENG J J, ZHANG X R, ZHOU L, et al. Simulation of solidification process for DNAN-based melt-cast explosives [J]. Acta Armamentarii, 2013, 34(7): 810–814. [15] SUN D W, GARIMELLA S V, SINGH S, et al. Numerical and experimental investigation of the melt casting of explosives [J]. Propellants, Explosives, Pyrotechnics, 2018, 30(5): 369–380. [16] 张川, 余瑾. 基于ProCAST的124D型主泵泵壳铸造工艺设计及优化 [J]. 大型铸锻件, 2019, 10(1): 14–17.ZHANG C, YU J. Casting process design and optimization of 124D main pump casing based on ProCAST [J]. Heavy Casting Forging, 2019, 10(1): 14–17. [17] 易茂光, 张明明, 冉靖, 等. 弹药熔铸装药水浴护理凝固控制技术 [J]. 兵工自动化, 2019, 38(8): 14–17.YI M G, ZHANG M M, RAN J. Solidification control technology of melt-casting charging under water bath curing [J]. Ordnance Industry Automation, 2019, 38(8): 14–17. [18] 钟一鹏, 胡雅达, 江宏志. 国外炸药性能手册[M]. 北京: 兵器工业出版社, 1990: 117–118.ZHONG Y P, HU Y D, JIANG H Z. Foreign explosive performance manual [M]. Beijing: Ordnance Industry Press, 1990: 117–118. [19] 苗爽, 王涛, 王玉玲. 孔洞缺陷对B炸药性能影响的理论计算 [J]. 原子与分子物理学报, 2019, 36(4): 675–681. doi: 10.3969/j.issn.1000-0364.2019.04.023MIAO S, WANG T, WANG Y L. Theoretical calculation on effects of void defects on properties of composition B [J]. Journal of Atomic and Molecular Physics, 2019, 36(4): 675–681. doi: 10.3969/j.issn.1000-0364.2019.04.023 [20] 谭彦显, 杨伟峰, 徐立华, 等. 模具材料及表面强化处理[M]. 2版. 北京: 北京理工大学出版社, 2014: 197–198.TAN Y X, YANG W F, XU L H, et al. Mold material and surface strengthening treatment [M]. 2nd ed. Beijing: Beijing Institute of Technology Press, 2014: 197–198. [21] 刘雨荻. 凝固工艺对熔铸炸药微观结晶组织的影响研究[D]. 太原: 中北大学, 2019.LIU Y D. Research on the effect of solidification process on the crystalline structure of melt-cast explosive [D]. Taiyuan: North University of China, 2019. -

下载:

下载: