| [1] |

江洁, 董侠, 陈美玉, 等. 现代防弹材料 [J]. 材料导报, 2013, 27(6): 70–76.JIANG J, DONG X, CHEN M Y, et al. A review of modern bulletproof materials [J]. Materials Reports, 2013, 27(6): 70–76.

|

| [2] |

孙志杰, 吴燕, 张佐光, 等. 防弹陶瓷的研究现状与发展趋势 [J]. 宇航材料工艺, 2005(5): 10–14. doi: 10.3969/j.issn.1007-2330.2005.02.003SUN Z J, WU Y, ZHANG Z G, et al. Current status and development of ballistic ceramics [J]. Aerospace Materials & Technology, 2005(5): 10–14. doi: 10.3969/j.issn.1007-2330.2005.02.003

|

| [3] |

王振兴, 原梅妮, 李立州, 等. 贝壳珍珠母增韧机理研究进展 [J]. 材料导报, 2015, 29(8): 98–102.WANG Z X, YUAN M N, LI L Z, et al. Research progress of toughening mechanisms of nacre shell [J]. Materials Reports, 2015, 29(8): 98–102.

|

| [4] |

GRUJICIC M, SNIPES J S, RAMASWAMI S. Ballistic impact behavior of nacre-like laminated composites consisting of B4C tablets and polyurea matrix [J]. Journal of Materials Engineering & Performance, 2016, 25(3): 977–994.

|

| [5] |

GRUJICIC M, RAMASWAMI S, SNIPES J. Computational investigation of ballistic-impact behavior and penetration resistance of a nacre-like ceramic/polymer laminated composite [J]. International Journal of Structural Integrity, 2017, 8(1): 79–107. doi: 10.1108/IJSI-09-2015-0041

|

| [6] |

WU K J, ZHENG Z J, ZHANG S S, et al. Interfacial strength-controlled energy dissipation mechanism and optimization in impact-resistant nacreous structure [J]. Materials & Design, 2019, 163: 107532.

|

| [7] |

WANG Z G, SUN Y Y, WU H, et al. Low velocity impact resistance of bio-inspired building ceramic composites with nacre-like structure [J]. Construction and Building Materials, 2018, 169: 851–858. doi: 10.1016/j.conbuildmat.2018.03.043

|

| [8] |

GU G X, TAKAFFOLI M, HSIEH A J, et al. Biomimetic additive manufactured polymer composites for improved impact resistance [J]. Extreme Mechanics Letters, 2016, 9: 317–323. doi: 10.1016/j.eml.2016.09.006

|

| [9] |

FLORES-JOHNSON E A, SHEN L M, GUIAMATSIA I, et al. A numerical study of bioinspired nacre-like composite plates under blast loading [J]. Composite Structures, 2015, 126: 329–336. doi: 10.1016/j.compstruct.2015.02.083

|

| [10] |

HAYNES A, REINHARDT L, LIM C. Design and processing of alumina plate composites for ballistic nacre alumina structures [J]. Processing and Manufacturing, 2018, 3(18): 957–962.

|

| [11] |

YIN Z, HANNARD F, BARTHELAT F. Impact-resistant nacre-like transparent materials [J]. Science, 2019, 364(6447): 1260–1263. doi: 10.1126/science.aaw8988

|

| [12] |

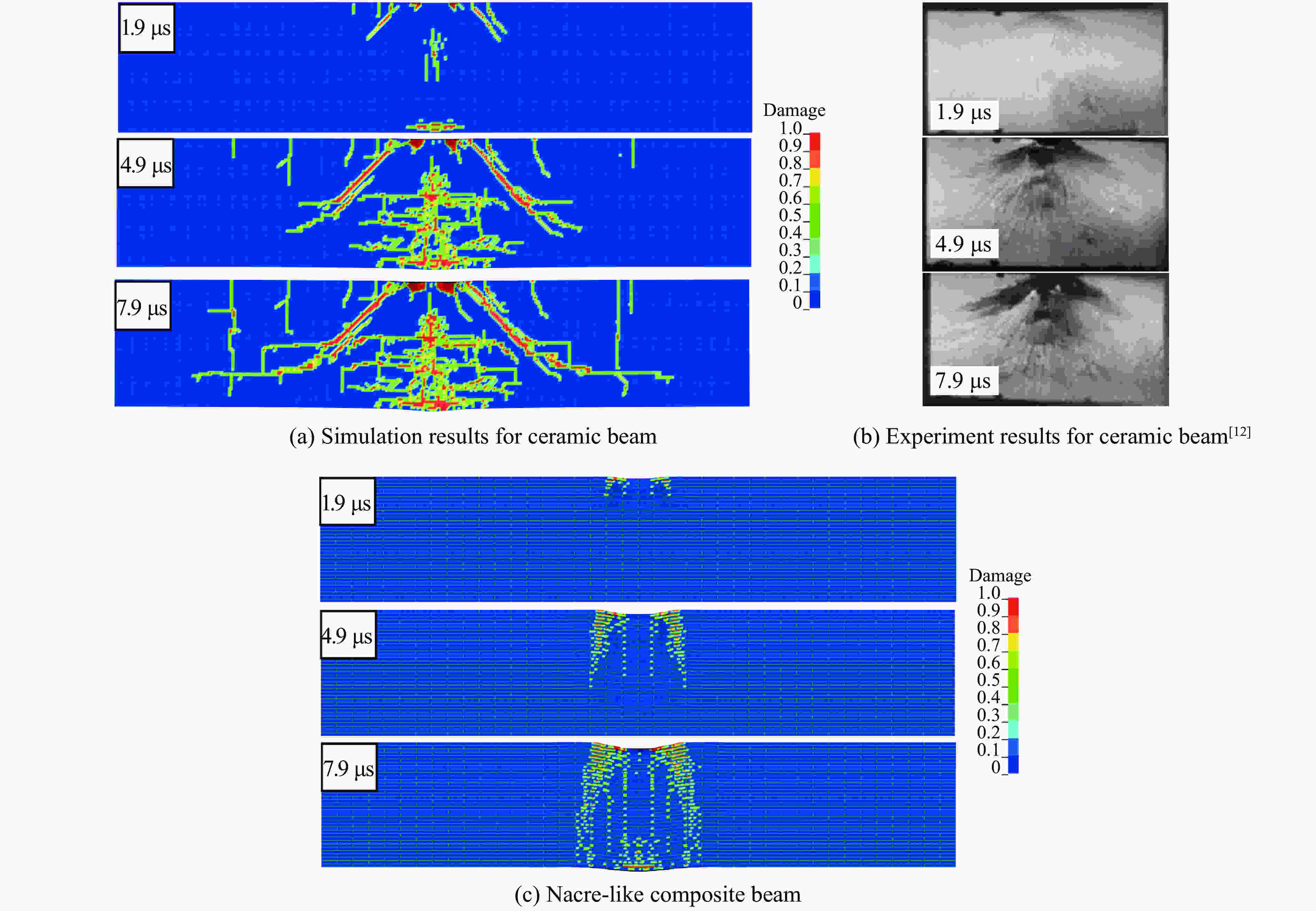

RIOU P, DENOUAL C, COTTENOT C E. Visualization of the damage evolution in impacted silicon carbide ceramics [J]. International Journal of Impact Engineering, 1998, 21(4): 225–235. doi: 10.1016/S0734-743X(97)00018-3

|

| [13] |

JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures [C]//7th International Symposium on Ballistics. Hague, Netherlands, 1983: 541–547.

|

| [14] |

CRONIN D S, BUI K, KAUFMANN C, et al. Implementation and validation of the Johnson-Holmquist ceramic material model in LS-DYNA [C]//4th European LS-DYNA Users Conference. Ulm, Germany, 2004: 47–60.

|

| [15] |

MOHOTTI D, ALI M, NGO T, et al. Strain rate dependent constitutive model for predicting the material behaviour of polyurea under high strain rate tensile loading [J]. Materials & Design, 2014, 53: 830–837.

|

下载:

下载: