Fragmentation Process of Quartz Glass Spheres Impacting Rigid Wall

-

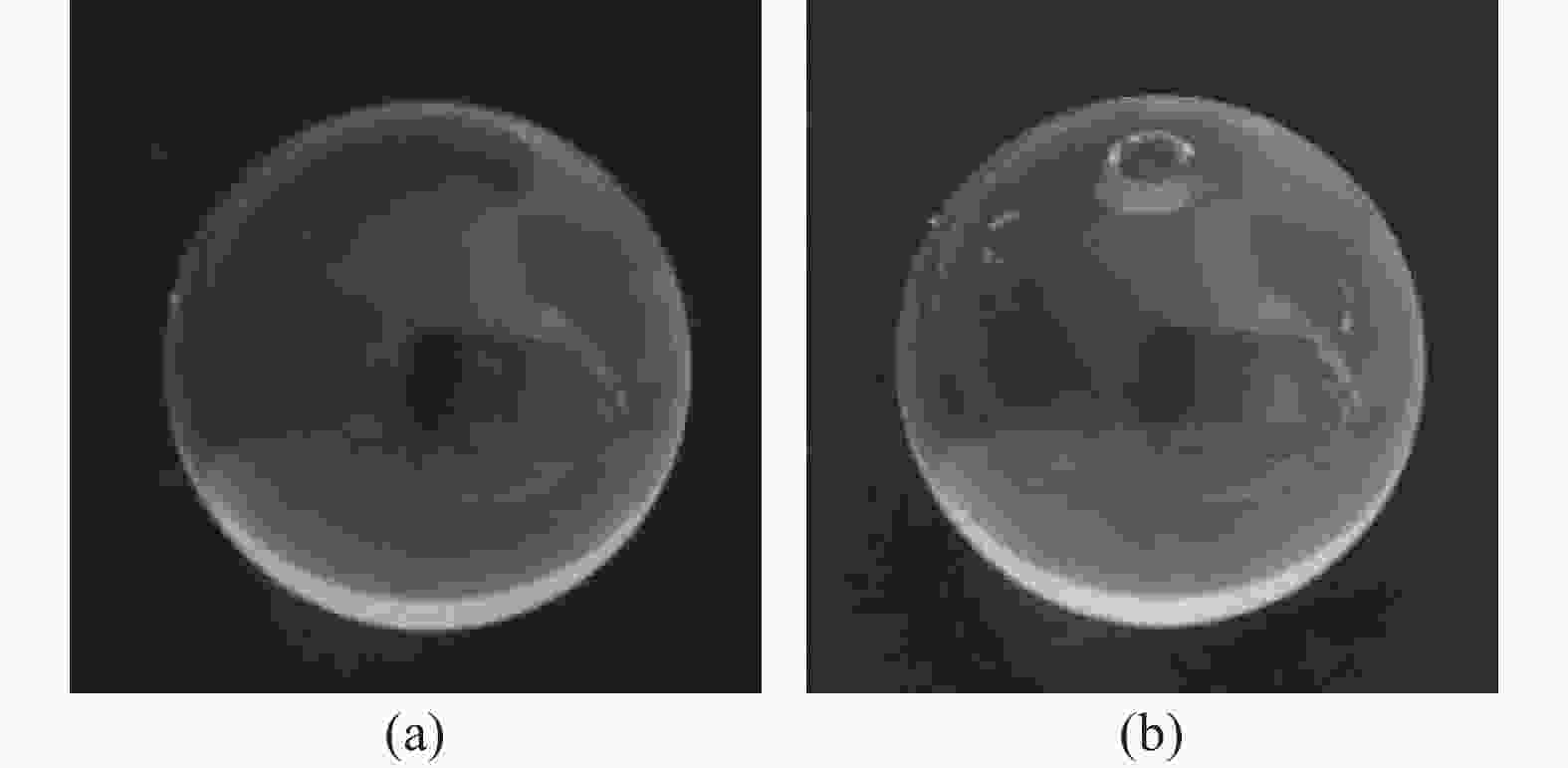

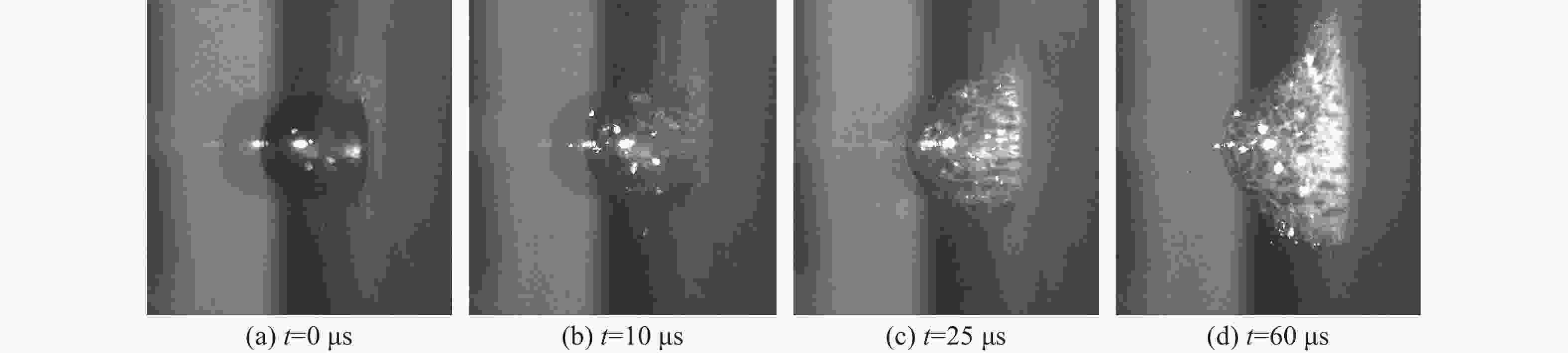

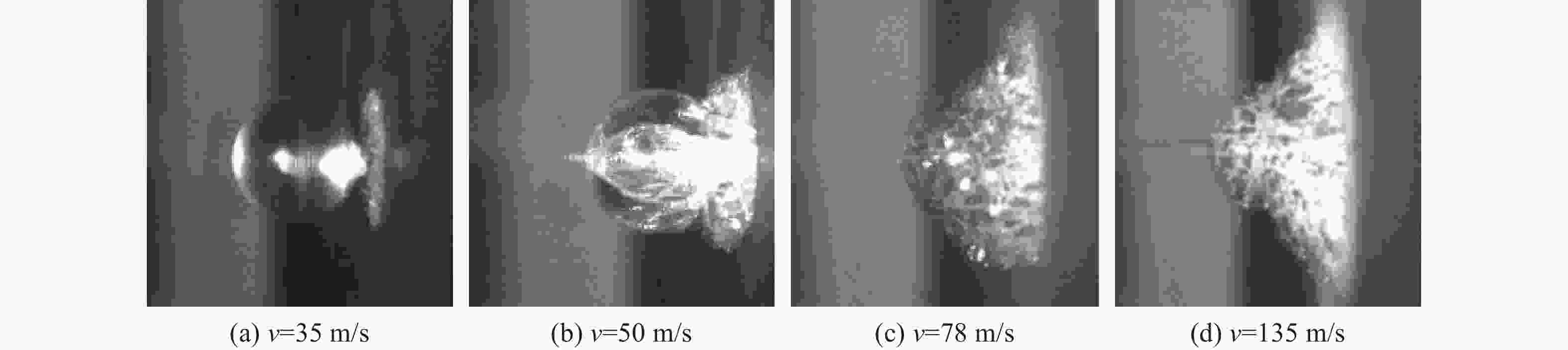

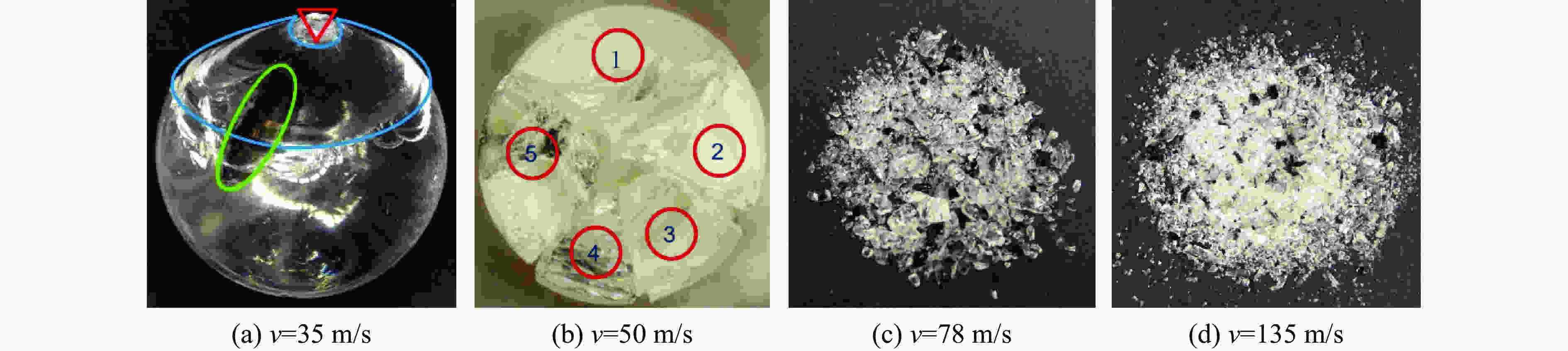

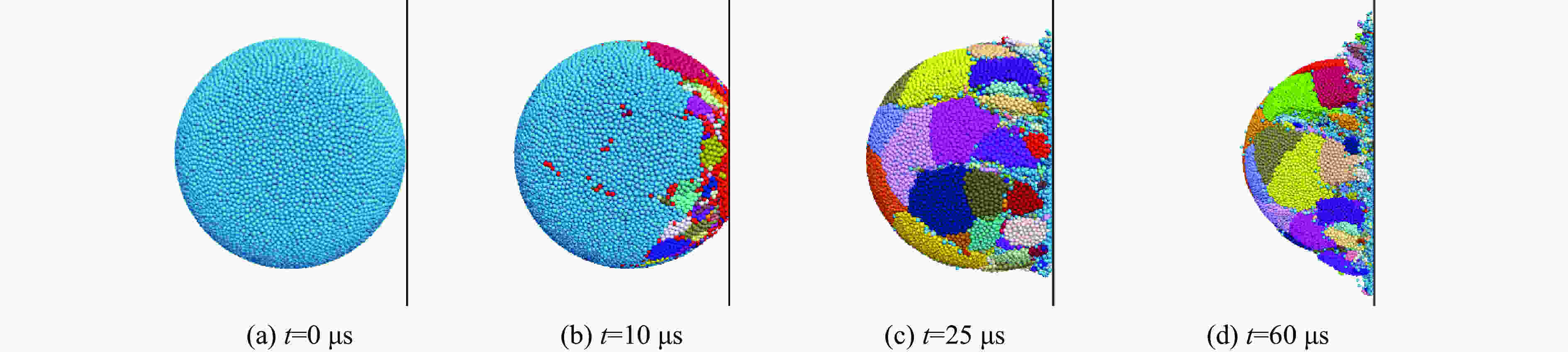

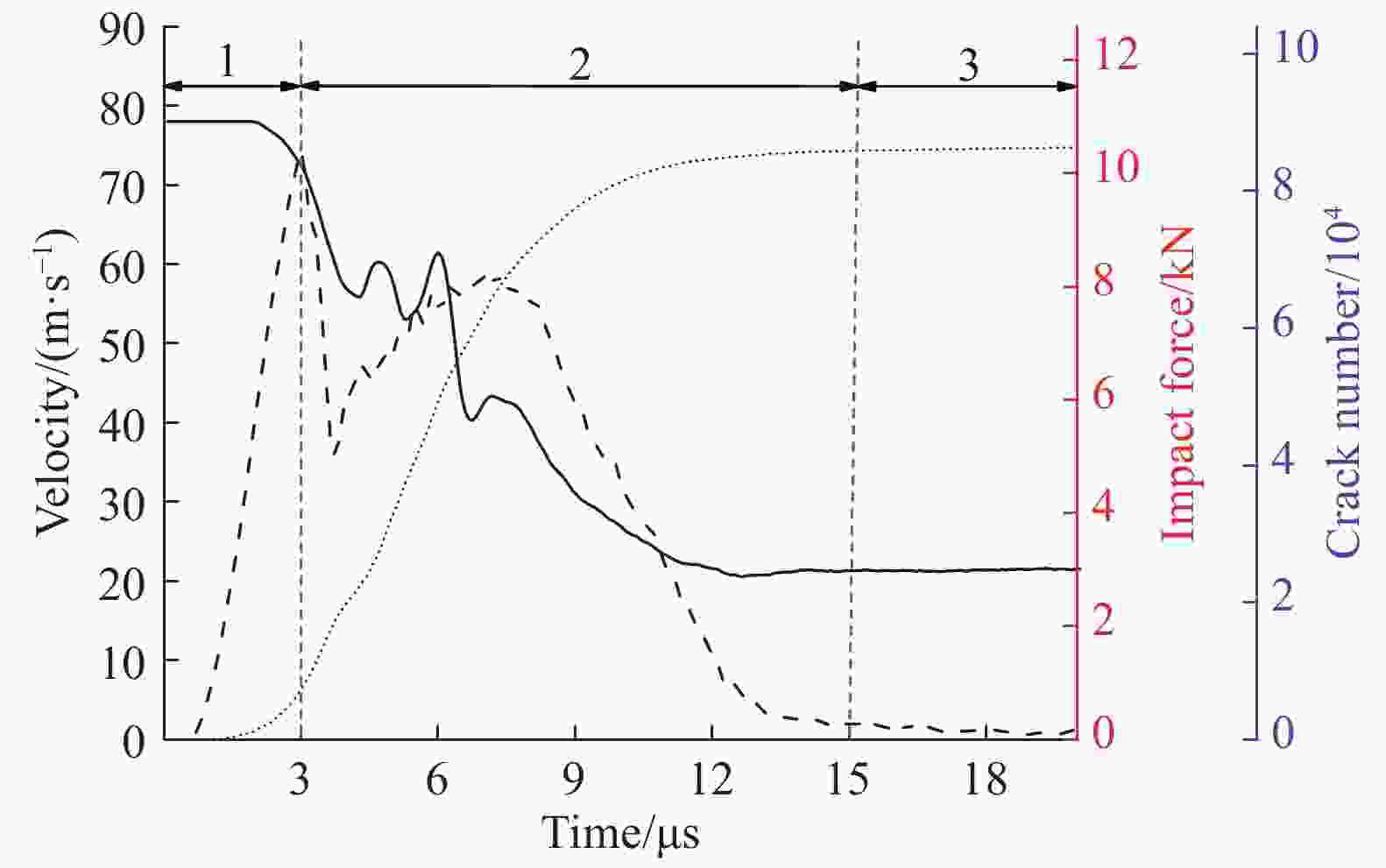

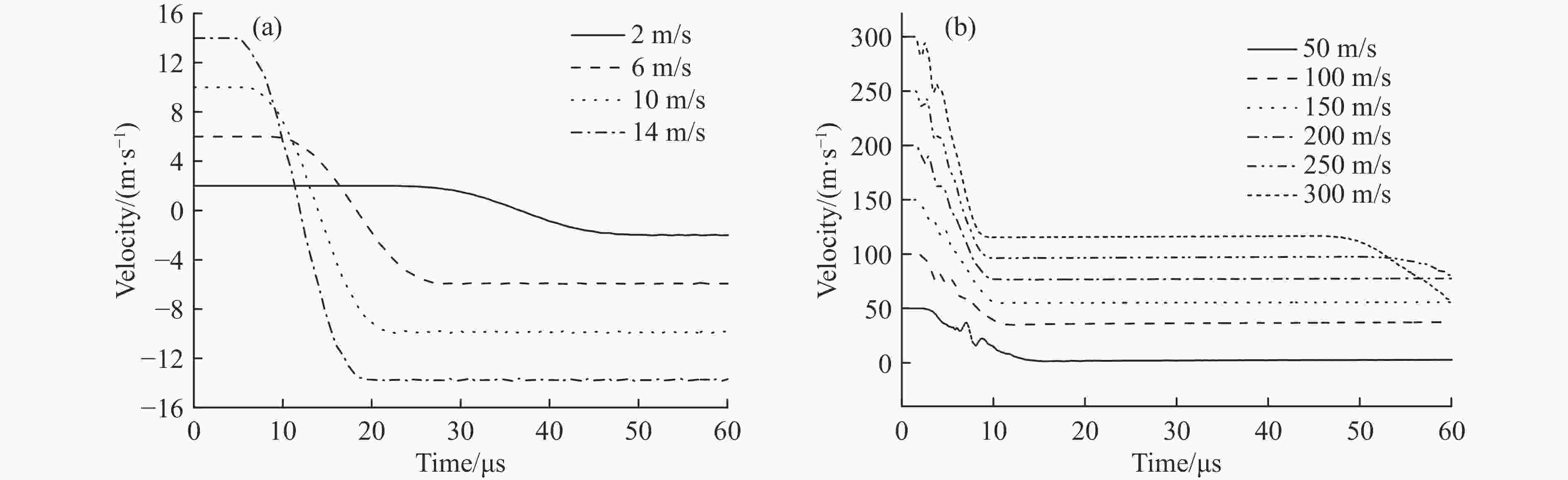

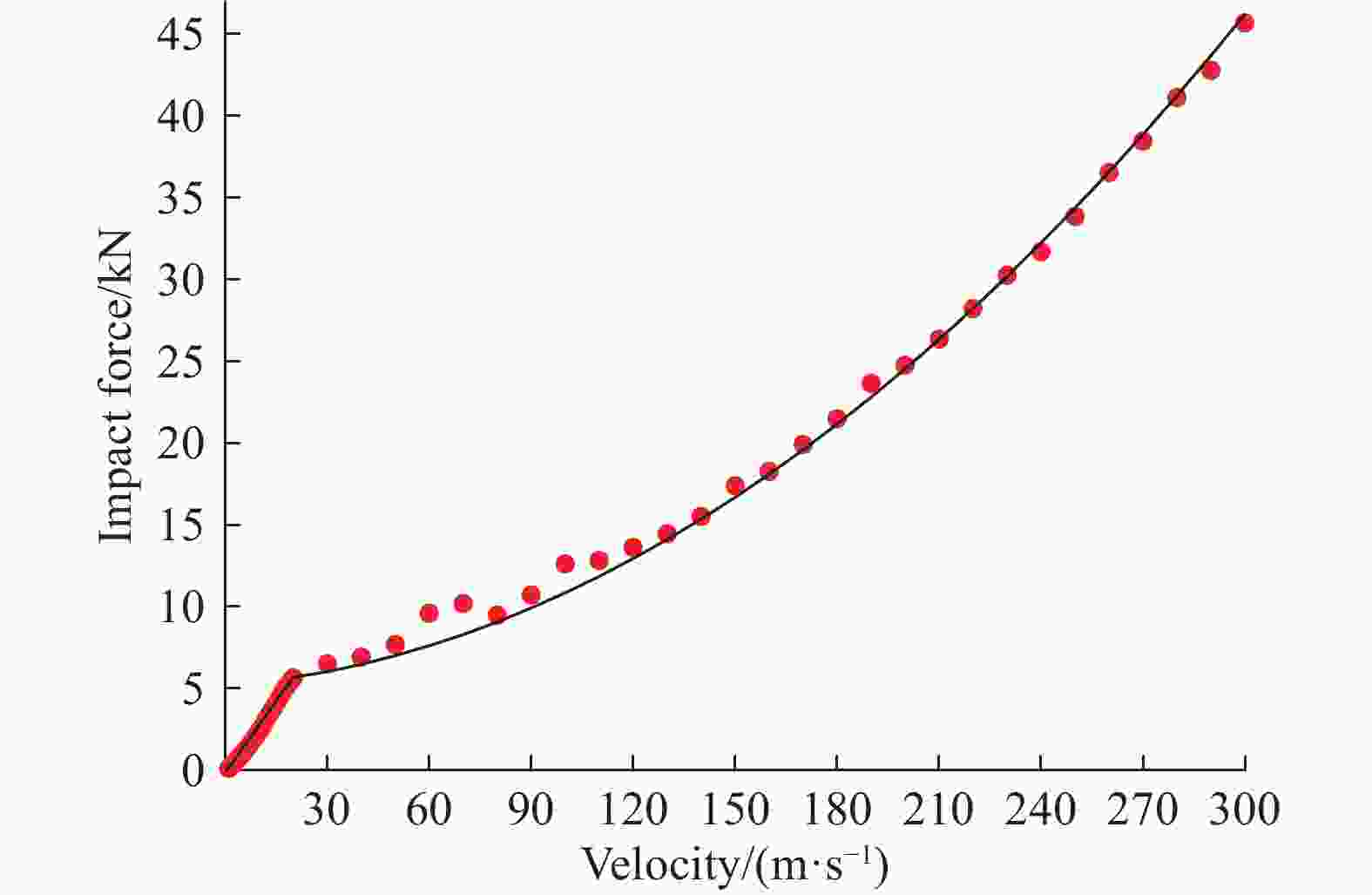

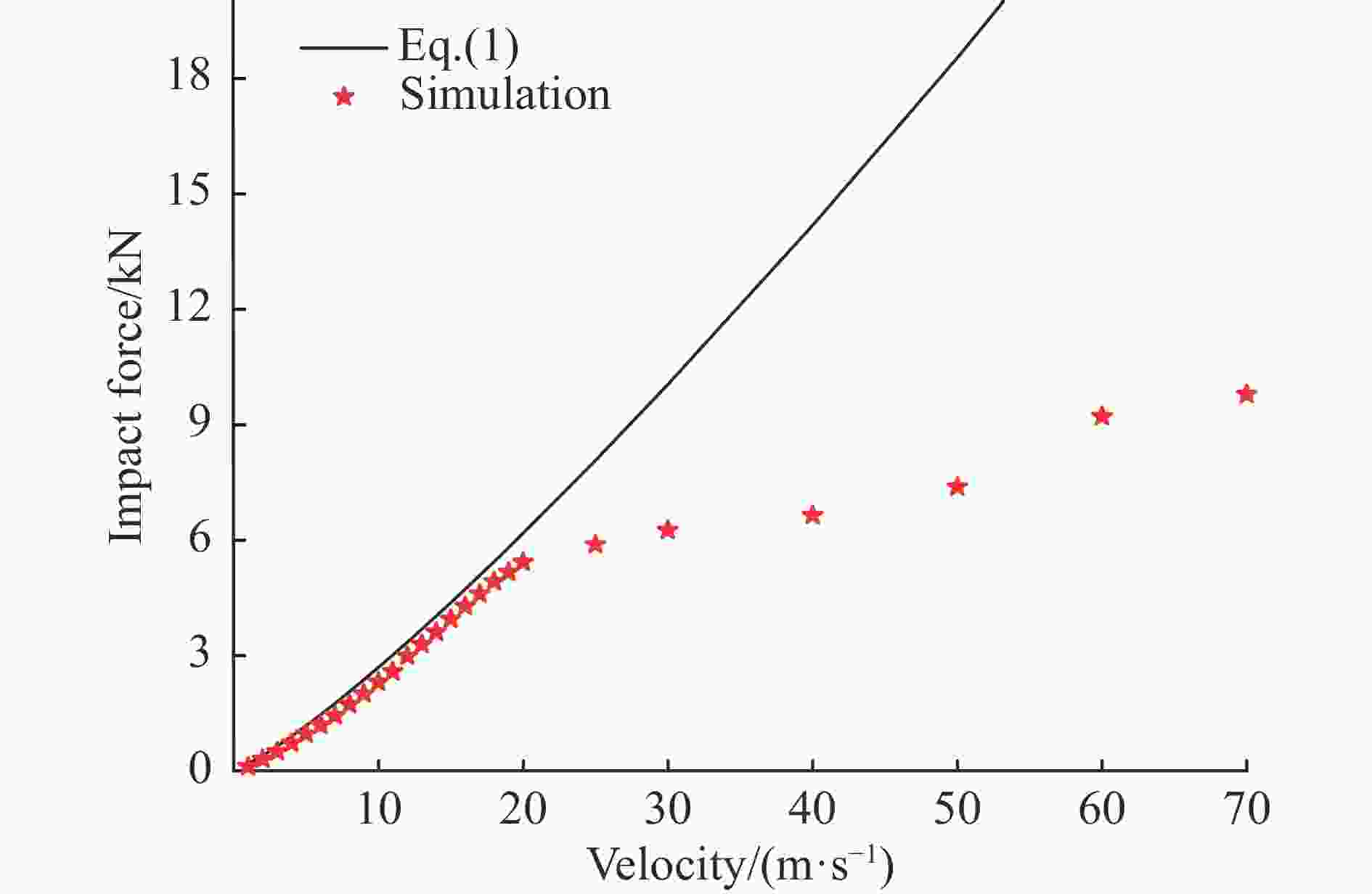

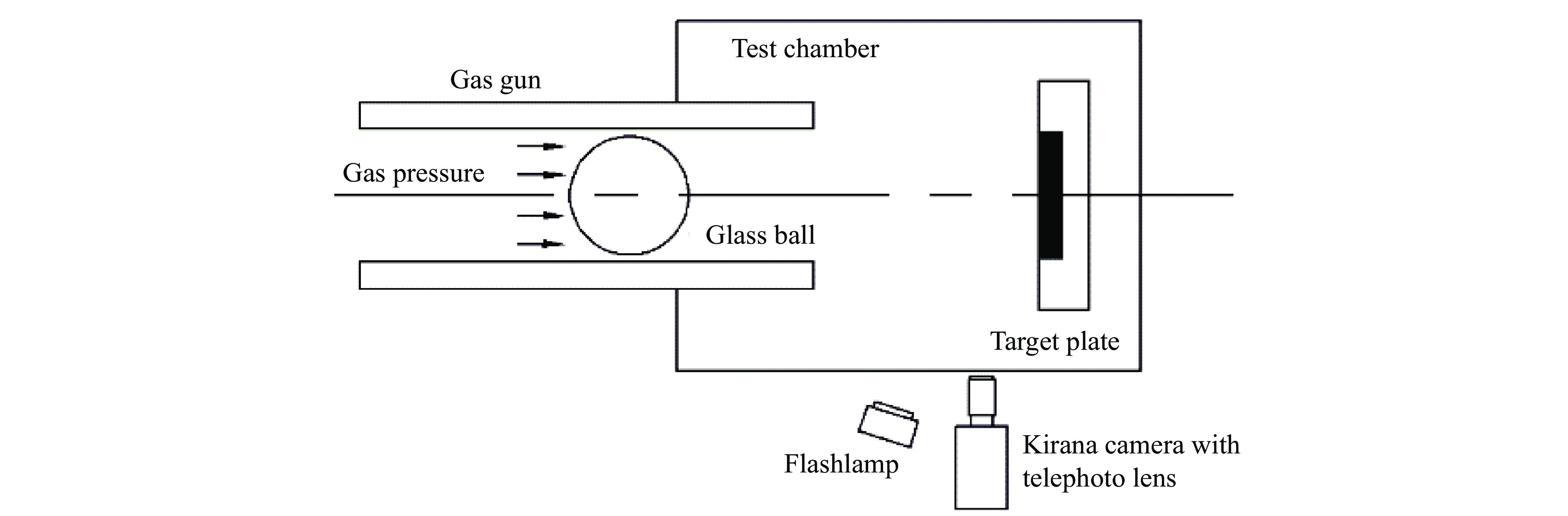

摘要: 利用高速枪对石英玻璃球撞击刚性靶板进行了实验研究,分析了不同速度下球体的破碎过程和失效模式。当冲击速度低于临界破坏速度时,石英玻璃球以略低于原速从靶板回弹;当超过临界破坏速度时,球体呈现“压缩破碎区-表面剥落区-剪切破坏区”的破坏结构;进一步提高碰撞速度,剪切破坏区的扩展导致球体碎裂为若干“月牙状”的碎块;更高撞击速度下,石英玻璃球发生坍塌式破碎,在远离撞击端处产生层裂现象。利用离散元软件对球体的撞击破坏过程进行了模拟研究,球体在高速碰撞下的破碎可以分为弹性压缩、整体破碎和二次撞击3个阶段。球体碎裂前Hertz接触理论可以较好描述其撞击力,而破碎后的撞击力由于碎裂卸载远小于理论值,且偏差随冲击速度逐渐增加。Abstract: The high-speed gun is used to study the impact of quartz glass ball on rigid target plate. The crushing process and failure mode of the ball at different speeds are analyzed. When the impact velocity is lower than the critical failure velocity, the quartz glass ball rebounds from the target plate, and the rebounding speed is slightly below the original speed; when the critical speed is exceeded, the sphere exhibits a “compressed fracture zone–surface spalling zone–shear failure zone” failure structure; further increasing the collision velocity, the expansion of the shear failure zone causes the sphere to be fragmented into several “crescent” fragments. At higher impact speeds, the quartz glass ball collapses and spalls at a distance away from the impact end. Furthermore, the discrete element software is utilized to simulate the impact damage process of the sphere. The crushing of the sphere under high-speed collision can be divided into three stages: elastic compression, integral crushing, secondary impact. Before the ball breaks, the Hertz contact theory can describe its impact force well, but the crushing force is much smaller than the theoretical value due to the fracture unloading, and the deviation gradually increases with the increasing impact speed.

-

Key words:

- quartz glass /

- fragmentation /

- spallation /

- discrete element method

-

表 1 石英玻璃离散元模型的主要微观参数

Table 1. Main microscopic parameters of discrete element mode of quartz glass

Effective modulus of linear contact/GPa Normal to shear stiffness ratio of linear contact Porosity Minimum radius of particles/mm Size ratio of maximum and minimum particles Tensile strength of contact/MPa Shear strength of contact/MPa 55 2.9 0.2 0.1 1.5 300 600 表 2 石英玻璃在常态下的物理参数

Table 2. Physical properties of quartz glass under ambient condition

Method Equivalent density/(kg·m–3) Elastic modulus/GPa Poisson’s ratio Compressive strength/MPa Tensile strength/MPa Bending strength/MPa Fracture toughness/(N·m–3/2) Manufacture provide 2.203 77.8 0.170 860 50 67.0 0.78 DEM numerical simulation 2.203 78.0 0.172 798 50 67.4 0.85 -

[1] 刘瑜, 杜长龙, 付林, 等. 煤块冲击破碎速度研究 [J]. 振动与冲击, 2011, 30(3): 18–21. doi: 10.3969/j.issn.1000-3835.2011.03.005LIU Y, DU C L, FU L, et al. Impact crushing velocity of lump coal [J]. Journal of Vibration and Shock, 2011, 30(3): 18–21. doi: 10.3969/j.issn.1000-3835.2011.03.005 [2] 李艳焕, 邵良杉, 徐振亮. 煤粒冲击粉碎临界速度的数值实验分析 [J]. 振动与冲击, 2017, 36(5): 227–230.LI Y H, SHAO L B, XU Z L. Numerical analysis for critical velocity of coal impacting and comminution [J]. Journal of Vibration and Shock, 2017, 36(5): 227–230. [3] 沈位刚, 赵涛, 唐川, 等. 落石冲击破碎特征的加载率相关性研究 [J]. 工程科学与技术, 2018(1): 43–50.SHEN W G, ZHAO T, TANG C, et al. Loading rate dependency of impact induced rock fragmentation during rockfall [J]. Advanced Engineering Sciences, 2018(1): 43–50. [4] 房丽娜, 马正先, 李慧, 等. 粉碎设备及技术的发展历程与研究进展 [J]. 有色矿冶, 2005(Suppl 1): 178–180.FANG L N, MA Z X, LI H, et al. Development history and research progress of crushing equipment and technology [J]. Non-Ferrous Mining and Metallurgy, 2005(Suppl 1): 178–180. [5] ANDREWS E W, KIM K S. Threshold conditions for dynamic fragmentation of glass particles [J]. Mechanics of Materials, 1999, 31(11): 689–703. doi: 10.1016/S0167-6636(99)00024-1 [6] ANDREWS E W, KIM K S. Threshold conditions for dynamic fragmentation of ceramic particles [J]. Mechanics of Materials, 1998, 29(11): 161–180. [7] SALMAN A D, GORHAM D A. The fracture of glass spheres [J]. Powder Technology, 2000, 107(1): 179–185. [8] SALMAN A D, GORHAM D A, VERBA A. A study of solid particle failure under normal and oblique impact [J]. Wear, 1995, 186(95): 92–98. [9] SALMAN A D, REYNOLDS G K, FU J S, et al. Descriptive classification of the impact failure modes of spherical particles [J]. Powder Technology, 2004, 143(26): 19–30. [10] CHAU K T, WEI X X, WONG R H C, et al. Fragmentation of brittle spheres under static and dynamic compressions: experiments and analyses [J]. Mechanics of Materials, 2000, 32(9): 543–554. doi: 10.1016/S0167-6636(00)00026-0 [11] WU S Z, CHAU K T, YU T X. Crushing and fragmentation of brittle spheres under double impact test [J]. Powder Technology, 2004, 143/144: 41–55. doi: 10.1016/j.powtec.2004.04.028 [12] 易洪昇, 徐松林, 单俊芳, 等. 不同加载速度下脆性颗粒的破坏特性 [J]. 爆炸与冲击, 2017, 37(5): 913–922. doi: 10.11883/1001-1455(2017)05-0913-10YI H S, XU S L, SHAN J F, et al. Fracture characteristics of brittle particles at different loading velocities [J]. Explosion and Shock Waves, 2017, 37(5): 913–922. doi: 10.11883/1001-1455(2017)05-0913-10 [13] POTYONDY D O. A bonded-particle model for rock [J]. International Journal of Rock Mechanics & Mining Sciences, 2004, 41(8): 1329–1364. [14] SHEN W G, ZHAO T, CROSTA G B, et al. Analysis of impact-induced rock fragmentation using a discrete element approach [J]. International Journal of Rock Mechanics & Mining Sciences, 2017, 98: 33–38. [15] CARMONA H A, WITTEL F K, KUN F, et al. Fragmentation processes in impact of spheres [J]. Physical Review E, 2008, 77(5): 051302. [16] XIA M, ZHAO C B. Simulation of rock deformation and mechanical characteristics using clump parallel-bond models [J]. Journal of Central South University, 2014, 21(7): 2885–2893. doi: 10.1007/s11771-014-2254-3 [17] YANG B, JIAO Y, LEI S. A study on the effects of microparameters on macroproperties for specimens created by bonded particles [J]. Engineering Computations, 2006, 23(6): 607–631. doi: 10.1108/02644400610680333 [18] PARK J W, SONG J J. Numerical simulation of a direct shear test on a rock joint using a bonded-particle model [J]. International Journal of Rock Mechanics & Mining Sciences, 2009, 46(8): 1315–1328. [19] 熊迅, 李天密, 马棋棋, 等. 石英玻璃圆环高速膨胀碎裂过程的离散元模拟 [J]. 力学学报, 2018, 50(3): 178–188.XIONG X, LI T M, MA Q Q, et al. Discrete element simulation of the high velocity expansion and fragmentation of quartz glass rings [J]. Chinese Journal Theoretical and Applied Mechanics, 2018, 50(3): 178–188. [20] KNIGHT C G, SWAIN M V, CHAUDHRI M M. Impact of small steel spheres on glass surfaces [J]. Journal of Materials Science, 1977, 12(8): 1573–1586. doi: 10.1007/BF00542808 -

下载:

下载: