Effect of Al/O Ratio on Underwater Explosion Load and Energy Output Configuration of Aluminized Explosive

-

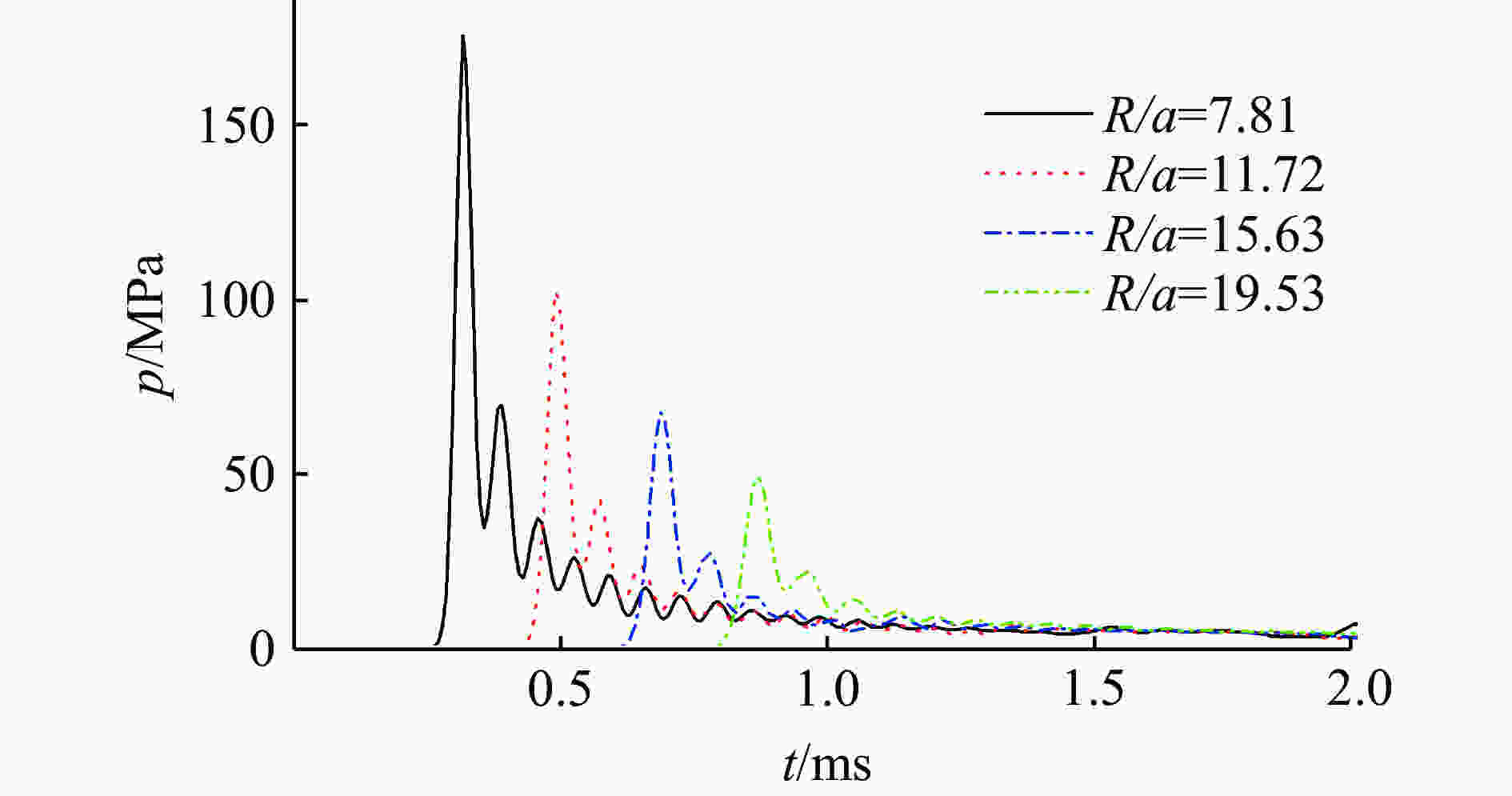

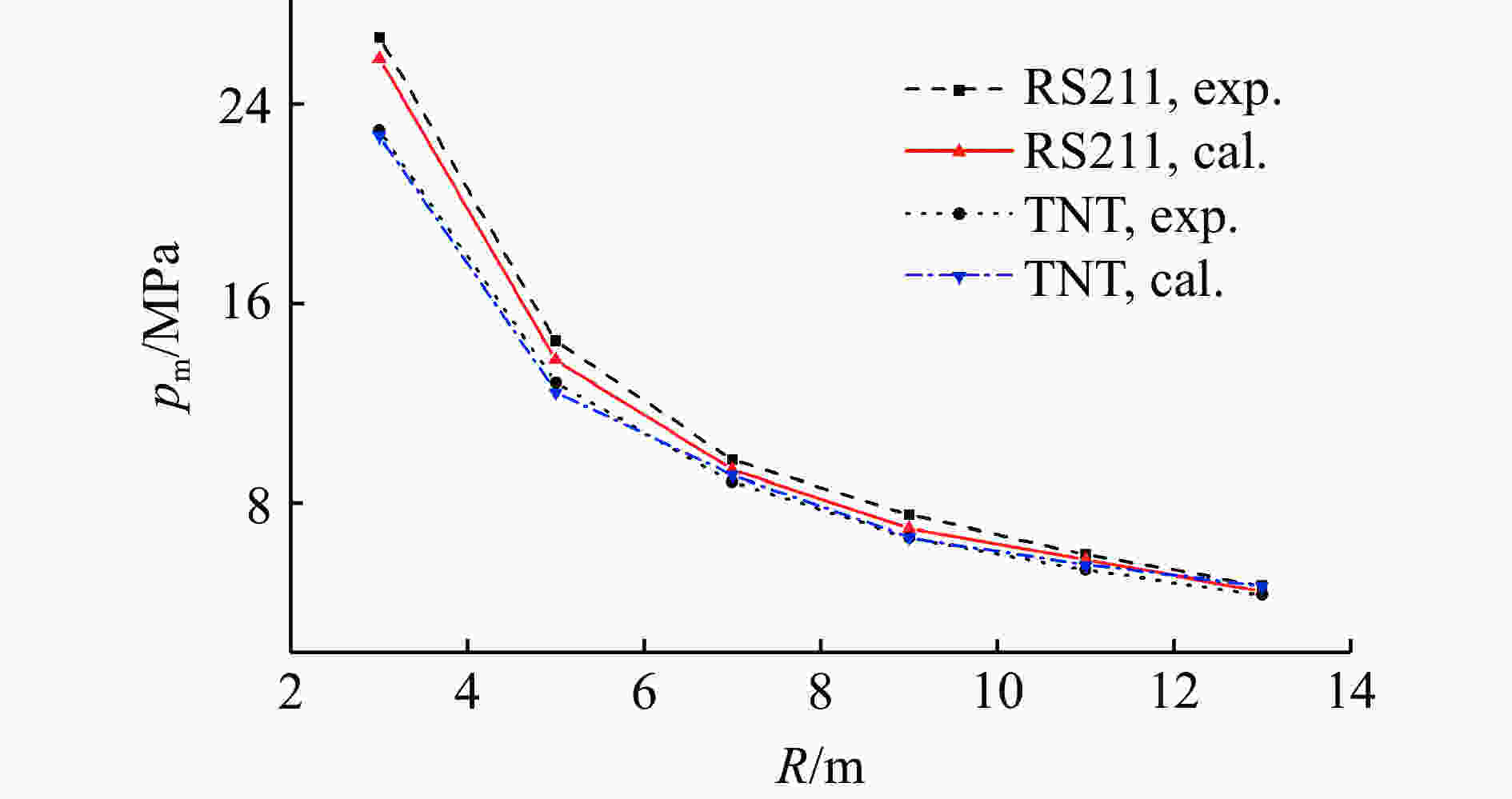

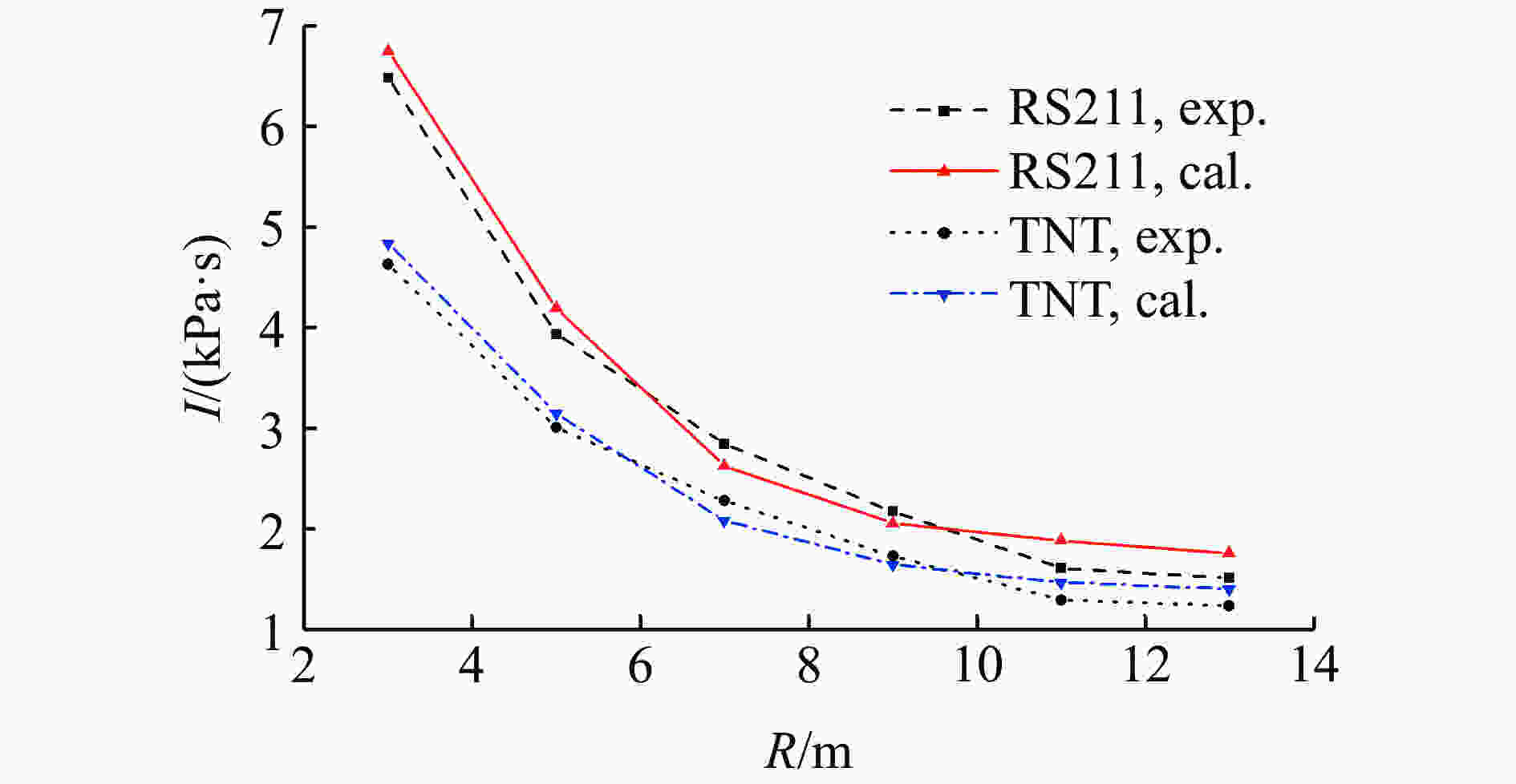

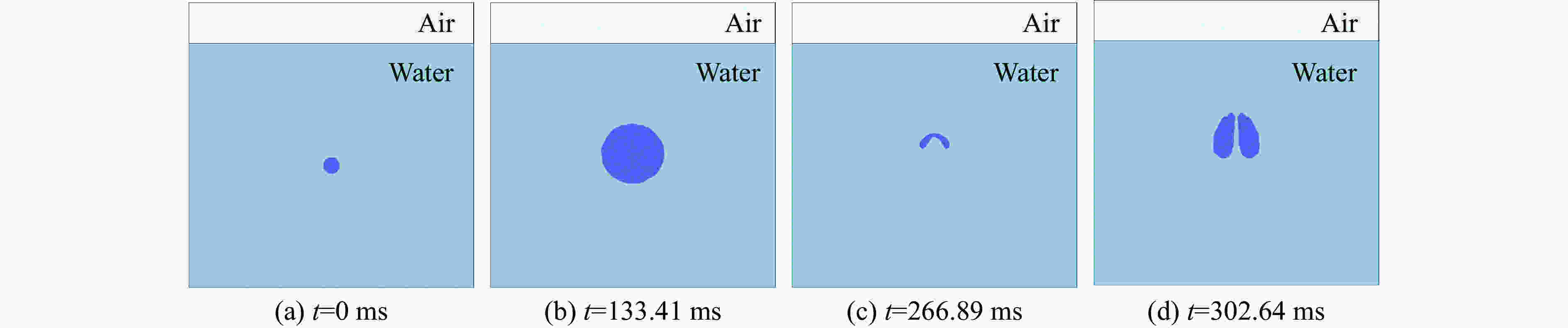

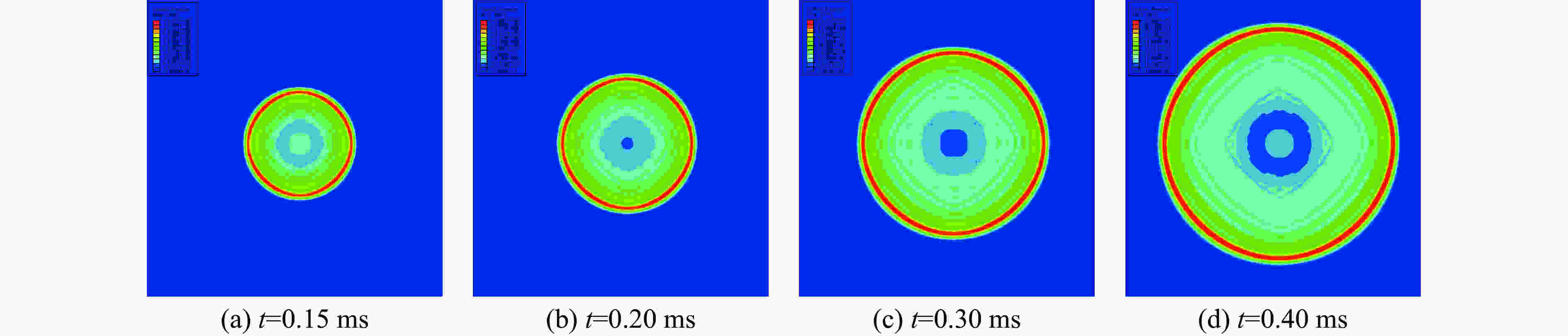

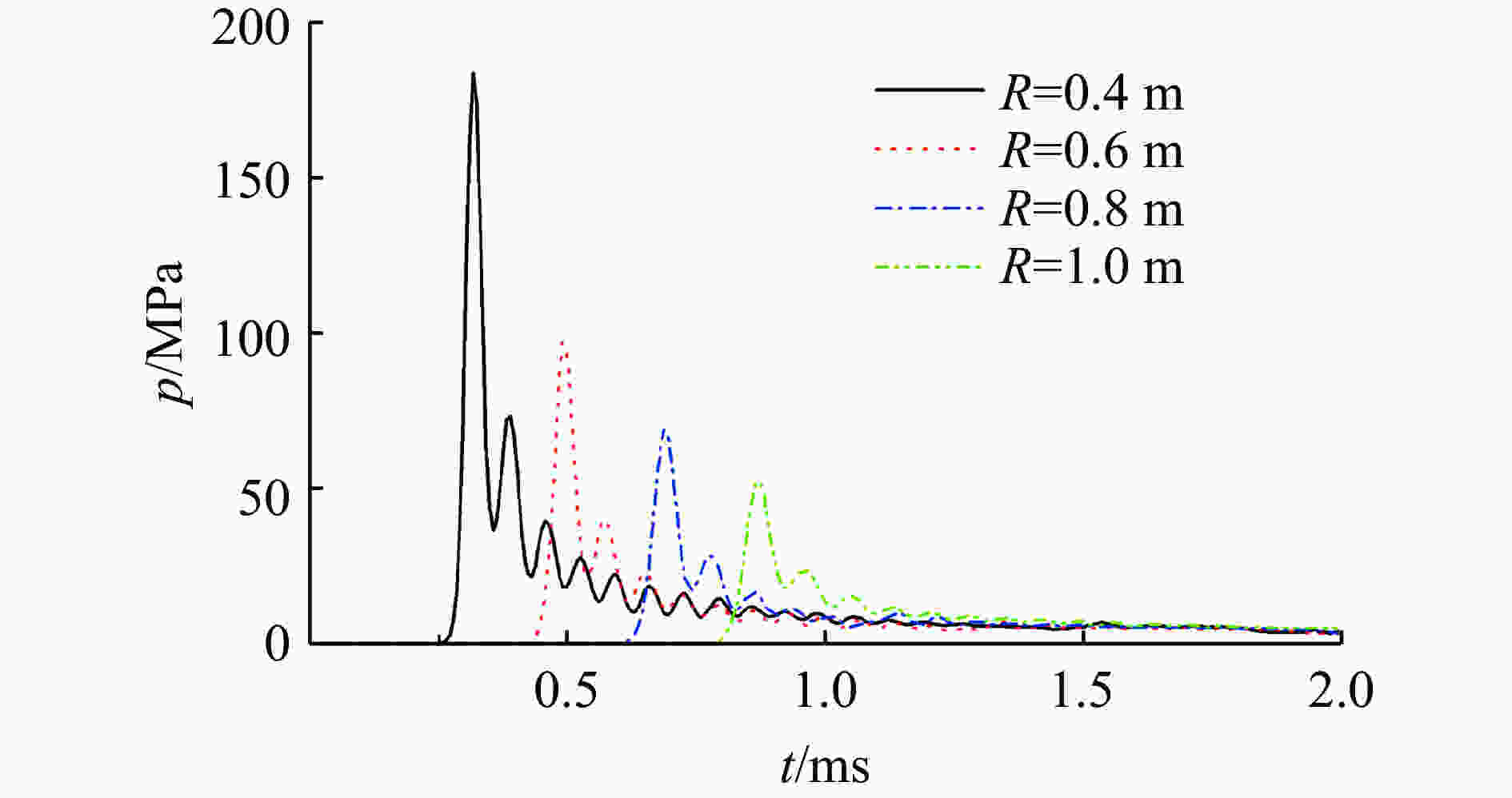

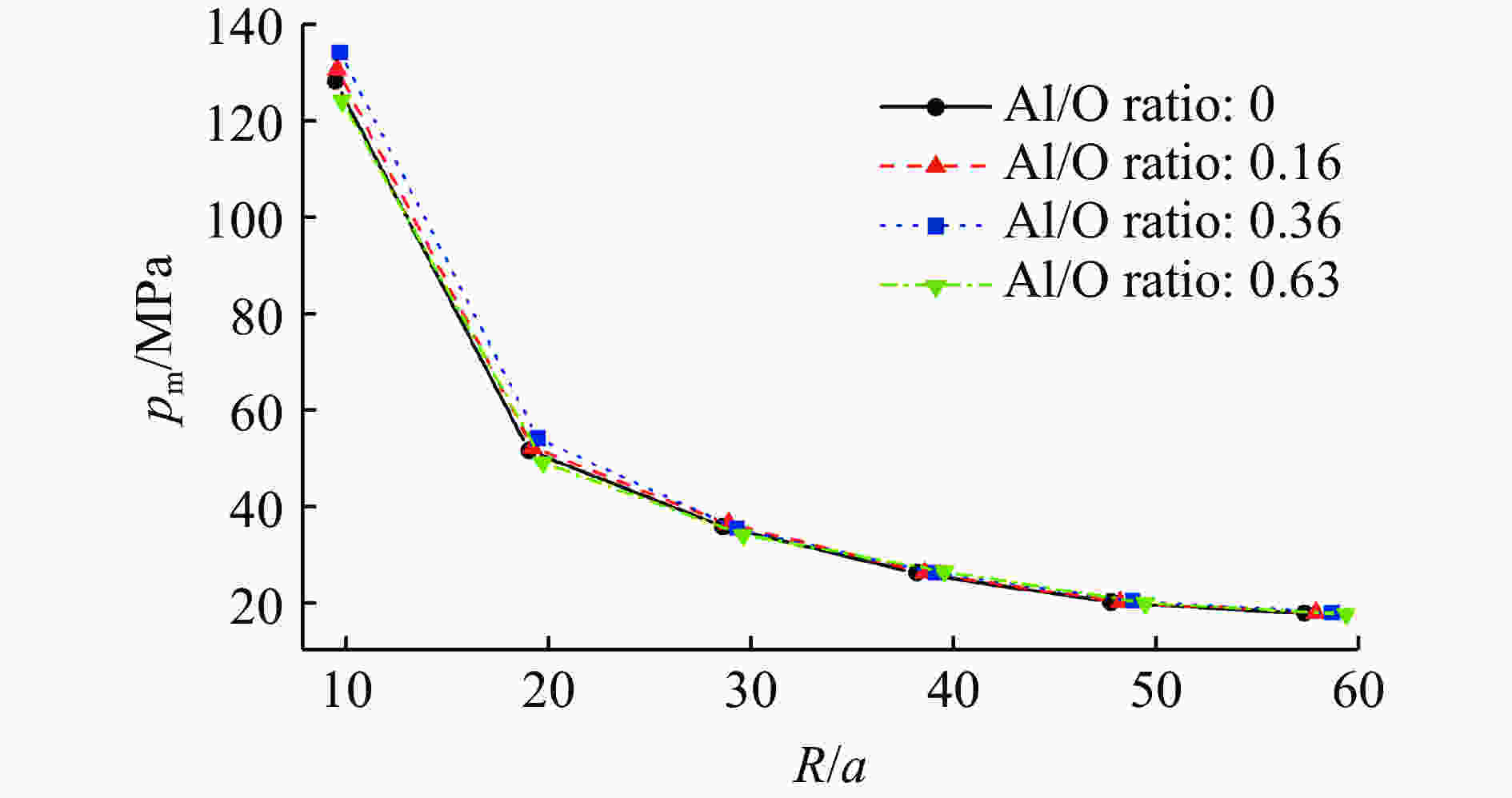

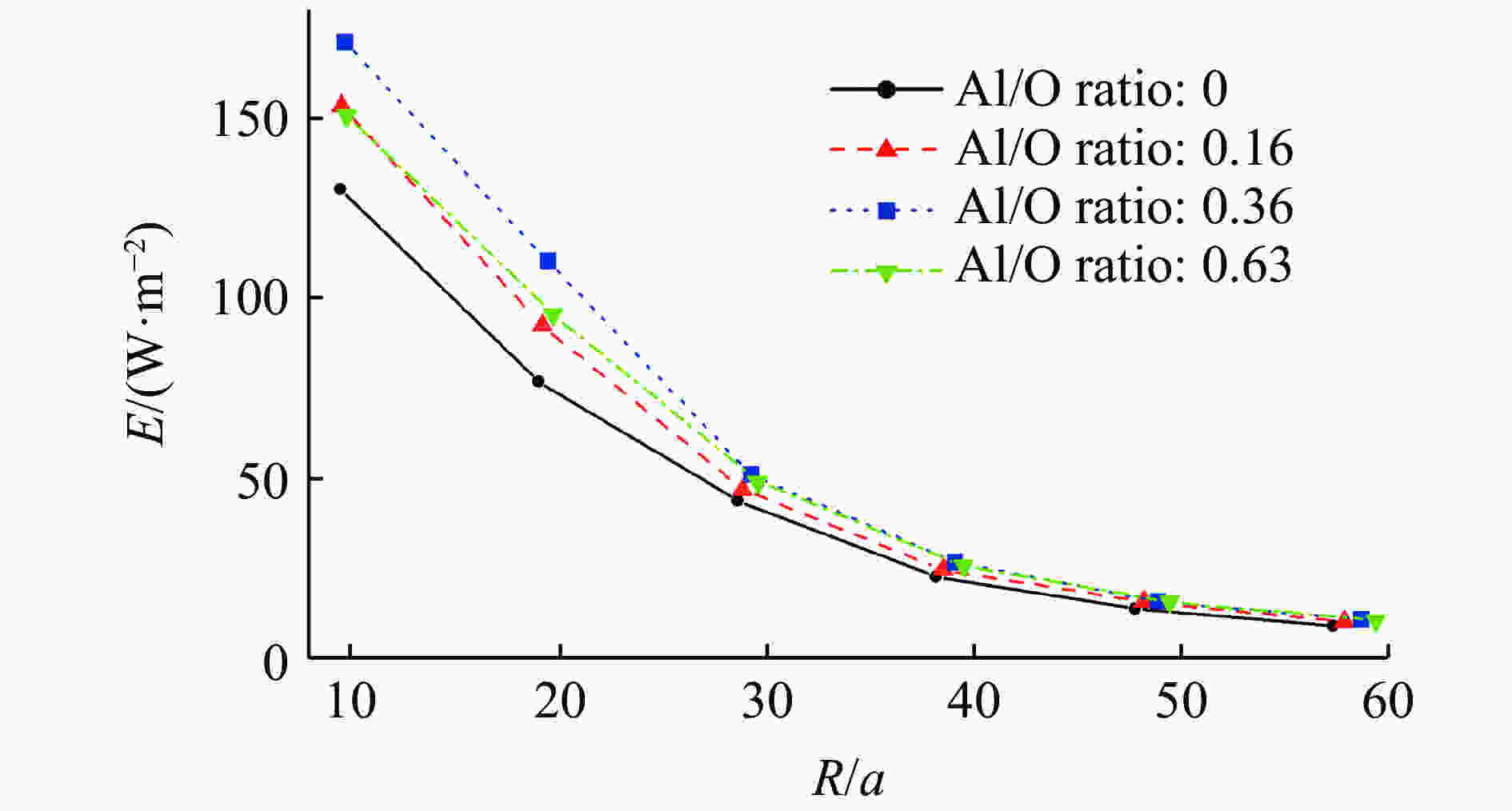

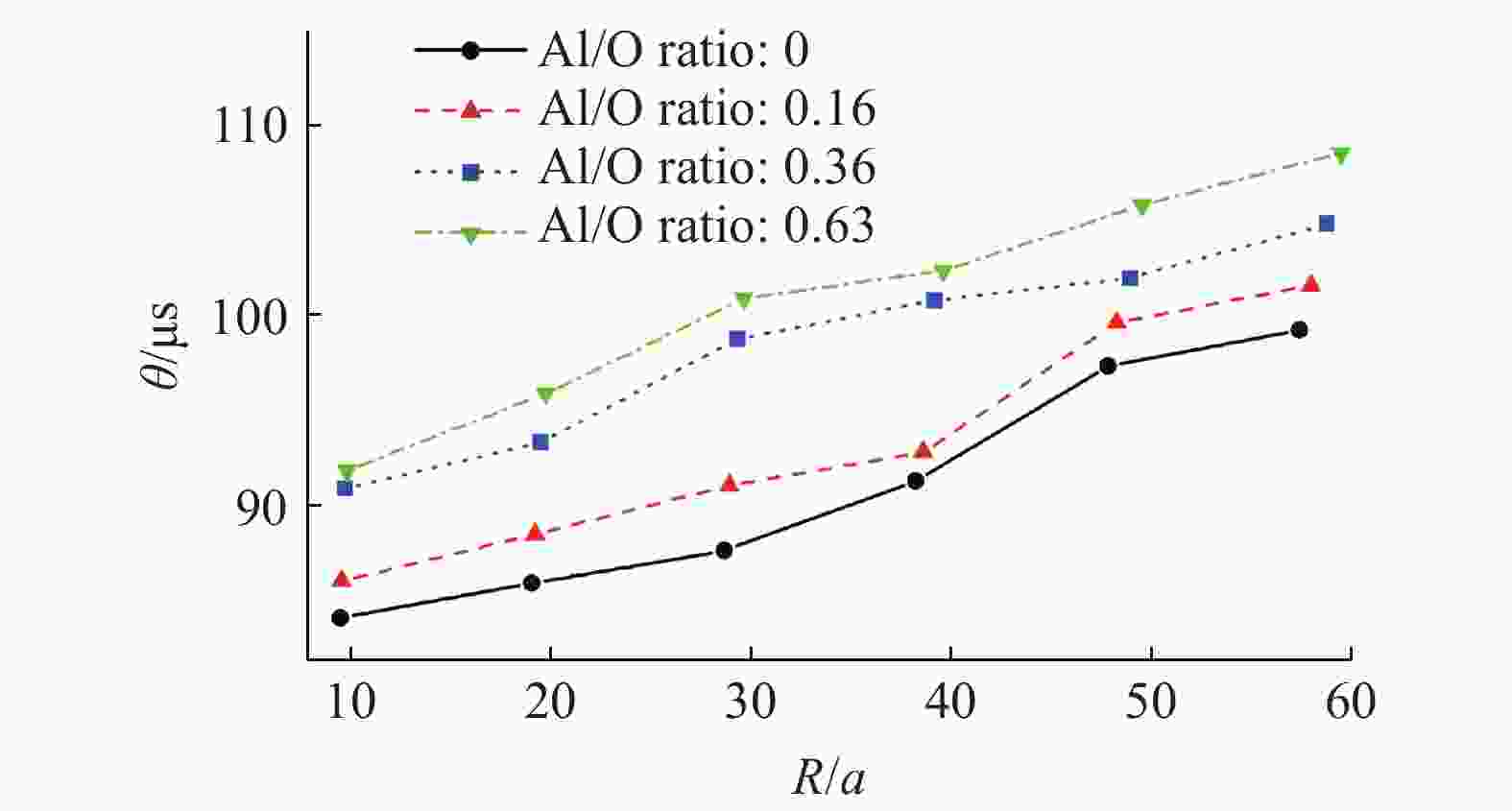

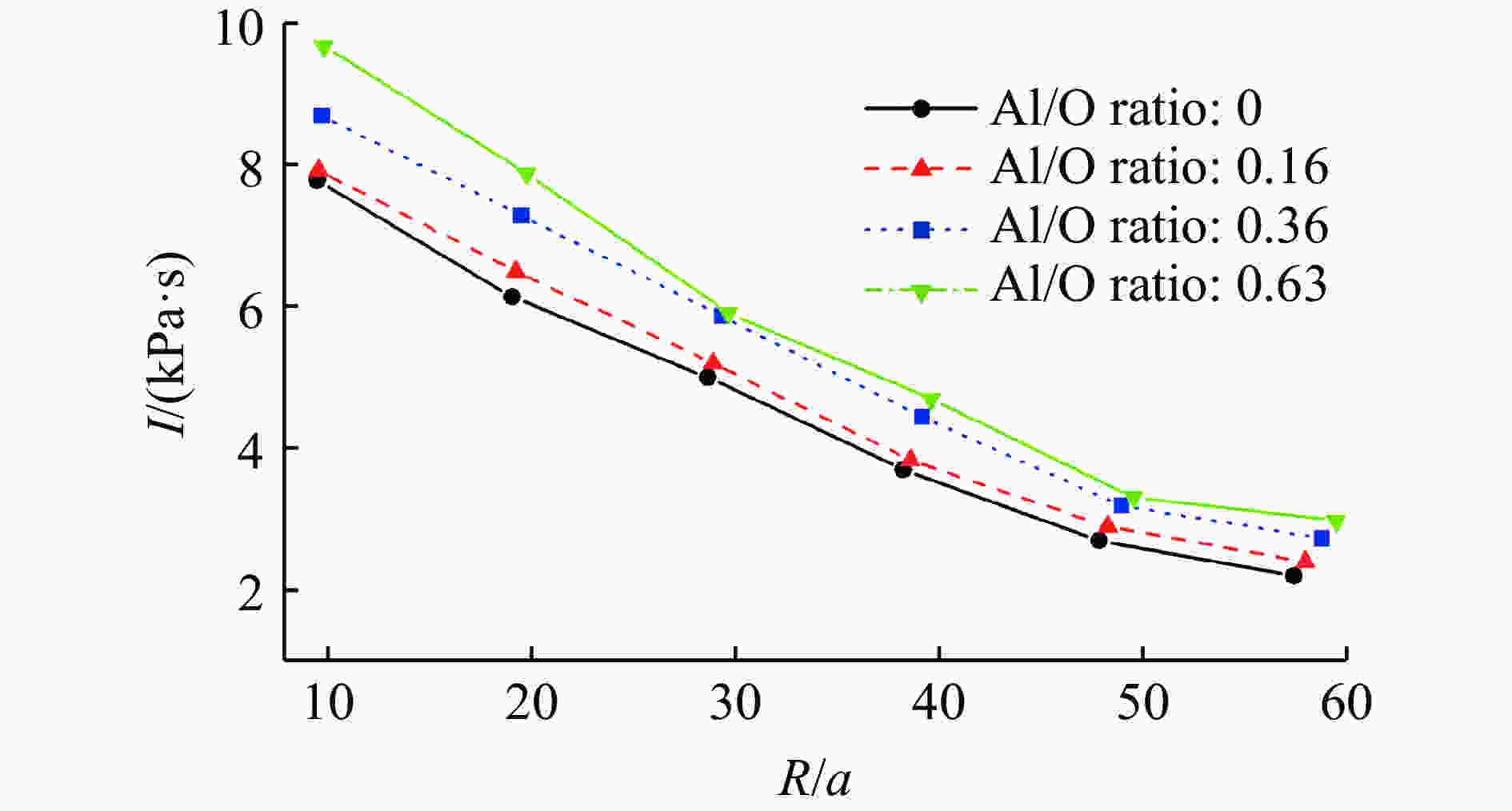

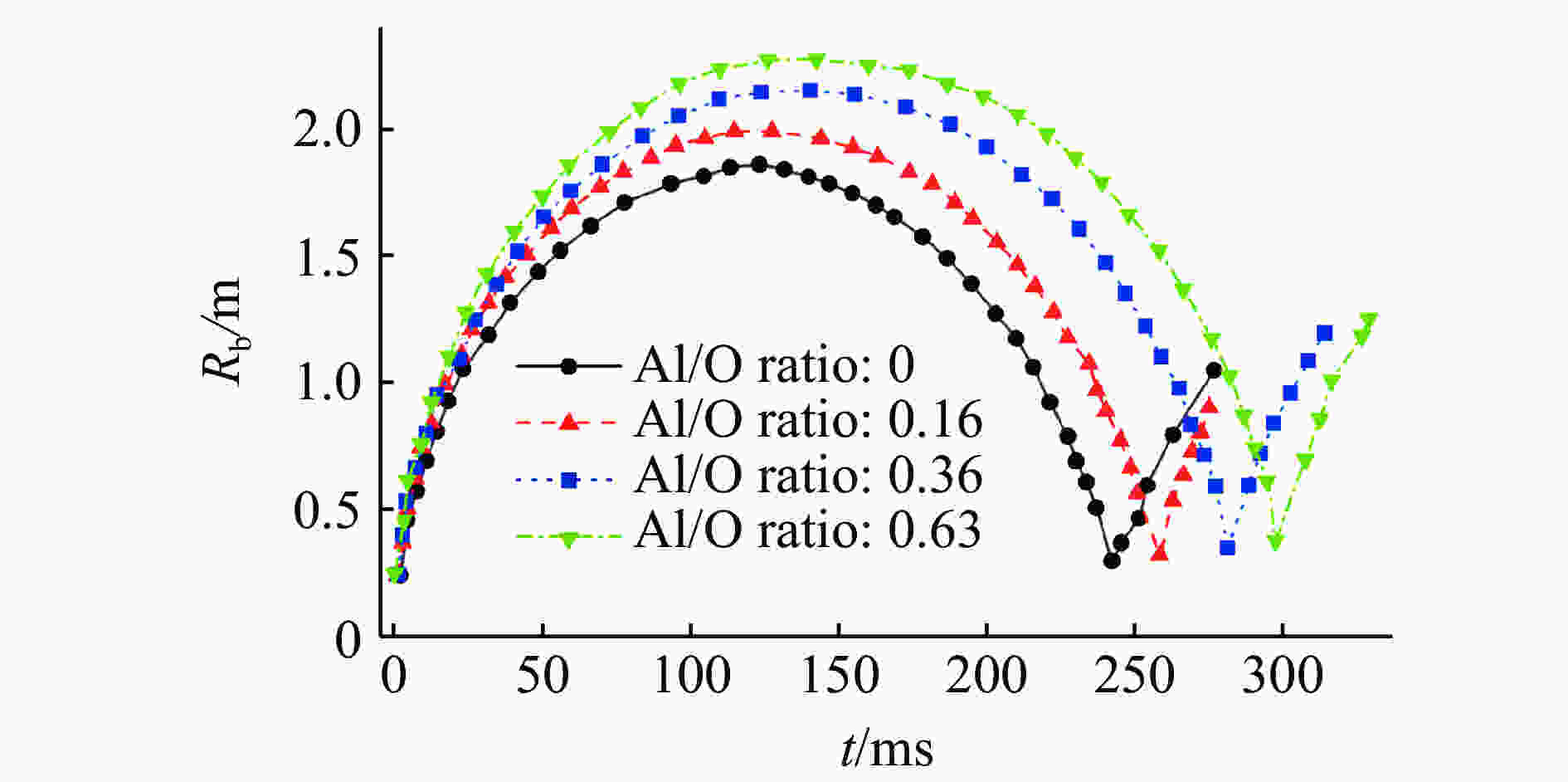

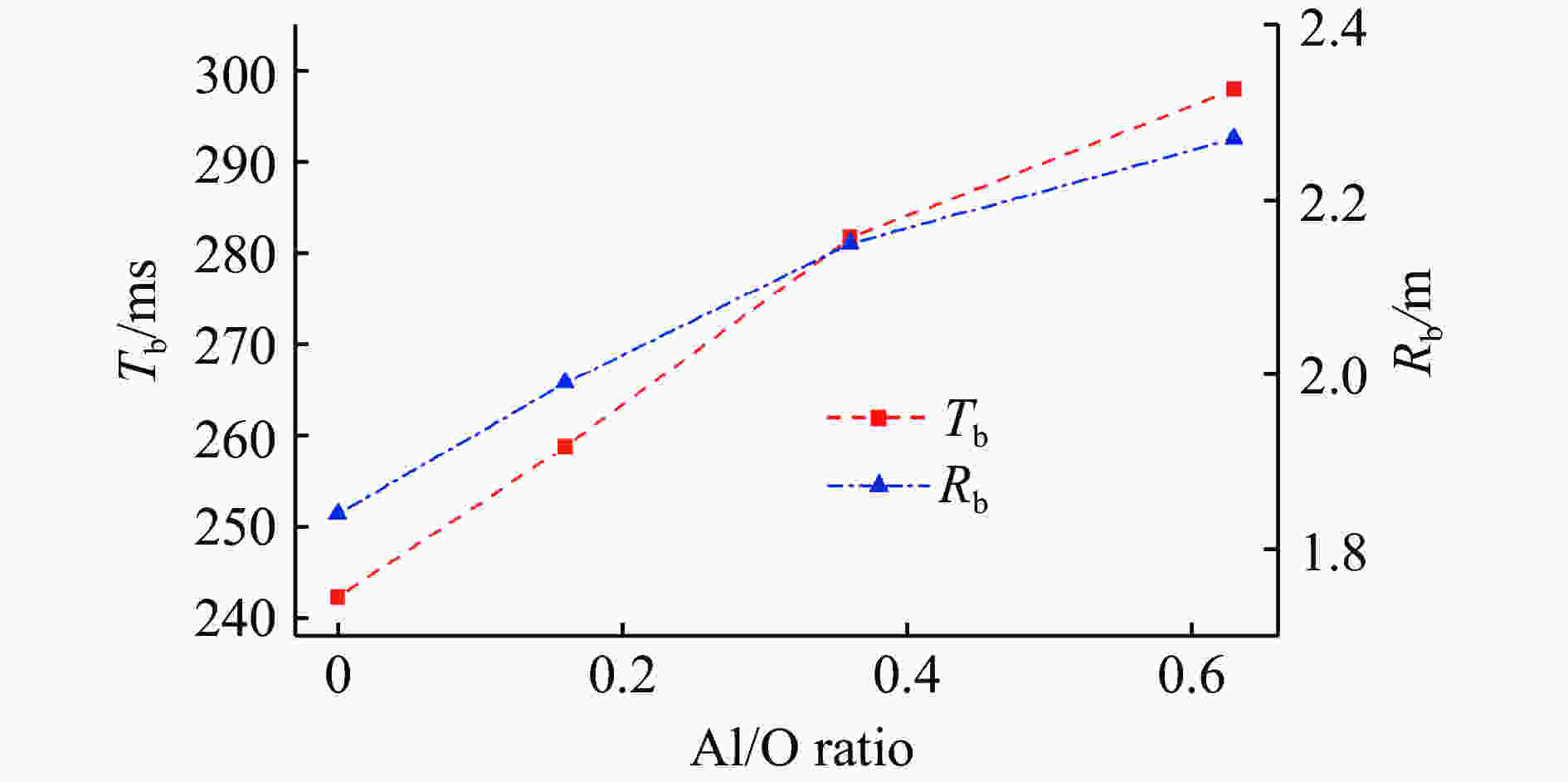

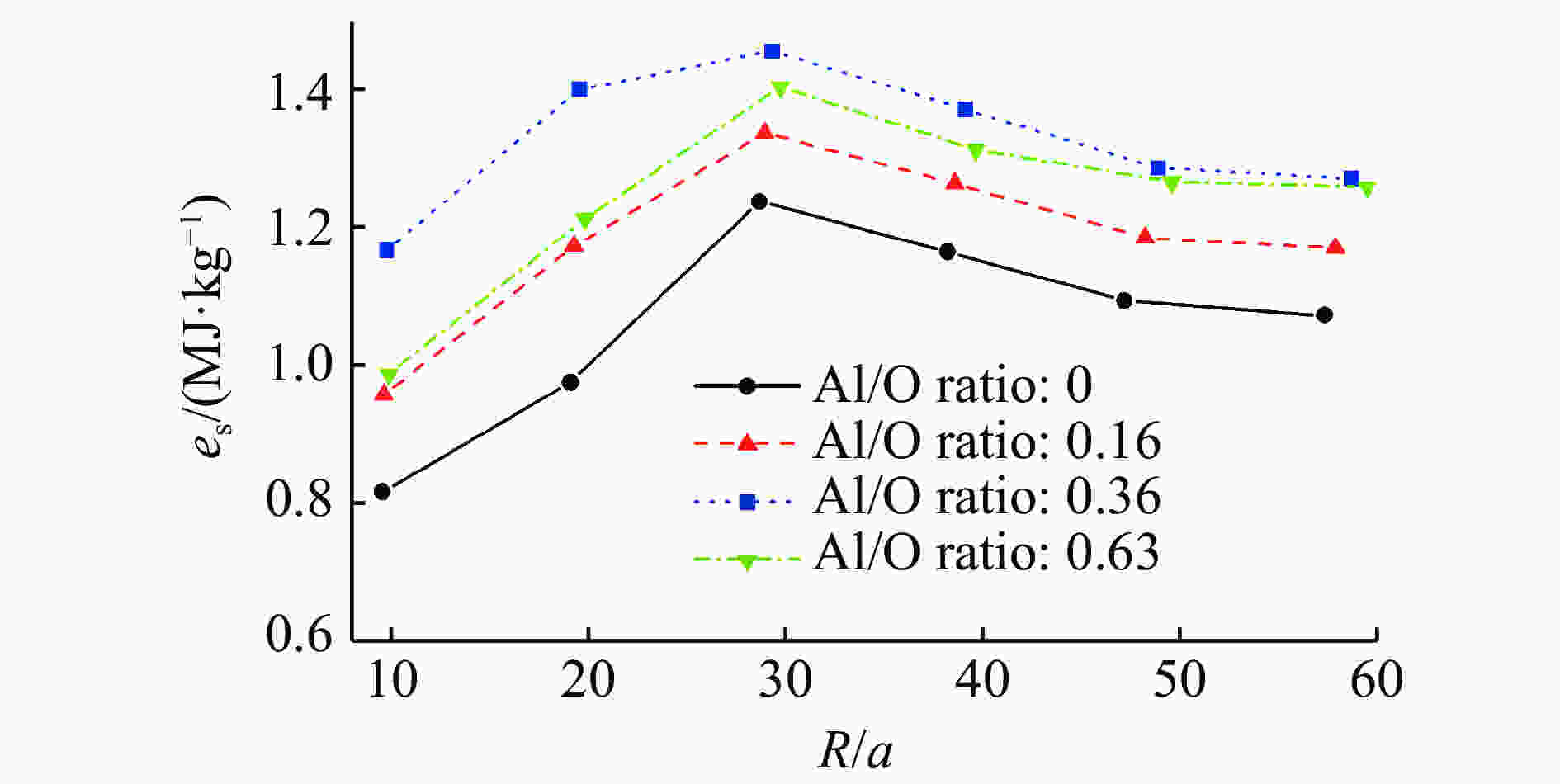

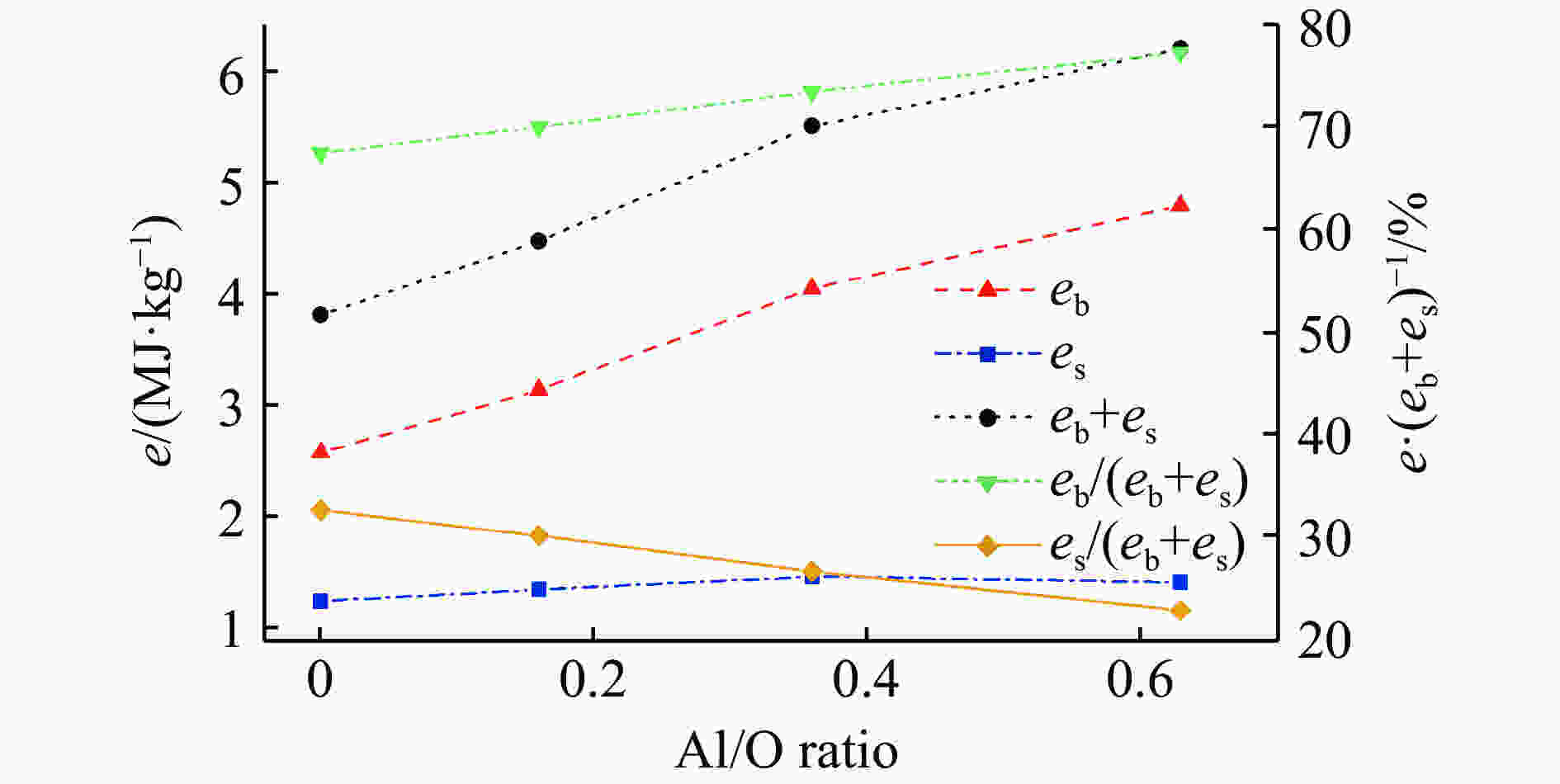

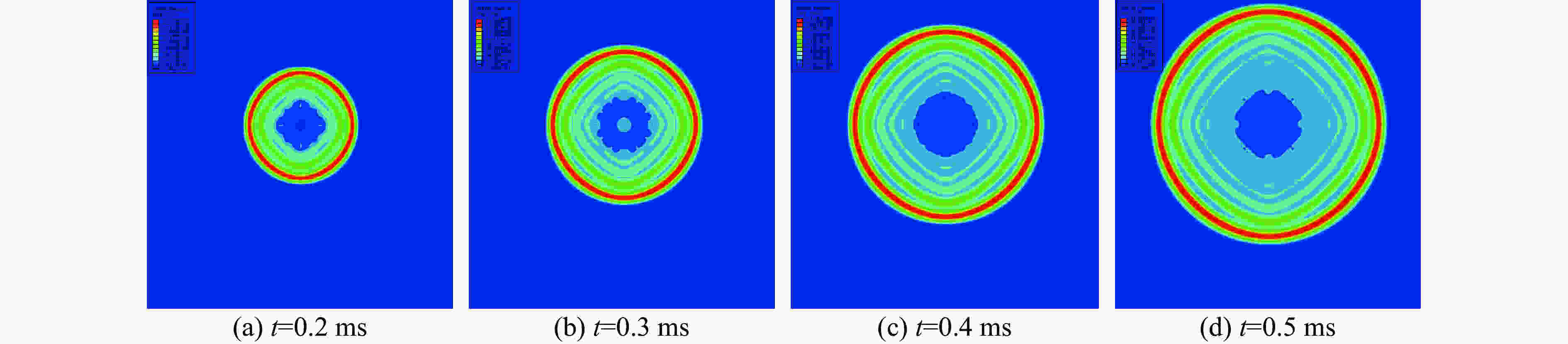

摘要: 为了系统地研究铝氧比对含铝炸药水下爆炸载荷及能量输出结构的影响,在验证数值模型有效性的基础上,针对铝氧比分别为0、0.16、0.36、0.63的RDX基含铝炸药,利用耦合欧拉-拉格朗日方法模拟了其水下爆炸连续的全过程,考虑了冲击波载荷和气泡载荷之间的耦合作用,从冲击波、气泡和能量输出结构三方面对影响效应进行评估。计算结果表明:随着铝氧比的增大,含铝炸药水下爆炸冲击波衰减时间常数、冲击波冲量、气泡脉动周期、气泡最大半径以及比气泡能都增大;铝氧比为0.36时,冲击波峰值压力、冲击波能流密度和比冲击波能达到最大。铝粉的加入对气泡能的提高相对于冲击波能更加显著。Abstract: In order to study the effect of Al/O ratio on underwater explosion load and energy output configuration of aluminized explosives systematically, four kinds of aluminized explosives are taken into account, and their Al/O ratio are 0, 0.16, 0.36 and 0.63, respectively. Coupled Eulerian-Lagrangian method was used to simulate the whole process of underwater explosion of four kinds of aluminized explosives on the basis of verifying the effectiveness of numerical method. The coupling effect between shock wave and bubble was considered in the numerical simulation. The impact effect is explained from three aspects: shock wave, bubble and energy output configuration. Simulation results show that with the increase of Al/O ratio, shock wave attenuation constant, shock wave impulse, bubble period, bubble maximum radius and specific bubble energy of underwater explosion of aluminized explosives all increase. Shock wave peak pressure, energy flow density and specific shock wave energy reach the maximum when Al/O ratio is 0.36. The addition of aluminum improves bubble energy more significantly than shock wave energy.

-

Key words:

- aluminized explosive /

- Al/O ratio /

- underwater explosion /

- shock wave /

- bubble /

- energy output

-

Sample $\rho $/(kg·m–3) A/GPa B/GPa R1 R2 ω e/(J·g–1) TNT 1 630 371.20 3.21 4.15 0.95 0.30 4 290 RS211 1 750 758.00 8.51 4.90 1.10 0.20 4 509 1(0) 1 667 334.77 9.50 6.71 1.26 0.21 5 636 2(0.16) 1 720 361.55 27.42 4.81 1.89 0.32 6 206 3(0.36) 1 788 709.60 20.27 5.37 1.90 0.34 6 956 4(0.63) 1 853 761.51 9.16 5.45 1.74 0.23 7 441 表 2 气泡周期和比气泡能的对比

Table 2. Comparison of bubble period and specific bubble energy

Explosive Tb/ms Eb/MJ eb/(MJ·kg–1) eb/eb, TNT Exp. Cal. Exp. Cal. Exp. Cal. Exp. Cal. RS211 273.33 266.89 9.441 7 8.789 9 3.059 5 2.846 5 1.52 1.48 TNT 235.99 232.56 6.097 2 5.815 6 2.017 2 1.928 9 1.00 1.00 -

[1] 陈朗, 龙新平, 冯长根, 等. 含铝炸药爆轰[M]. 北京: 国防工业出版社, 2004: 1–3.CHEN L, LONG X P, FENG C G, et al. Detonation of aluminized explosives [M]. Beijing: National Defense Industry Press, 2004: 1–3. [2] 周霖, 徐少辉, 徐更光. 炸药水下爆炸能量输出特性研究 [J]. 兵工学报, 2006(2): 235–238. doi: 10.3321/j.issn:1000-1093.2006.02.011ZHOU L, XU S H, XU G G. Research on energy output characteristics for underwater explosion of explosives [J]. Acta Armamentarii, 2006(2): 235–238. doi: 10.3321/j.issn:1000-1093.2006.02.011 [3] 赵继波, 李金河, 谭多望, 等. 铝氧比对水中爆炸近场冲击波的影响 [J]. 含能材料, 2009, 17(4): 420–423. doi: 10.3969/j.issn.1006-9941.2009.04.011ZHAO J B, LI J H, TAN D W, et al. Effects of ratios of aluminum to oxygen on shock wave of cylindrical charge at underwater explosive close-field [J]. Chinese Journal of Energetic Materials, 2009, 17(4): 420–423. doi: 10.3969/j.issn.1006-9941.2009.04.011 [4] 赵倩, 聂建新, 王秋实, 等. 含铝炸药水下爆炸及其对舰船毁伤的数值模拟 [J]. 兵工学报, 2017, 38(2): 298–304. doi: 10.3969/j.issn.1000-1093.2017.02.013ZHAO Q, NIE J X, WANG Q S, et al. Numerical simulation on underwater explosion of aluminized explosives and its damage to ship [J]. Acta Armamentarii, 2017, 38(2): 298–304. doi: 10.3969/j.issn.1000-1093.2017.02.013 [5] 门建兵, 蒋建伟, 王树有. 爆炸冲击数值模拟技术基础 [M]. 北京: 北京理工大学出版社, 2015: 99–101.MEN J B, JIANG J W, WANG S Y. Fundamentals of numerical simulation for explosion and shock problems [M]. Beijing: Beijing Institute of Technology Press, 2015: 99–101. [6] NOH W F. CEL: a time-dependent two-space-dimensional coupled Eulerian-Lagrange code [M]// ALDER B, FERNBACH S, ROTENBERG M, et al. Methods in Computational Physics: Volume 3. New York: Academic Press, 1964: 117–179. [7] BENSON D J, OKAZAWA S. Contact in a muti-material Eulerian finite element formulation [J]. Computer Methods in Applied Mechanics and Engineering, 2004, 193(39): 4277–4298. [8] 李烨. 近场水下爆炸载荷及其对舰船局部结构毁伤研究[D]. 哈尔滨: 哈尔滨工程大学, 2016.LI Y. Research on near field underwater explosion loads and local structure damage of vessels [D]. Harbin: Harbin Engineering University, 2016. [9] HIBBITT H, KARLSSON B, SORENSEN P. Abaqus analysis user’s manual version 6.10 [M]. Providence, RI, USA: Dassault Systèmes Simulia Corp., 2011. [10] JACOBS S J. On the equation of state for detonation products at high density [C]//12th Symposium (International) on Combustion. Pittsburgh: The Combustion Institute, 1969. [11] 项大林, 荣吉利, 李健, 等. 基于KHT程序的RDX基含铝炸药JWL状态方程参数预测研究 [J]. 北京理工大学学报, 2013, 33(3): 239–243. doi: 10.3969/j.issn.1001-0645.2013.03.005XIANG D L, RONG J L, LI J, et al. JWL equation of state parameters prediction of RDX-based aluminized explosive based on KHT code [J]. Transactions of Beijing Institute of Technology, 2013, 33(3): 239–243. doi: 10.3969/j.issn.1001-0645.2013.03.005 [12] 郅斌伟, 张志江, 马硕, 等. 水底爆炸冲击波峰值压力数值仿真 [J]. 爆破, 2009, 26(1): 22–24, 28. doi: 10.3963/j.issn.1001-487X.2009.01.006ZHI B W, ZHANG Z J, MA S, et al. Research on shock wave peak pressure of under water explosion [J]. Blasting, 2009, 26(1): 22–24, 28. doi: 10.3963/j.issn.1001-487X.2009.01.006 [13] COLE R H. Underwater explosion [M]. New Jersey: Princeton University Press, 1948: 118–127. [14] 张远平, 池家春, 龚晏青, 等. 含铝炸药水下爆炸性能的实验研究 [J]. 高压物理学报, 2010, 24(4): 316–320. doi: 10.11858/gywlxb.2010.04.013ZHANG Y P, CHI J C, GONG Y Q, et al. Experimental study on underwater explosion performance of aluminized explosive [J]. Chinese Journal of High Pressure Physics, 2010, 24(4): 316–320. doi: 10.11858/gywlxb.2010.04.013 [15] 刘科种. 爆炸能量输出结构与高威力炸药研究[D]. 北京: 北京理工大学, 2009.LIU K Z. Study on explosive energy output structure and high explosive charge [D]. Beijing: Beijing Institute of Technology, 2009. -

下载:

下载: