Low-Velocity Impact Behavior and Damage Characteristics of CFRP Laminates

-

摘要: 为了研究碳纤维增强复合材料(Carbon Fiber Reinforced Plastics,CFRP)层合板低速冲击力学性能,开展了铺层顺序为[454/–454]4T的CFRP层合板落锤低速冲击试验。研究了条形冲锤冲击角度和半球形冲锤直径两个影响因素下的CFRP层合板低速冲击力学响应,同时通过凹坑深度和分层损伤面积研究了层合板低速冲击损伤特性。试验结果表明:当条形冲锤冲击角度与层合板表面纤维方向平行时以及以较小直径的半球形冲锤冲击时,最大中心位移和能量耗散较大,凹坑深度和分层面积也较大;在冲锤直径和冲击角度两个单因素变量下,凹坑深度与分层损伤面积成正相关;直径为10 mm的半球形冲锤冲击层合板时,在凹坑区域存在明显的纤维断裂;14 mm和16 mm半球形冲锤冲击时,损伤虽目视可见,但未见明显纤维断裂。

-

关键词:

- 碳纤维增强复合材料层合板 /

- 低速冲击 /

- 损伤特征 /

- 凹坑深度 /

- 分层损伤面积

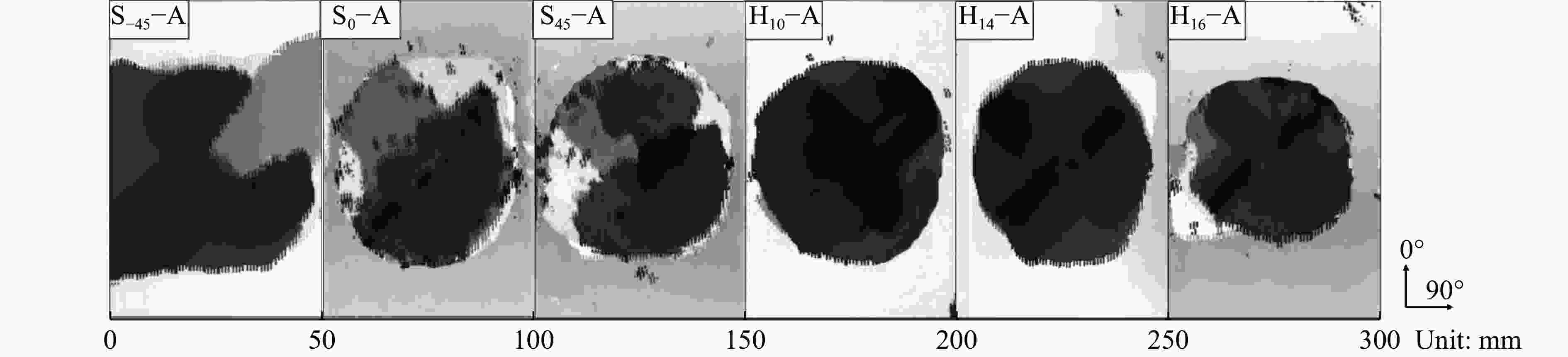

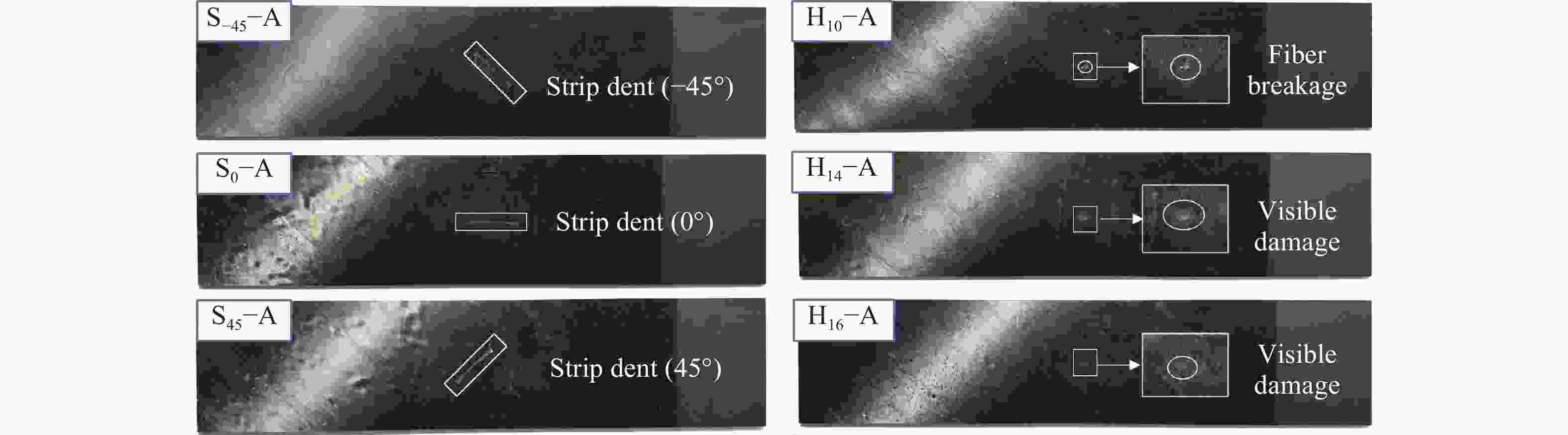

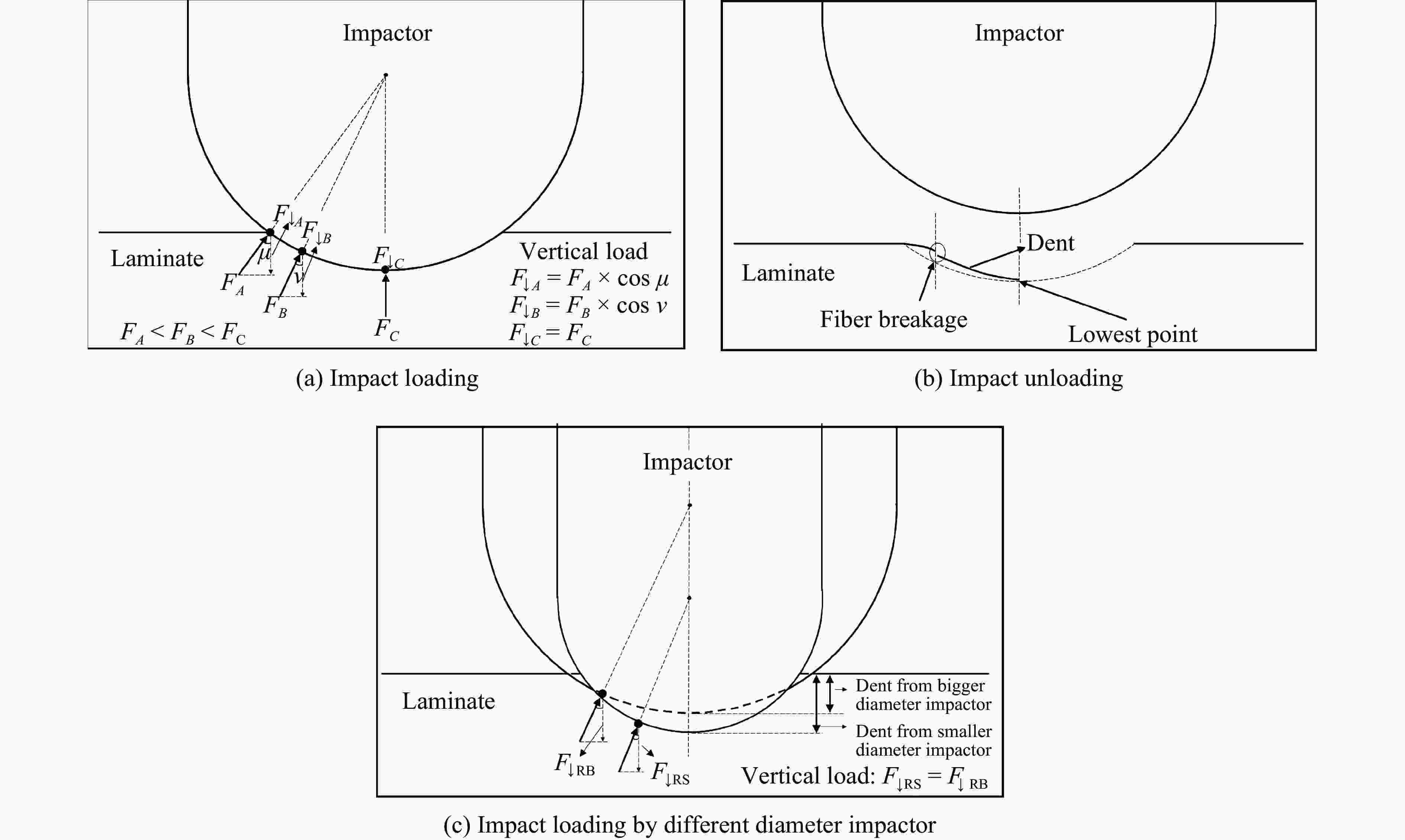

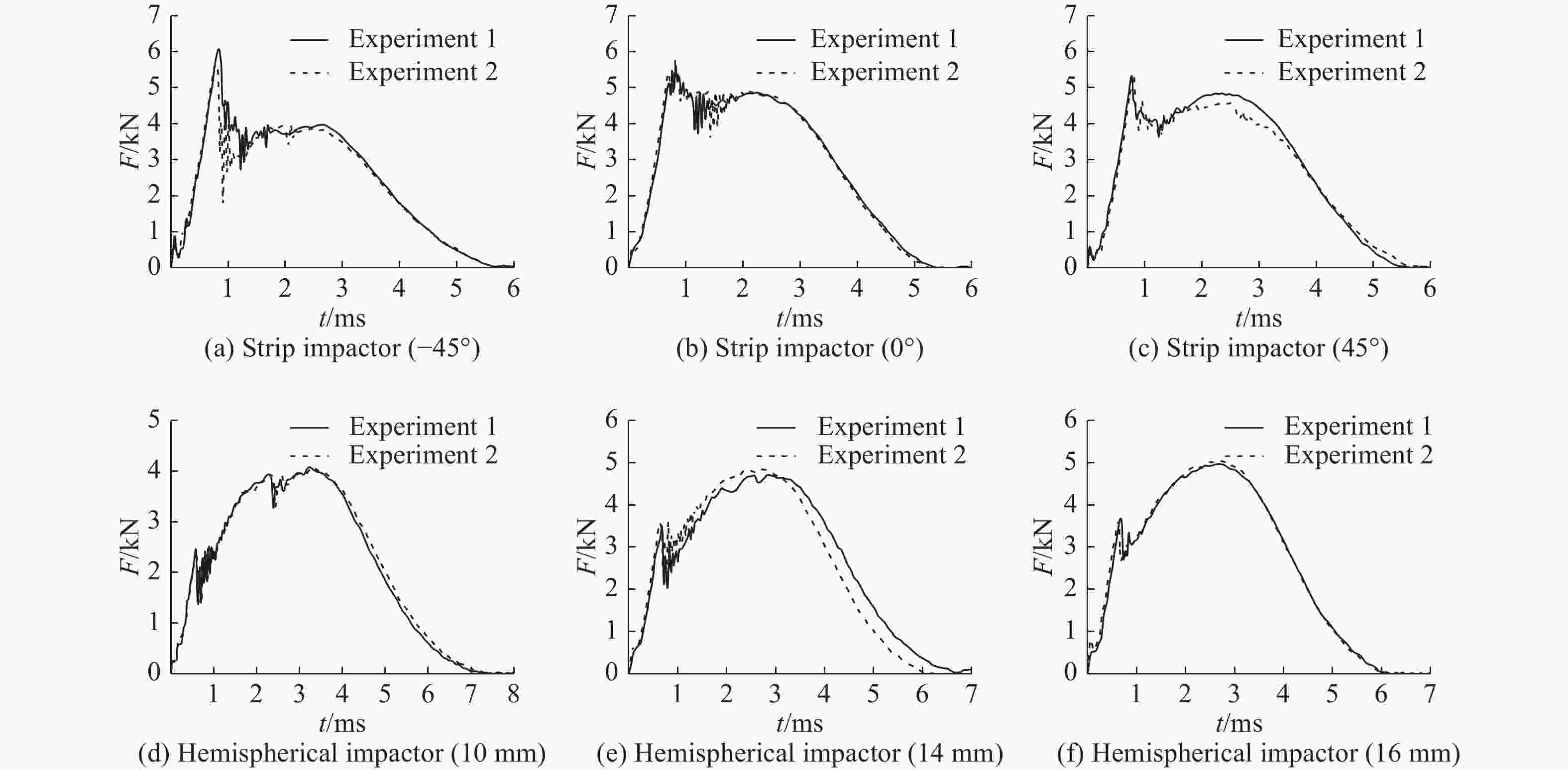

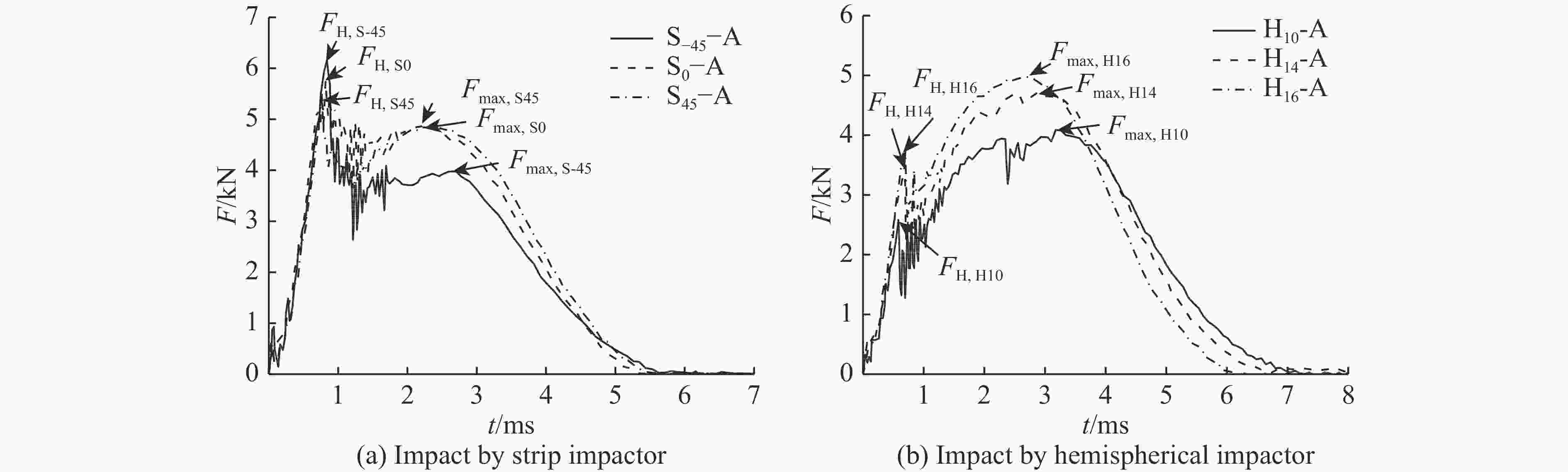

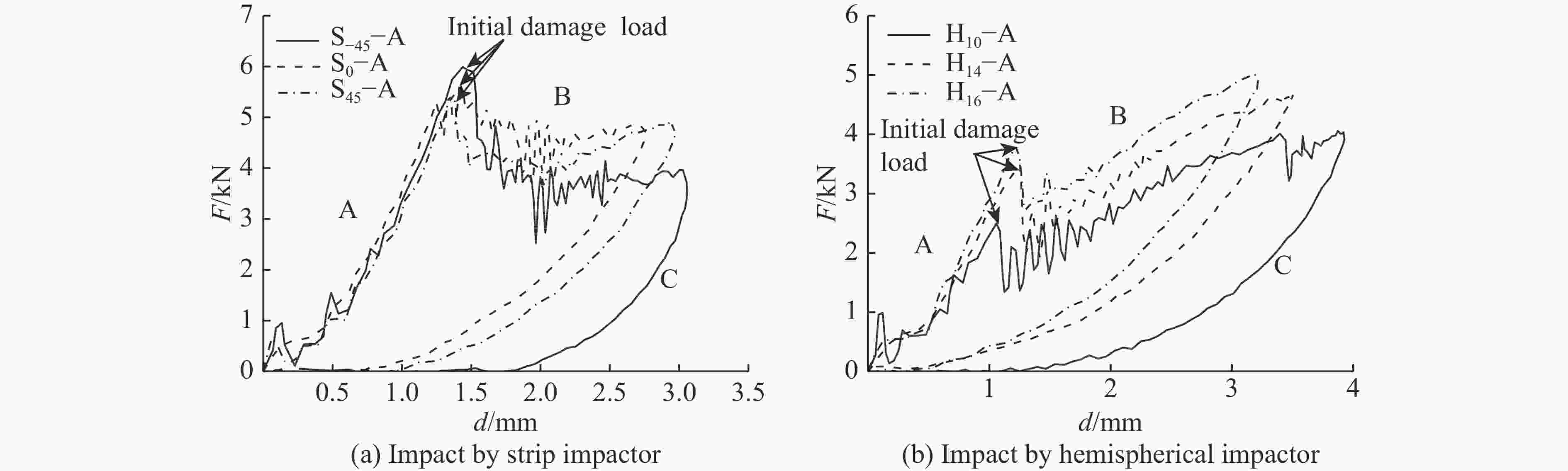

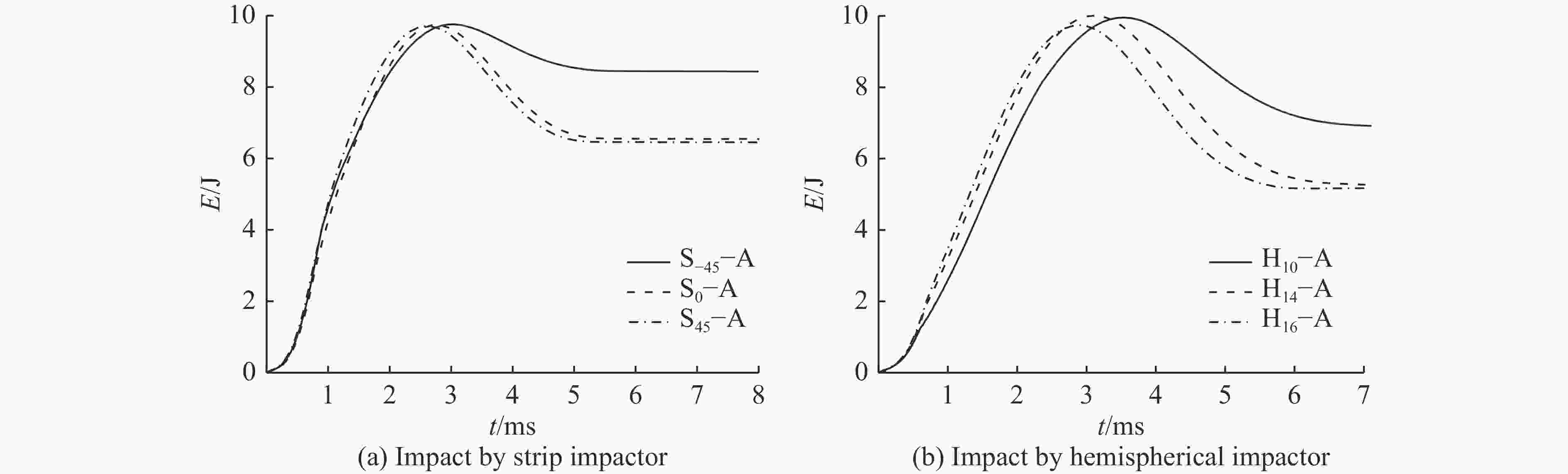

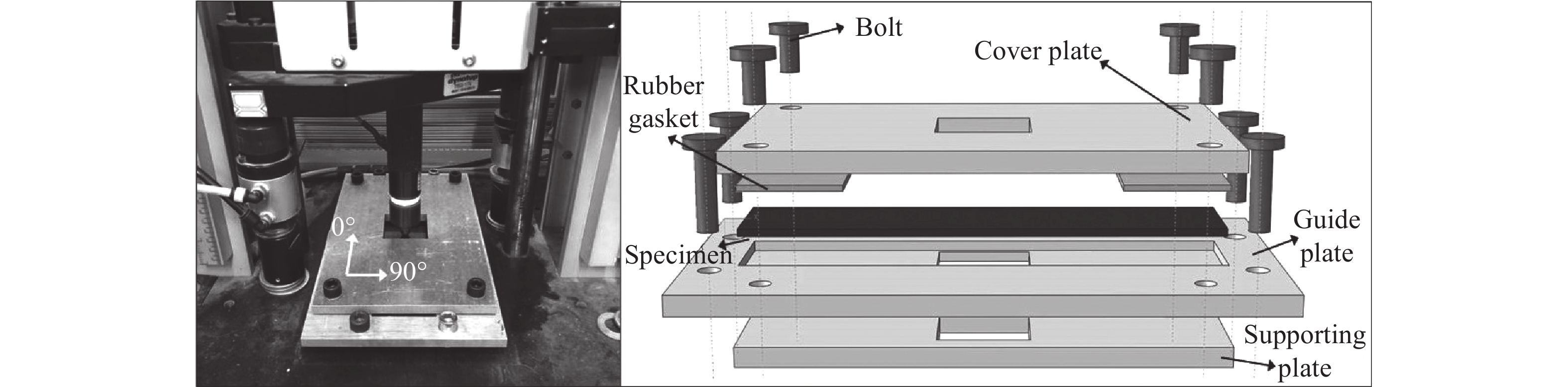

Abstract: Low-velocity impact tests were performed for the [454/–454]4T carbon fiber reinforced plastics (CFRP) laminates for exploring the low-velocity impact behaviors. The effects of impact angle of strip impactor and impactor diameter of hemispherical impactor on the impact responses of laminates are studied. Besides, the damage characteristics are evaluated by dent depth and delamination damage area simultaneously. The experimental results show that larger maximum center displacement and more energy dissipation can be caused when the impact direction of the strip impactor is parallel to the fibers in the surface plies and the impactor diameter is smaller. The dent depth and delamination damage area are also larger at the two situations above. In addition, the dent depth is positive correlated with the delamination damage area under single factor variables of impact angle and impactor diameter. There has significant fiber break around the impact area under the impact of 10 mm hemispherical impactor, but no obvious fiber break appears around the impact area for 14 mm and 16 mm impactors. -

表 1 低速冲击测试安排

Table 1. Low-velocity impact test arrangements

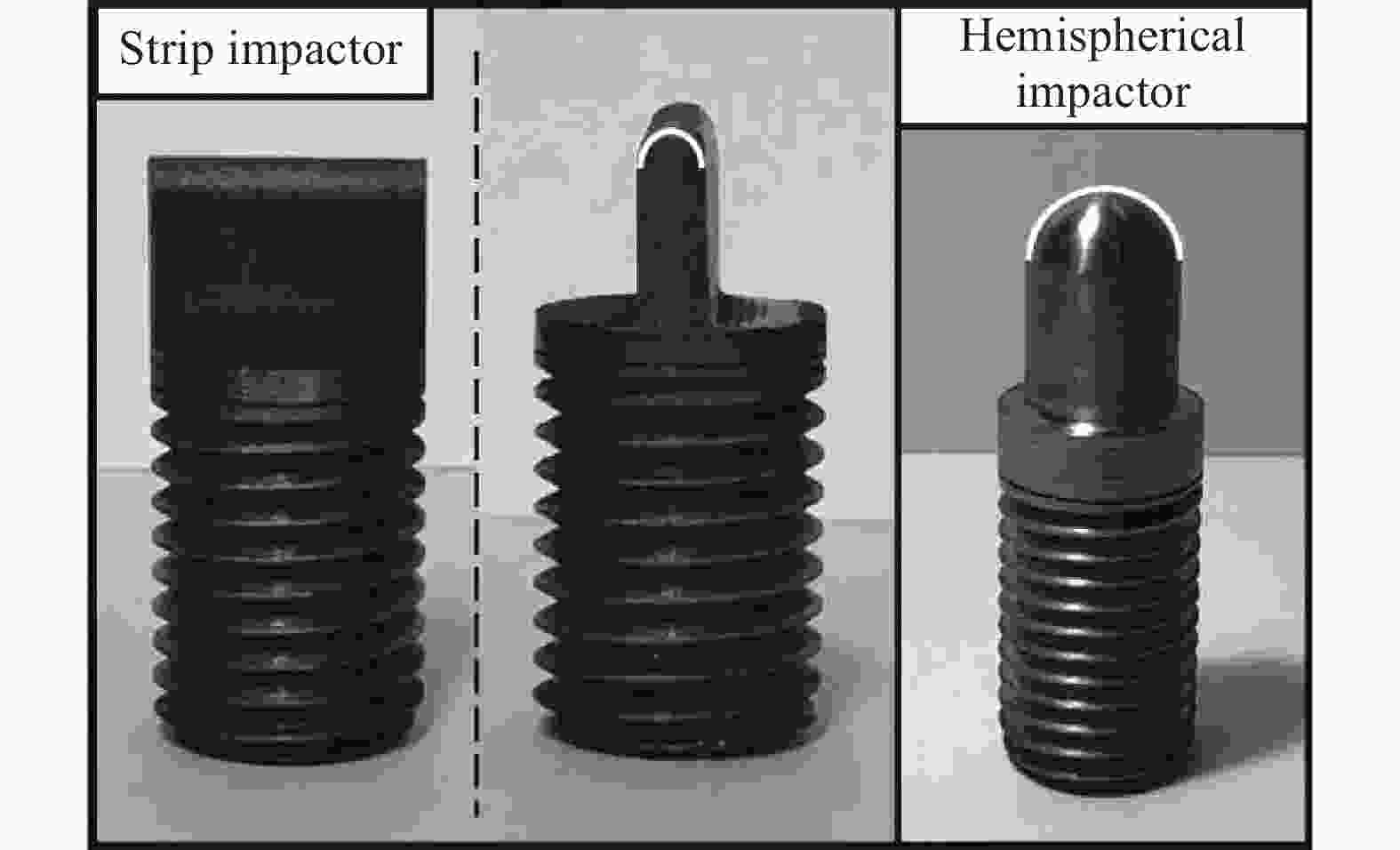

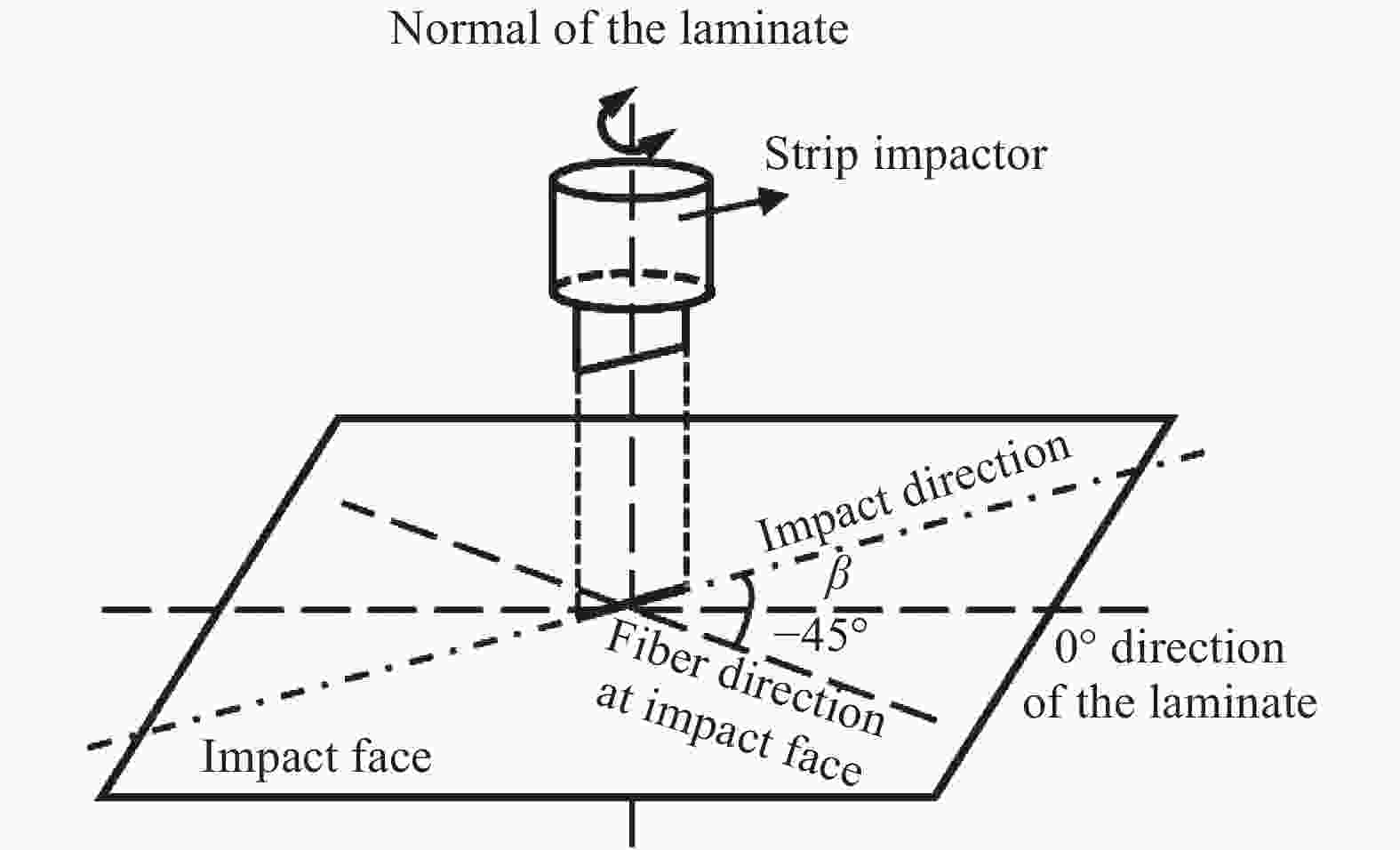

Test Key factor Type Impactor parameter Impactor energy/J Impactor velocity/

(m∙s−1)Times 1 Impactor angle S–45

S0

S45Strip impactor, –45°

Strip impactor, 0°

Strip impactor, 45°10 1.88 2 2 Impactor diameter H10

H14

H16Hemispherical impactor, 10 mm

Hemispherical impactor, 14 mm

Hemispherical impactor, 16 mm10 1.88 2 表 2 冲击损伤测试结果

Table 2. Summary of the impact test results

Specimen Dent depth/mm Delamination damage area/mm2 Specimen Dent depth/mm Delamination damage area/mm2 S–45 0.22 2147 H10 0.30 1613 S0 0.19 1710 H14 0.23 1553 S45 0.17 1651 H16 0.21 1230 -

[1] LIU P F, LIAO B B, JIA L Y, et al. Finite element analysis of dynamic progressive failure of carbon fiber composite laminates under low velocity impact [J]. Composite Structures, 2016, 149: 408–422. doi: 10.1016/j.compstruct.2016.04.012 [2] LIAO B B, LIU P F. Finite element analysis of dynamic progressive failure properties of GLARE hybrid laminates under low-velocity impact [J]. Journal of Composite Materials, 2018, 52(10): 1317–1330. doi: 10.1177/0021998317724216 [3] SCHOEPPNER G A, ABRATE S. Delamination threshold loads for low velocity impact on composite laminates [J]. Composites Part A: Applied Science and Manufacturing, 2000, 31(9): 903–915. doi: 10.1016/S1359-835X(00)00061-0 [4] YANG B, WANG Z, ZHOU L, et al. Experimental and numerical investigation of interply hybrid composites based on woven fabrics and PCBT resin subjected to low-velocity impact [J]. Composite Structures, 2015, 132: 464–476. doi: 10.1016/j.compstruct.2015.05.069 [5] WAN Y, DIAO C, YANG B, et al. GF/epoxy laminates embedded with wire nets: a way to improve the low-velocity impact resistance and energy absorption ability [J]. Composite Structures, 2018, 202: 818–835. doi: 10.1016/j.compstruct.2018.04.041 [6] 钭李昕, 王秋成, 陈光耀. 碳纤维复合材料低速冲击特性及损伤分析研究 [J]. 机电工程, 2016, 33(7): 815–821.TOU L X, WANG Q C, CHEN G Y. Analysis on low velocity impact performance and damage behavior of carbon fiber composite beam [J]. Journal of Mechanical & Electrical Engineering, 2016, 33(7): 815–821. [7] 竺铝涛, 张发. 碳纤维复合材料层压板低速冲击试验研究 [J]. 航空发动机, 2015, 41(1): 85–88.ZHU L T, ZHANG F. Experimental investigation of low-speed impact for carbon fiber composite laminate [J]. Aeroengine, 2015, 41(1): 85–88. [8] TAN W, FALZON B G, CHIU L N S, et al. Predicting low velocity impact damage and compression-after-impact (CAI) behaviour of composite laminates [J]. Composites Part A: Applied Science and Manufacturing, 2015, 71: 212–226. doi: 10.1016/j.compositesa.2015.01.025 [9] DUBARY N, BOUVET C, RIVALLANT S, et al. Damage tolerance of an impacted composite laminate [J]. Composite Structures, 2018, 206: 261–271. doi: 10.1016/j.compstruct.2018.08.045 [10] 姚振华, 李亚智, 刘向东, 等. 复合材料层合板低速冲击后剩余压缩强度研究 [J]. 西北工业大学学报, 2012, 30(4): 518–523. doi: 10.3969/j.issn.1000-2758.2012.04.008YAO Z H, LI Y Z, LIU X D, et al. Effectively calculating residual compressive strength of composite laminate after impact(CAI) [J]. Journal of Northwestern Polytechnical University, 2012, 30(4): 518–523. doi: 10.3969/j.issn.1000-2758.2012.04.008 [11] MITREVSKI T, MARSHALL I H, THOMSON R, et al. The effect of impactor shape on the impact response of composite laminates [J]. Composite Structures, 2005, 67(2): 139–148. doi: 10.1016/j.compstruct.2004.09.007 [12] AMARO A M, REIS P N B, MAGALHÃES A G, et al. The effect of the impactor diameter and boundary conditions on low velocity impact composites behavior [J]. Applied Mechanics and Materials, 2007, 7/8: 217–222. doi: 10.4028/www.scientific.net/AMM.7-8 [13] ICTEN B M, KIRAL B G, DENIZ M E. Impactor diameter effect on low velocity impact response of woven glass epoxy composite plates [J]. Composites Part B: Engineering, 2013, 50: 325–332. doi: 10.1016/j.compositesb.2013.02.024 [14] ANSARI M M, CHAKRABARTI A. Effect of boundary condition and impactor nose angle on impact behaviour of FRP composite: experimental and FE analyses [J]. Materials Today: Proceedings, 2017, 4(9): 9645–9649. doi: 10.1016/j.matpr.2017.06.241 [15] XIE W B, ZHANG W, KUANG N H, et al. Experimental investigation of normal and oblique impacts on CFRPs by high velocity steel sphere [J]. Composites Part B: Engineering, 2016, 99: 483–493. doi: 10.1016/j.compositesb.2016.06.020 [16] SEBAEY T A, GONZÁLEZ E V, LOPES C S, et al. Damage resistance and damage tolerance of dispersed CFRP laminates: effect of ply clustering [J]. Composite Structures, 2013, 106: 96–103. doi: 10.1016/j.compstruct.2013.05.052 [17] WANG H R, LONG S C, ZHANG X Q, et al. Study on the delamination behavior of thick composite laminates under low-energy impact [J]. Composite Structures, 2018, 184: 461–473. doi: 10.1016/j.compstruct.2017.09.083 [18] SHI Y, SWAIT T, SOUTIS C. Modelling damage evolution in composite laminates subjected to low velocity impact [J]. Composite Structures, 2012, 94(9): 2902–2913. doi: 10.1016/j.compstruct.2012.03.039 [19] XU Z, YANG F, GUAN Z W, et al. An experimental and numerical study on scaling effects in the low velocity impact response of CFRP laminates [J]. Composite Structures, 2016, 154: 69–78. doi: 10.1016/j.compstruct.2016.07.029 [20] ASTM International. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136/D7136M-15 [S]. West Conshohocken, PA: ASTM International, 2015. -

下载:

下载: