Constitutive Model of Aluminum Foams Considering Temperature Effect under Quasi-Static Compression

-

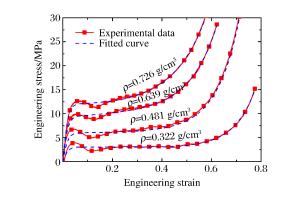

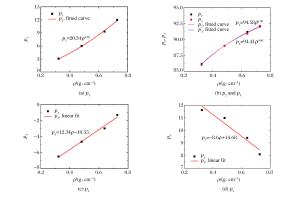

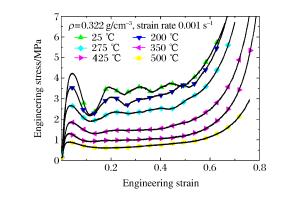

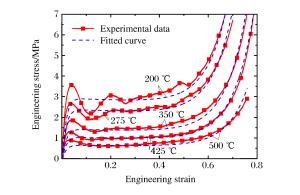

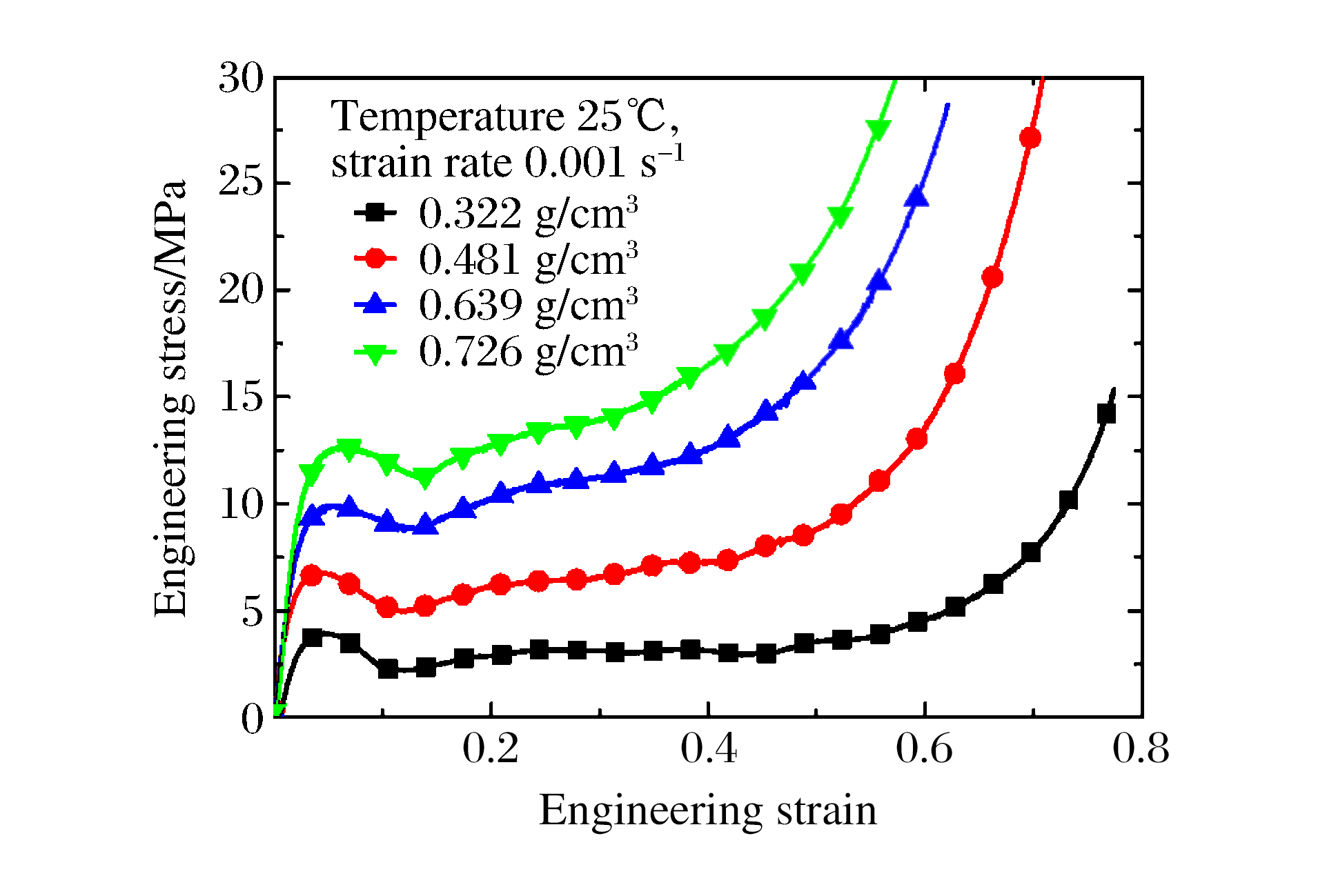

摘要: 采用MTS材料试验机研究了不同密度(0.322~0.726g/cm3)的闭孔泡沫铝在温度范围25~500℃下的准静态压缩力学性能,得到了泡沫铝在不同温度下的单轴压缩应力-应变曲线,分析了密度以及温度对其力学行为的影响。利用Liu和Subhash提出的本构模型对不同密度泡沫铝的应力-应变曲线进行拟合,分析并确定了模型中各参数随密度变化的函数,再代入Liu-Subhash模型,得到了泡沫铝的准静态压缩本构模型。通过引入温度软化项对准静态压缩本构模型进行修正,建立了考虑温度效应的泡沫铝准静态压缩本构模型,对闭孔泡沫铝的工程应用具有指导意义。Abstract: In this study, we employed the MTS machine to apply a compressive load to the closed cell aluminum foams with different densities (0.322-0.726g/cm3) at different temperatures (25-500℃) under quasi-static state, and obtained the stress-strain curves of the aluminum foam under uniaxial compression and analyzed the influence of density and temperature on its mechanical behavior.We fitted the stress-strain curves at different densities using the Liu and Subhash constitutive model, and the fitted results accorded well with the experimental curves.Then we analyzed and determined the function between the revised 5 parameters and the varying density, and established a constitutive model of the aluminum foams with density effect taken into consideration.With the temperature softening effect added to the modification of this constitutive model, we eventually established a constitutive model of aluminum foams considering both the temperature effect and the density effect under quasi-static compression.

-

表 1 不同密度下的模型参数值

Table 1. Parameter values for different densities

Density/(g·cm-3) Parameter p1 p2 p3 p4 p5 0.322 3.08 86.09 86.22 -6.49 11.60 0.481 5.98 90.83 90.74 -4.66 10.98 0.639 9.31 91.20 90.89 -3.00 9.41 0.726 12.01 92.04 92.14 -1.33 7.41 -

[1] 刘培生, 李铁藩, 傅超.多孔金属材料的应用[J].功能材料, 2001, 32(1):12-15. http://www.cqvip.com/QK/72003x/201607/epub1000000248429.htmlLIU P S, LI T F, FU C.Application of porous metal materials[J].Functional Materials, 2001, 32(1):12-15. http://www.cqvip.com/QK/72003x/201607/epub1000000248429.html [2] 尚朝秋, 王应武.泡沫铝材料研究现状分析[J].云南冶金, 2016, 45(3):10-13. http://www.cqvip.com/QK/90321B/201603/669250357.htmlSHANG Z Q, WANG Y W.The research status analysis of aluminum foam material[J].Yunnan Metallurgy, 2016, 45(3):10-13. http://www.cqvip.com/QK/90321B/201603/669250357.html [3] CHEN C, LU T J.A phenomenological framework of constitutive modelling for incompressible and compressible elastic-plastic solids[J].International Journal of Solids and Structures, 2000, 37(52):7769-7786. doi: 10.1016/S0020-7683(00)00003-2 [4] 王二恒, 虞吉林, 王飞, 等.泡沫铝材料准静态本构关系的理论和实验研究[J].力学学报, 2004, 36(6):673-679. http://mall.cnki.net/magazine/Article/LXXB200406004.htmWANG E H, YU J L, WANG F, et al.A theoretical and experimental study on the quasi-static constitutive model of aluminum foams[J].Acta Mechanica Sinica, 2004, 36(6):673-679. http://mall.cnki.net/magazine/Article/LXXB200406004.htm [5] WANG Z H, JING L, ZHAO L M.Elasto-plastic constitutive model of aluminum alloy foam subjected to impact loading[J].Transactions of Nonferrous Metals Society of China, 2011, 21(3):449-454. doi: 10.1016/S1003-6326(11)60735-8 [6] HAKAMADA M, NOMURA T, YAMADA Y, et al.Compressive deformation behavior at elevated temperatures in a closed-cell aluminum foam[J].Materials Transactions, 2005, 46(7):1677-1680. doi: 10.2320/matertrans.46.1677 [7] ALY M S.Behavior of closed cell aluminum foams upon compressive testing at elevated temperatures:experimental results[J].Materials Letters, 2007, 61(14):3138-3141. http://www.sciencedirect.com/science/article/pii/S0167577X06013206 [8] CADY C M, Ⅲ G T G, LIU C, et al.Compressive properties of a closed-cell aluminum foam as a function of strain rate and temperature[J].Materials Science and Engineering A, 2001, 525(1):1-6. http://www.sciencedirect.com/science/article/pii/S0921509309007503 [9] 习会峰, 刘逸平, 汤立群, 等.考虑温度效应的泡沫铝静态压缩本构模型[J].哈尔滨工程大学学报, 2013, 34(8):1000-1005. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hebgcdxxb201308010XI H F, LIU Y P, TANG L Q, et al.Constitutive model of aluminum foam with temperature effect under the quasi-static compression[J].Journal of Harbin Engineering University, 2013, 34(8):1000-1005. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hebgcdxxb201308010 [10] 王鹏飞, 徐松林, 胡时胜.基于温度与应变率相互耦合的泡沫铝本构关系[J].高压物理学报, 2014, 28(1):23-28. doi: 10.11858/gywlxb.2014.01.004WANG P F, XU S L, HU S S.A constitutive relation of aluminum foam coupled with temperature and strain rate[J].Chinese Journal of High Pressure Physics, 2014, 28(1):23-28. doi: 10.11858/gywlxb.2014.01.004 [11] LIU Q, SUBHASH G.A phenomenological constitutive model for foams under large deformations[J].Polymer Engineering and Science, 2004, 44(3):463-473. doi: 10.1002/(ISSN)1548-2634 -

下载:

下载: