Tensile Properties of CFRP/Epoxy Gel Composite Strip

-

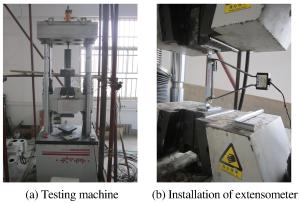

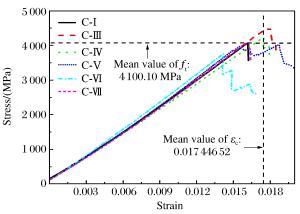

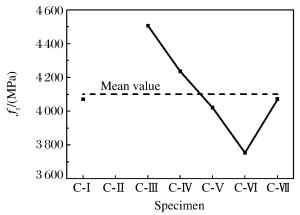

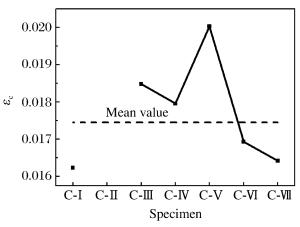

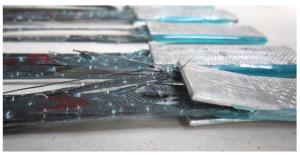

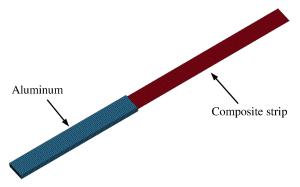

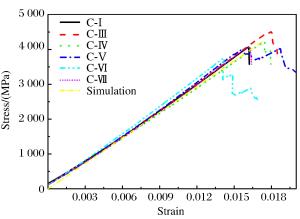

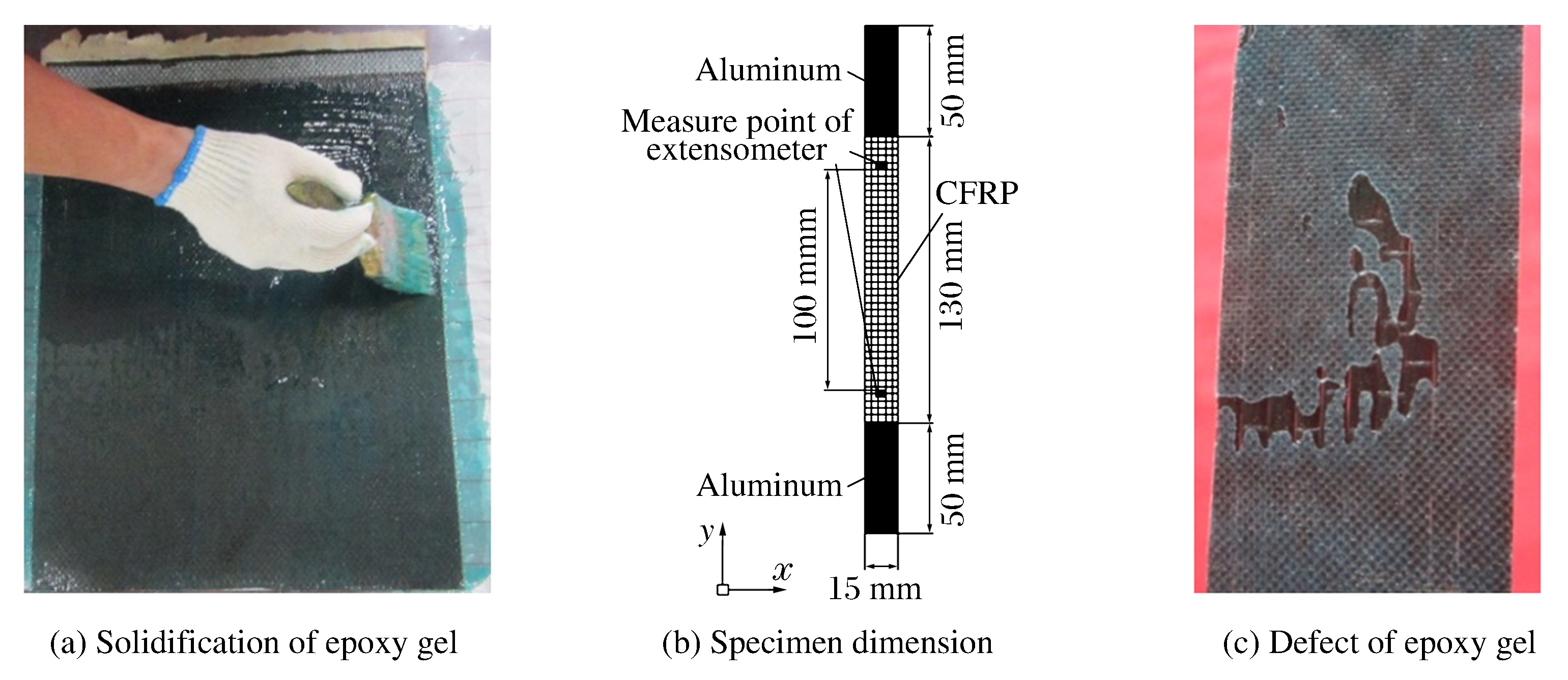

摘要: 碳纤维聚合物(CFRP)编织布和环氧树脂胶已被广泛应用于工程结构的外贴抗爆加固。为了了解CFRP布/树脂胶复合成型材料的基本力学性能,系统开展了标准复合条带试件的准静态拉伸力学试验,得到了拉伸应力-应变全过程曲线,并基于试验结果标定了有限元模型的关键材料参数。研究结果表明:CFRP布/树脂胶复合成型材料呈现明显的弹脆性特点,抗拉强度能够达到4 100 MPa,外贴树脂胶能够显著降低CFRP布力学性能指标的离散性,保证CFRP布材料特性的充分发挥;初始树脂粘贴缺陷对条带试件的破坏形态和抗拉性能有显著影响,外贴树脂胶的施工均匀度对加固工程结构的抗爆性能至关重要。Abstract: Carbon fiber reinforced polymer (CFRP) laminates and epoxy gels have been extensively applied to externally strengthen engineering structures to resist blast loading.In order to understand the mechanical properties of CFRP/epoxy gel composites, we carried out a series of quasi-static tensile tests and obtained the entire tensile stress-strain curve.Based on the test results, we calibrated the material parameters of the finite element model developed in LS-DYNA software.It is found that CFRP/epoxy gel composites exhibit an obvious elastic-brittle characteristic, and the mean value of the tensile strength obtained in the test is up to 4 100 MPa.Being externally attached with resin gel, the disadvantage of discrete characteristics of CFRP laminates was significantly improved, which makes the externally bonded CFRP fully effective.The initial defects of the pasted epoxy gels significantly affect the failure modes and tensile properties of the tested specimen, and the uniformity of the sprayed layer of epoxy gels is of great importance to improving the blast resistance of the retrofitted engineering structures.

-

Key words:

- carbon fiber reinforced polymer /

- resin gel /

- stress-strain entire curve /

- tensile test

-

表 1 拉伸试验结果

Table 1. Results of tensile test

Test No. ft/(MPa) E/(GPa) εc ηc/(%) C-Ⅰ 4 070.57 (-0.96%) 202.26 0.016 233 83 (-8.15%) 1.62 C-Ⅱ — — — — C-Ⅲ 4 506.13 (9.63%) 210.04 0.018 479 13 (4.55%) 1.84 C-Ⅳ 4 236.29 (3.07%) 205.77 0.017 956 60 (1.60%) 1.79 C-Ⅴ 4 021.92 (-2.15%) 211.07 0.020 028 14 (13.32%) 2.00 C-Ⅵ 3 754.01 (-8.66%) 227.65 0.016 929 41 (-4.22%) 1.69 C-Ⅶ 4 071.60 (-0.94%) 215.95 0.016 420 93 (-7.09%) 1.64 Mean value 4 100.10 212.12 0.017 446 52 1.74 Note:(1) Data in the brackets are the relative error to the mean value;

(2) Test results for specimen C-Ⅱ are not recorded due to technical error. -

[1] GAO P, GU X L, MOSALLAM A S.Flexural behavior of preloaded reinforced concrete beams strengthened by prestressed CFRP laminates[J].Compos Struct, 2016, 157:33-50. doi: 10.1016/j.compstruct.2016.08.013 [2] KHELIFA M, CELZARD A, OUDJENE M, et al.Experimental and numerical analysis of CFRP-strengthened finger-jointed timber beams[J].Int J Adhes Adhes, 2016, 68:283-297. doi: 10.1016/j.ijadhadh.2016.04.007 [3] AL CHAMI G, THÉRIAULT M, NEALE K W.Creep behavior of CFRP-strengthened reinforced concrete beams[J].Constr Build Mater, 2009, 23(4):1640-1652. doi: 10.1016/j.conbuildmat.2007.09.006 [4] 徐明, 姜岩宁, 陈忠范.碳纤维加固钢筋混凝土板耐火性能试验研究[J].防灾减灾工程学报, 2013, 33(3):323-328. http://d.old.wanfangdata.com.cn/Thesis/Y1386195XU M, JIANG Y N, CHEN Z F.Experimental study on reinforced concrete slabs strengthened with CFRP in fire[J].Journal of Disaster Prevention and Mitigation Engineering, 2013, 33(3):323-328. http://d.old.wanfangdata.com.cn/Thesis/Y1386195 [5] FATHELBAB F A, RAMADAN M S, AL-TANTAWY A.Strengthening of RC bridge slabs using CFRP sheets[J].Alex Eng J, 2014, 53(4):843-854. doi: 10.1016/j.aej.2014.09.010 [6] 徐玉野, 林燕卿, 杨清文, 等.CFRP加固火灾后混凝土短柱抗震性能的试验研究[J].工程力学, 2014, 31(8):92-100. http://cdmd.cnki.com.cn/Article/CDMD-10385-1014079299.htmXU Y Y, LIN Y Q, YANG Q W, et al.Experimental study on seismic performance of concrete short columns after fire and strengthened with CFRP[J].Engineering Mechanics, 2014, 31(8):92-100. http://cdmd.cnki.com.cn/Article/CDMD-10385-1014079299.htm [7] 龚永智, 张继文.CFRP筋增强混凝土偏心受压柱受力性能的试验研究[J].土木工程学报, 2009, 42(10):46-52. doi: 10.3321/j.issn:1000-131X.2009.10.007GONG Y Z, ZHANG J W.Experimental study of reinforced concrete eccentric compression column with CFRP tendons[J].China Civil Engineering Journal, 2009, 42(10):46-52. doi: 10.3321/j.issn:1000-131X.2009.10.007 [8] LI X, LIANG Y S, ZHAO Z H, et al.Low-cycle fatigue behavior of corroded and CFRP-wrapped reinforced concrete columns[J].Constr Build Mater, 2015, 101:902-917. doi: 10.1016/j.conbuildmat.2015.10.063 [9] CHEN L, FANG Q, FAN J Y, et al.Responses of masonry infill walls retrofitted with CFRP, steel mesh and steel bars to blast loadings[J].Adv Struct Eng, 2014, 17(6):817-836. doi: 10.1260/1369-4332.17.6.817 [10] CHEN L, FANG Q, JIANG C, et al.Response and damage level of confined masonry walls to blast[J].Disa Adv, 2013, 6(S4):380-394. [11] ZHANG X H, HAO H, SHI Y C, et al.Static and dynamic material properties of CFRP/epoxy laminates[J].Constr Build Mater, 2016, 114:638-649. doi: 10.1016/j.conbuildmat.2016.04.003 [12] OU Y F, ZHU D J, ZHANG H A, et al.Mechanical properties and failure characteristics of CFRP under intermediate strain rates and varying temperatures[J].Compos B:Eng, 2016, 95:123-136. doi: 10.1016/j.compositesb.2016.03.085 [13] HOU J P, RUIZ C.Measurement of the properties of woven CFRP T300/914 at different strain rates[J].Compos Sci Technol, 2000, 60(15):2829-2834. doi: 10.1016/S0266-3538(00)00151-2 [14] PENG H, HAO H X, ZHANG J R, et al.Experimental investigation of the bond behavior of the interface between near-surface-mounted CFRP strips and concrete[J].Constr Build Mater, 2015, 96:11-19. doi: 10.1016/j.conbuildmat.2015.07.156 [15] 祝明桥, 蒋伟中, 池绍进.预应力混凝土箱梁CFRP应力增量全过程试验研究[J].湘潭大学自然科学学报, 2011, 33(4):38-44. doi: 10.3969/j.issn.1000-5900.2011.04.010ZHU M Q, JIANG W Z, CHI S J.Experimental study of full process of CFRP stress increment of prestressed concrete box girder[J].Natural Science Journal of Xiangtan University, 2011, 33(4):38-44. doi: 10.3969/j.issn.1000-5900.2011.04.010 [16] 曹靖, 王建国, 完海鹰.CFRP加固钢结构吊车梁疲劳有限元分析及应用[J].合肥工业大学学报(自然科学版), 2010, 33(1):85-88. doi: 10.3969/j.issn.1003-5060.2010.01.021CAO J, WANG J G, WAN H Y.Finite element analysis of fatigue of steel crane beam structures reinforced with CFRP and its application[J].Journal of Hefei University of Technology, 2010, 33(1):85-88. doi: 10.3969/j.issn.1003-5060.2010.01.021 [17] 刘汉楚, 黄振华.碳纤维布在加固设计中的应用[J].科技资讯, 2007, 12:43-44. http://d.old.wanfangdata.com.cn/Periodical/kjzx200712033LIU H C, HUANG Z H.Application of CFRP in strengthening design[J].Science and Technology Information, 2007, 12:43-44. http://d.old.wanfangdata.com.cn/Periodical/kjzx200712033 [18] 刘婷, 贾彬, 卢毅.CFRP加固体积型缺陷钢板承载力的影响因素试验研究[C]//第九届全国建设工程FRP应用学术交流会.重庆, 2015: 89-92.LIU T, JIA B, LU Y.Experimental research of the influence factors on the bearing capacity of CFRP strengthening on the steel plate with non-planar flaw[C]//The 9th National Construction Engineering Application of FRP Academic Communication.Chongqing, 2015: 89-92. [19] MUTALIB A A, HAO H.Development of p-I diagrams for FRP strengthened RC columns[J].Int J Impact Eng, 2011, 38:290-304. doi: 10.1016/j.ijimpeng.2010.10.029 -

下载:

下载: