Effect of CO2 Assisted UHP Treatment on Qualities of Complex Seasonings

-

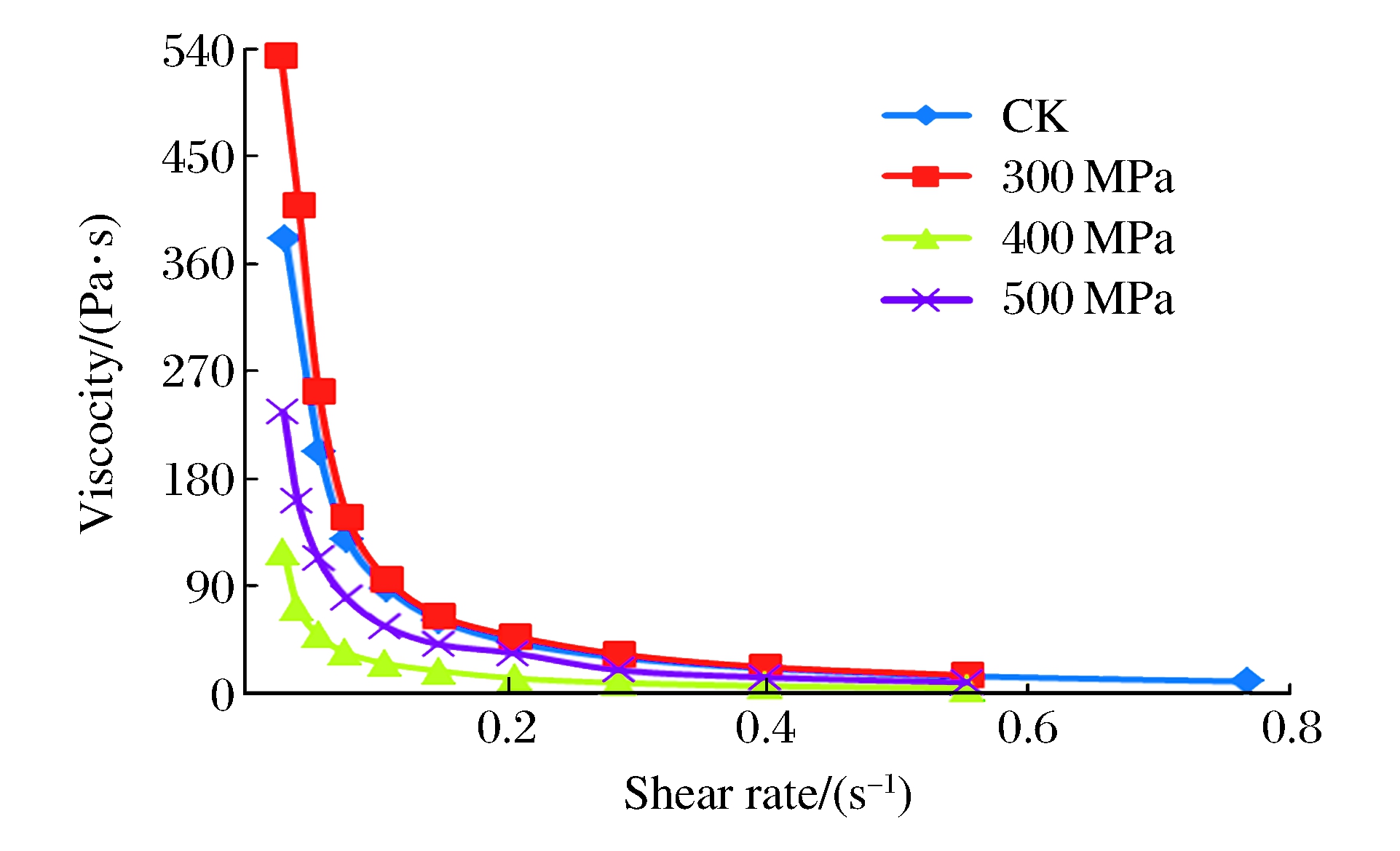

摘要: 超高压作为新兴的食品非热加工技术,使用方便、快捷,发展潜力巨大。选取3种具有代表性的复合调味料——复合黄豆酱、复合甜面酱及复合芝麻酱,研究CO2辅助超高压(300、400和500 MPa)处理对其细菌总数和黏度、颜色、风味等感官品质的影响。结果表明,经CO2辅助超高压处理后,3种复合酱料的细菌总数均减少,且压力越高,减少量越多,但均小于一个对数单位;黏度的变化无明显规律性;色泽方面,只有复合芝麻酱样品处理前、后出现较显著差异;风味物质的种类和含量方面,3种复合调味料均发生了不同程度的变化;感官评价结果显示,CO2辅助超高压处理对于复合调味料的整体感官品质无显著影响。研究表明,常温下CO2辅助500 MPa高压处理5 min的总体效果最好。研究结果可为超高压技术应用于调味料生产提供参考。Abstract: Ultra-high pressure (UHP) treatment, as a burgeoning non-thermal food-processing technology, is convenient and promises great potentialities for application in food industry.We selected 3 representative complex seasonings, composite soybean paste, composite sweet soybean paste and composite sesame paste, in our experiments to investigate the effect of CO2 assisted UHP treatments on their aerobic plate count, viscosity, color and flavor.The results show that, after CO2 assisted UHP treatment, the total bacteria number of all the 3 complex seasonings is reduced, and the higher the pressure, the greater the reduction, but the reductions are all less than one logarithmic unit.Our findings also show that there is no significant change in viscosity regularity between samples before and after the treatments, only the color of composite sesame paste samples undergoes significant changes, and the type and content of flavor compounds change with different degrees.Sensory evaluation reveals that at the 5% significant level, CO2 assisted UHP treatment shows no significant effect on complex seasonings.The treatment of 500 MPa, 5 min at room temperature is the optimum.This research provides reference for the application of UHP technology in seasonings production.

-

ΔEab* Sensation 0-0.5 Minute difference 0.5-1.5 Slight difference 1.5-3.0 Feel the difference 3.0-6.0 Significant difference 6.0-12.0 Obvious difference Above 12.0 Different color 表 2 CO2辅助不同超高压处理后复合调味料的细菌总数

Table 2. Total bacteria count (TBC) of complex seasonings under different CO2 assisted UHP treatments

Sample Pressure/

(MPa)TBC/

(106CFU/g)Composite

soybean

paste0 1.8±0.4 300 1.4±0.04 400 1.0±0.1 500 0.32±0.07 Composite

sweet

soybean

paste0 1.5±0.5 300 1.4±0.1 400 1.1±0.2 500 0.26±0.07 Composite

sesame

paste0 13.0±0.4 300 9.9±1.8 400 9.5±0.7 500 2.6±0.3 表 3 CO2辅助不同超高压处理前、后复合酱料的颜色变化

Table 3. Colors of complex seasonings under different CO2 assisted UHP treatments

Sample Pressure/(MPa) L* a* b* ΔEab0* ΔEab* Composite

soybean paste0 28.17 5.99 5.61 300 28.54 6.13 5.85 0.68 0.68 400 28.17 5.88 5.73 0.16 0.46 500 28.40 5.98 5.15 0.51 0.63 Composite

sweet soybean

paste0 23.78 1.95 0.90 300 23.62 2.03 0.65 0.31 0.31 400 23.34 1.89 0.88 0.44 0.39 500 23.37 2.14 1.32 0.51 0.51 Composite

sesame paste0 44.31 8.57 16.02 300 43.09 8.00 15.53 1.43 1.43 400 39.45 6.46 13.22 5.99 4.58 500 40.61 7.20 14.05 4.41 1.61 Note:ΔEab0* is the color difference of CO2 assisted UHP treated samples compared with CK, while ΔEab* is the color difference between treated samples (Compared with the previous group). 表 4 CO2辅助超高压处理前后复合黄豆酱关键香气成分的变化

Table 4. Changes of volatile fragrance compounds in composite soybean paste under different CO2 assisted UHP treatments

Volatile fragrance

compoundCK 300 MPa 400 MPa 500 MPa Qual/

(%)Area/

(%)Qual/

(%)Area/

(%)Qual/

(%)Area/

(%)Qual/

(%)Area/

(%)Octanoic acid,ethyl ester 89 0.70 - - 80 1.12 - - Pyrazine, tetramethyl- - - - - 87 1.03 91 1.29 Benzaldehyde 95 2.60 97 2.42 95 1.90 97 2.38 Benzeneacetaldehyde 93 3.13 92 1.36 92 2.54 93 3.21 Benzoic acid, ethyl ester 93 0.28 93 0.13 92 0.26 93 0.35 Oxime-, methoxy-phenyl-_ 91 15.71 91 9.80 91 13.15 91 13.32 Phenylethyl Alcohol 86 0.38 - - - - - - Ethanone, 1-(1H-pyrrol-2-yl)- 97 0.19 95 0.13 97 0.26 95 0.14 Eugenol - - 98 0.35 98 0.54 98 0.48 表 5 CO2辅助超高压处理前、后复合甜面酱关键香气成分的变化

Table 5. Changes of volatile fragrance compounds in composite sweet soybean paste under different CO2 assisted UHP treatments

Volatile fragrance

compoundCK 300 MPa 400 MPa 500 MPa Qual/

(%)Area/

(%)Qual/

(%)Area/

(%)Qual/

(%)Area/

(%)Qual/

(%)Area/

(%)Furfural 91 3.96 - - 91 1.58 91 2.19 Benzaldehyde 97 1.32 97 0.71 97 1.02 97 1.19 Benzeneacetaldehyde 87 3.36 92 2.84 93 3.92 89 2.82 Phenylethyl Alcohol - - 91 2.46 - - 91 2.61 Benzeneacetaldehyde, α-ethyl idene- 93 2.08 93 1.62 94 2.10 92 1.68 5-Methyl-2-phenyl-2-hexenal 99 19.68 99 17.26 99 22.33 99 16.78 Sorbic acid 96 8.33 96 5.40 97 6.07 96 7.70 Ethyl Oleate - - - - 97 0.25 99 0.35 Linoleic acid ethyl ester 99 0.46 99 0.91 99 1.07 99 1.28 表 6 CO2辅助超高压处理前、后复合芝麻酱关键香气成分的变化

Table 6. Changes of volatile fragrance compounds in composite sesame paste under different CO2 assisted UHP treatments

Volatile fragrance

compoundCK 300 MPa 400 MPa 500 MPa Qual/

(%)Area/

(%)Qual/

(%)Area/

(%)Qual/

(%)Area/

(%)Qual/

(%)Area/

(%)Dodecane - - - - 90 0.62 - - Dimethyl trisulfide 95 0.32 95 0.20 - - - - Pyrazine, 3-ethyl-2, 5-dimethyl- 95 2.89 95 2.85 95 2.33 95 2.97 Furfural 91 1.63 - - - - 91 1.67 Benzeneacetaldehyde 94 3.67 94 3.41 87 1.13 94 3.55 Oxime-, methoxy-phenyl-_ 91 13.32 91 13.70 87 22.51 91 14.90 表 7 CO2辅助不同超高压处理的复合酱料感官评价结果

Table 7. Sensory test results of complex seasonings under different CO2 assisted UHP treatments

Sample Color Viscosity Smell Taste Sorting of

overall

acceptanceSorting Forced

choiceSorting Forced

choiceSorting Forced

choiceSorting Forced

choiceComposite

soybean pasteN S1 S1>S2=S3>S0 S1 N N N N N Composite sweet

soybean pasteN N N N N N N N N Composite

sesame pasteN S1 S3>S2=S0>S1 N N N N N N Note:(1) “N” indicates that there is no significant difference between samples.

(2) S0 refers to CK, and S1-S3 are samples treated by CO2 assisted 300, 400 and 500 MPa UHP, respectively. -

[1] 邓成萍, 全明海, 张惠.复合调味料的研究进展[J].中国调味品, 2005(2): 7-10. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgtwp200502002Deng C P, Quan M H, Zhang H. Research progress of complex seasonings[J]. China Condiment, 2005(2): 7-10. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgtwp200502002 [2] 毛羽扬.复合型调味料的形成和发展[J].中国调味品, 2003(8): 3-6. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgtwp200308001Mao Y Y. The formation and development of compound flavoring materials[J]. China Condiment, 2003(8): 3-6. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgtwp200308001 [3] 夏远景, 薄纯智, 张胜勇, 等.超高压食品处理技术[J].食品与药品, 2006, 8(02A): 62-67. http://www.cnki.com.cn/article/cjfdtotal-sdpk200602021.htmXia Y J, Bo C Z, Zhang S Y, et al. High pressure technology for food processing[J]. Food and Drug, 2006, 8(02A): 62-67. (in Chinese) http://www.cnki.com.cn/article/cjfdtotal-sdpk200602021.htm [4] Yaldagard M, Mortazavi S A, Tabatabaie F. The principles of ultra high pressure technology and its application in food processing/preservation: A review of microbiological and quality aspects[J]. Afr J Biotechnol, 2008, 7(16): 2739-2767. http://www.oalib.com/paper/1325754 [5] 王莉.二氧化碳协同食品超高压杀菌研究[D].合肥: 合肥工业大学, 2012.Wang L. Research on inactivation of food bacteria by the combined treatment of carbon dioxide with high hydrostatic pressure[D]. Hefei: Hefei University of Technology, 2012. (in Chinese) [6] 中华人民共和国卫生部. GB 47892-2010食品安全国家标准食品微生物学检验: 菌落总数测定[S].北京: 中国标准出版社, 2010.Ministry of Health P. R. China. GB 47892-2010 National Food Safety Standard Food Microbiological Examination: Aerobic Plate Count[S]. Beijing: China Standard Press, 2010. (in Chinese) [7] 李里特.食品物性学[M].北京: 中国农业出版社, 1998: 182-193.Li L T. Physical Properties of Foods[M]. Beijing: China Agriculture Press, 1998: 182-193. (in Chinese) [8] 汪洪涛, 周艳红, 余芳.大豆皮水溶性多糖组成及其流变学性质研究[J].中国食品添加剂, 2012(5): 134-139. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgsptjj201205014Wang H T, Zhou Y H, Yu F. Study on the composition and rheological property of water-soluble polysaccharides from soybean hull[J]. China Food Additives, 2012(5): 134-139. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgsptjj201205014 [9] 纪滨, 许正华, 胡学钢, 等.基于颜色的食品品质检测技术现状及展望[J].食品与机械, 2013, 29(4): 229-232. http://www.cqvip.com/QK/90106A/201304/46712720.htmlJi B, Xu Z H, Hu X G, et al. Reviewing food quality detection technology based on color[J]. Food and Machinery, 2013, 29(4): 229-232. (in Chinese) http://www.cqvip.com/QK/90106A/201304/46712720.html [10] 汪浩明.食品检验技术(感官评价部分)[M].北京: 中国轻工业出版社, 2007: 58-67.Wang H M. Food Inspection Technology(Sensory Evaluation Section)[M]. Beijing: China Light Industry Press, 2007: 58-67. (in Chinese) [11] Garcia-Gonzalez L, Geeraerd A H, Spilimbergo S, et al. High pressure carbon dioxide inactivation of microorganisms in foods: The past, the present and the future[J]. Int J Food Microbiol, 2007, 117(1): 1-28. doi: 10.1016/j.ijfoodmicro.2007.02.018 [12] Wang L, Pan J, Xie H, et al. Inactivation of staphylococcus aureus and Escherichia coli by the synergistic action of high hydrostatic pressure and dissolved CO2[J]. Int J Food Microbiol, 2010, 144(1): 118-125. doi: 10.1016/j.ijfoodmicro.2010.09.006 [13] Molin G. The resistance to carbon dioxide of some food related bacteria[J]. Euro J Appl Microb Biot, 1983, 18(4): 214-217. doi: 10.1007/BF00501511 [14] 王莉.二氧化碳协同食品超高压杀菌研究[D].合肥: 合肥工业大学, 2012.Wang L. Research on inactivation of food bacteria by the combined treatment of carbon dioxide with high hydrostatic pressure[D]. Hefei: Heifei University of Technology, 2012. [15] 丁祥瑞, 汪建明.超高压对酱料食品中微生物指标的影响[J].中国食品添加剂, 2012(1): 143-147. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgsptjj2012z1030Ding X R, Wang J M. Effect of ultra high pressure on microbial indicators of food sauce[J]. China Food Additives, 2012(1): 143-147. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgsptjj2012z1030 [16] 郑咸金.豆酱的营养[J].新疆农业科技, 1993(6): 39. http://www.cnki.com.cn/Article/CJFDTotal-XJNK199306027.htmZheng X J. Nutrition of soybean paste[J]. Xinjiang Agricultural Science and Technology, 1993(6): 39. (in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-XJNK199306027.htm [17] 张宏康.超高压对生物大分子的影响研究[D].北京: 中国农业大学, 2001.Zhang H K. High pressure effects on biomacromolecules[D]. Beijing: China Agricultural University, 2001. (in Chinese) [18] 黄丽, 孙远明, 潘科, 等.超高压处理对荔枝果汁品质的影响[J].农业工程学报, 2007, 23(2): 259-262. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nygcxb200702050Huang L, Sun Y M, Pan K, et al. Influence of ultra high pressure treatment on the quality of lychee juice[J]. Transactions of the CSAE, 2007, 23(2): 259-262. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nygcxb200702050 [19] 任广鸣.芝麻酱的化学成分及营养[J].粮食加工, 1987(3): 2-5. http://www.cnki.com.cn/Article/CJFDTotal-XBLY198703000.htmRen G M. Chemical composition and nutrition of sesame paste[J]. Grain Processing, 1987(3): 2-5. (in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-XBLY198703000.htm [20] 乔鑫.黄豆酱挥发性成分形成特征的研究[D].武汉: 湖北工业大学, 2011.Qiao X. Characteristic on volatile components forming during fermentation process of soybean paste[D]. Wuhan: Hubei University of Technology, 2011. (in Chinese) [21] 康旭, 孟鸳, 乔宇, 等.固相微萃取——气相色谱-质谱联用测定甜面酱挥发性成分条件的优化[J].中国调味品, 2010(12): 99-103. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgtwp201012023Kang X, Meng Y, Qiao Y, et al. Determination of volatile components from sweet flour paste by SPME-GC-MS[J]. China Condiment, 2010(12): 99-103. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgtwp201012023 [22] 张玉玉, 黄明泉, 田红玉, 等. "六必居"面酱挥发性成分SDE法提取及GC-MS分析[J].中国食品学报, 2010(2): 154-159. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgspxb201002023Zhang Y Y, Huang M Q, Tian H Y, et al. Extract and analysis of the volatile components of the Liubiju sweet sauce by SDE method and GC-MS[J]. Journal of China Institute of Food Science and Technology, 2010(2): 154-159. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgspxb201002023 [23] 陈晓明, 朱鼎程.固相微萃取-气质联用分析芝麻油的挥发性成分的研究[J].安徽农业科学, 2010(2): 570-574. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ahnykx201002007Chen X M, Zhu D C. Analysis of volatile compounds in headspace of sesame seed oil using SPME/GC/MS[J]. Journal of Anhui Agricultural Sciences, 2010(2): 570-574. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ahnykx201002007 [24] 秦早.芝麻油风味物质分析研究[D].郑州: 郑州大学, 2012.Qin Z. Analysis research of the volatile compounds in sesame oil[D]. Zhengzhou: Zhengzhou University, 2012. (in Chinese) [25] 马蕊, 张爱霞, 生庆海. Friedman检验和Kramer检验在感官排序测试中的比较[J].中国乳品工业, 2007, 35(9): 14-16. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgrpgy200709004Ma R, Zhang A X, Sheng Q H. Comparison of Friedman test and Kramer testin sensory ranking test[J]. Dairy Industry, 2007, 35(9): 14-16. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgrpgy200709004 -

下载:

下载: